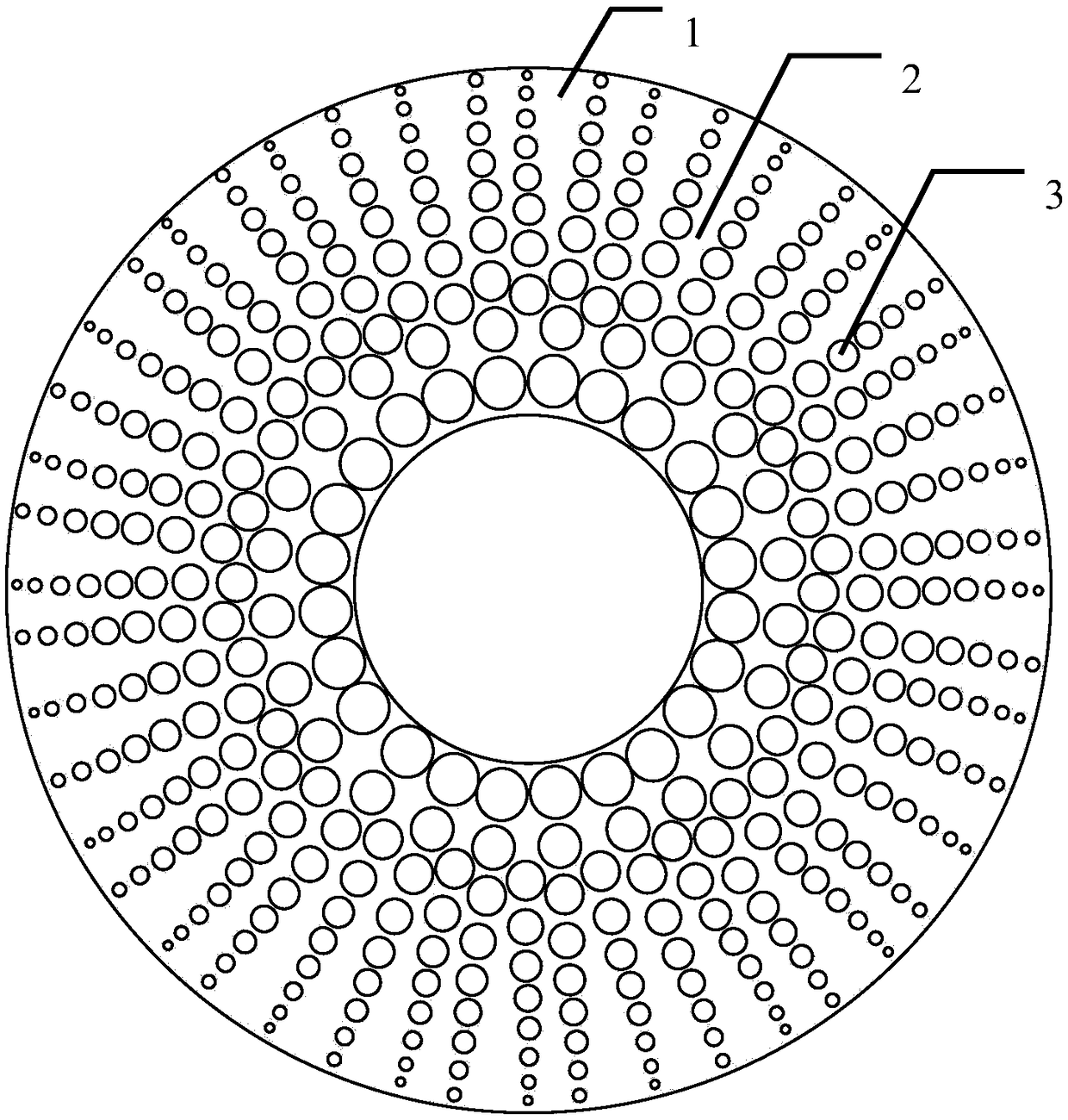

Tubular scaffold with double-layer structure and preparation method thereof

A double-layer structure, tubular technology, applied in the field of medical devices, can solve the problems of easily damaged tissue, delamination, complex operation, etc., and achieve the effect of promoting tissue ingrowth, inducing tissue regeneration, and meeting repair requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027]In a second aspect, the present invention provides a method for preparing a tubular stent with a double-layer structure, the method comprising the following steps: (1) emulsification and foaming: preparing a composite solution comprising polyvinyl alcohol and a natural polymer material, and then While stirring, add an emulsifier for emulsification and foaming to obtain a foaming emulsion; (2) crosslinking: after the foaming emulsion is stable, add a catalyst, and wait for the temperature to cool to 5-40°C (for example, 10°C, 15°C, 20°C , 25°C, 30°C or 35°C), add a cross-linking agent for cross-linking reaction to obtain a cross-linked emulsion; (3) Rotation curing: pour the cross-linked emulsion into a hollow cylindrical mold, seal it in a cylindrical shape The axial line of the mold is the center and rotates and solidifies to form a cylindrical sponge body; (4) demoulding, cleaning and punching: the cylindrical sponge body is demoulded and cleaned to neutrality, and then...

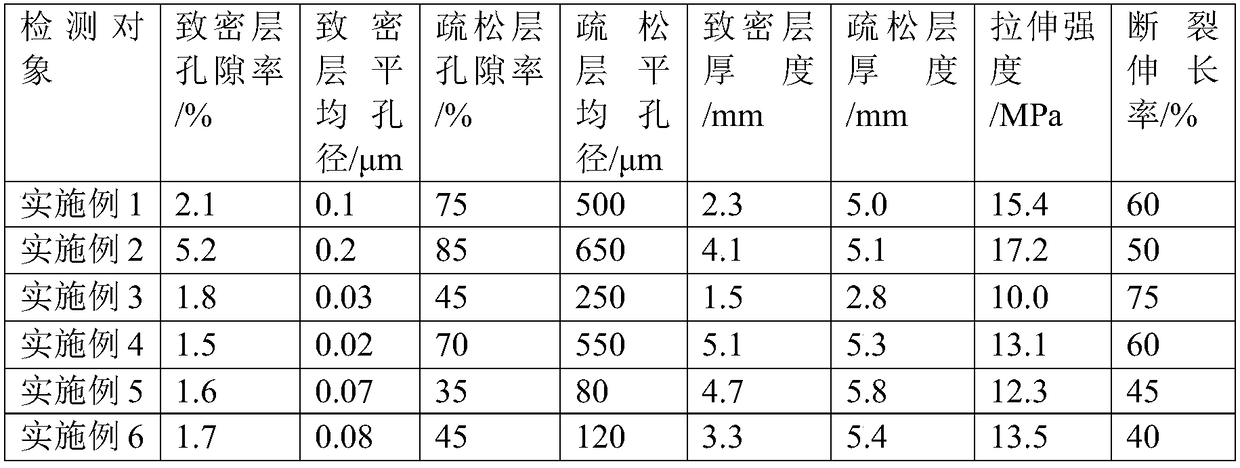

Embodiment 1

[0046] First, weigh 45 g of polyvinyl alcohol (polymerization degree 1700, alcoholysis degree 88%) and 10 g of gelatin and dissolve them in 300 ml of water to obtain a polyvinyl alcohol-gelatin solution. Then, while stirring, add 1ml of alkylphenol polyoxyethylene ether for emulsification and foaming. After the polyvinyl alcohol-gelatin emulsion is stable, slowly add 30ml of 30% sulfuric acid solution, continue stirring, and after cooling to 25°C, slowly Add 50ml of 37% formaldehyde solution to carry out cross-linking reaction. After adding the solution and continue to react for 20 minutes, inject the emulsion into a cylindrical mold (the material of the mold is polyethylene phthalate), seal it and put it on the rotating device , rotate along the axis of the cylindrical mold at a speed of 15 rpm and a temperature of 50°C. After 6 hours of rotation and curing, take out the film and obtain a cylindrical sponge. After washing with water to neutral pH, use wire cutting The machine...

Embodiment 2

[0048] First weigh 45g of polyvinyl alcohol (polymerization degree 2000, degree of alcoholysis 70%) and 15g of carboxymethyl chitosan dissolved in 300ml of water to obtain polyvinyl alcohol-carboxymethyl chitosan solution. Then, while stirring, add 1.2ml of alkylphenol polyoxyethylene ether for emulsification and foaming. After the polyvinyl alcohol-carboxymethyl chitosan emulsion is stable, slowly add 30ml of 30% sulfuric acid solution, continue stirring, and cool down After reaching 25°C, slowly add 45ml of 37% formaldehyde solution for cross-linking reaction. After adding the solution and continue to react for 20 minutes, inject the emulsion into a cylindrical mold (the material of the mold is plexiglass material), seal it and place it in a rotating device , rotate along the axis of the cylindrical mold at a speed of 10 rpm, and a temperature of 50°C. After 6 hours of rotational curing, take out the mold to obtain a cylindrical sponge, wash it with water to a neutral pH, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com