A kind of preparation method of oral amoxicillin pH-responsive nanocarrier and product thereof

A nano-carrier and amoxicillin technology, applied in the field of medical biomaterials, can solve the problems of cumbersome preparation process, long drug release time, gastric mucosal irritation, etc., to overcome complex operation and release difficulties, improve drug utilization, biological good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] (1) Preparation of γ-PGA / CS NPs: Add 0.1-5g / L polyglutamic acid aqueous solution dropwise to 0.1-1.0g / L chitosan at a rate of 2-10ml / h with a micro-injection pump In the aqueous solution, stir overnight at room temperature at 600-800rpm, adjust the pH to 2.5, 4.0, 5.0, 6.0, and 7.4 with 2M hydrochloric acid and 2M sodium hydroxide, and measure the potential and particle size at different pHs with a Malvern nanoparticle size analyzer.

[0031](2) Preparation of γ-PGA / CS-Amoxicillin NPs: Mix amoxicillin (1-4g / L) and 2-6g / L polyglutamic acid aqueous solution evenly, and use a micro-injection pump to mix the mixture according to 2- Add 10ml / h dropwise to 0.1-0.5g / L chitosan aqueous solution, stir overnight at room temperature, away from light, at 600-800rpm, place it in a dialysis bag (MWCO=8000-14000), and dialyze into the dialysate The UV absorption of amoxicillin was not detectable. Drug-loaded nanoparticles were obtained by freeze-drying, and the size and shape of γ-PG...

Embodiment 1

[0048] Preparation of γ-PGA / CS NPs(+) and γ-PGA / CS NPs(-):

[0049] Add 0.1-5g / L polyglutamic acid aqueous solution dropwise to chitosan aqueous solution with different concentrations (0.1-1.0g / L) at a rate of 2-10ml / h with a micro-syringe pump, at 25°C, 600- Stir at 800rpm overnight, adjust the pH to 2.5, 4.0, 5.0, 6.0, 7.4 with 2M hydrochloric acid and 2M sodium hydroxide, and measure the potential and particle size at different pHs with a Malvern Nanoparticle Sizer. Finally, two kinds of γ-PGA / CS NPs with a particle size of 200 nm and positive and negative charges on the surface were selected as the carrier for amoxicillin drug embedding. The particle size of γ-PGA / CSNPs was about 200 nm at pH 2.5, and at pH 7.4 is about 800nm.

[0050] Table 1: Effect of γ-PGA concentration on particle size of γ-PGA / CS NPs

[0051]

[0052]

[0053] Table 2: Effect of CS concentration on particle size of γ-PGA / CS NPs

[0054]

[0055] Table 3: Selection of drop rate

[0056] ...

Embodiment 2

[0065] Preparation of γ-PGA / CS-Amoxillin NPs(+) and γ-PGA / CS-Amoxicllin NPs(-):

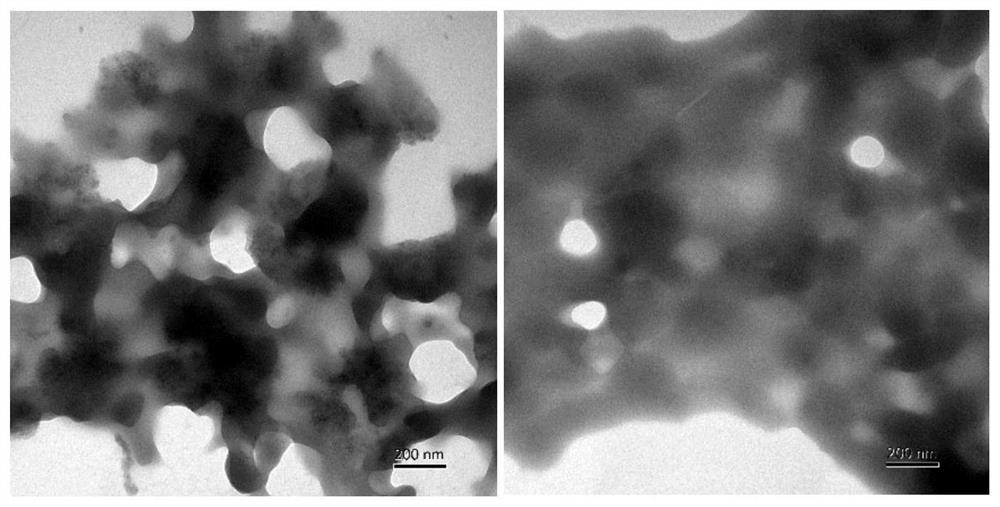

[0066] Amoxicillin (1-4g / L) and the molecular weight of 2-6g / L are the polyglutamic acid aqueous solution mixing more than 700,000 Daltons, according to the method for embodiment 1 its mixture is used micro-injection pump (needle) 0.1-0.2mm inner diameter, 0.2-0.6mm outer diameter) dropwise into 0.1-0.5g / L chitosan aqueous solution at 2-10ml / h, room temperature, dark, 600-800rpm stirring overnight to prepare γ-PGA / CS-Amoxicillin NPs, put it in a dialysis bag (MWCO=8000-14000) and dialyze until no UV absorption of amoxicillin can be detected in the dialysate, then freeze-dry to obtain γ-PGA / CS-AmoxicillinNPs loaded with amoxicillin , to observe its appearance with a scanning electron microscope, and at the same time dissolve it with a citric acid buffer solution of pH 2.5 to prepare a 1 mg / ml solution, and use a transmission electron microscope to observe the appearance of the solution. (Such as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com