Zirconium dioxide short fiber and basic magnesium sulfate whisker composite enhanced magnesia-based crucible and preparation method thereof

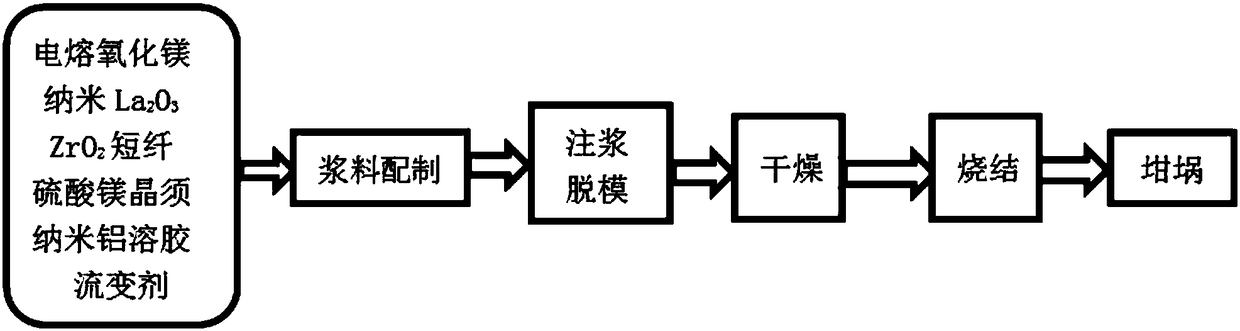

A technology of magnesium sulfate whiskers and zirconium dioxide, which is used in magnesium oxide-based crucibles and their preparation, smelting of magnesium and its alloys, and composite reinforced magnesium oxide-based crucibles with zirconium dioxide short fibers and basic magnesium sulfate whiskers. In the field of preparation, it can solve the problems of reducing the sintering temperature of magnesia ceramics, increasing the emission of gaseous fluoride, increasing the lattice distortion of the magnesia matrix, and achieving the effects of improving the density and mechanical properties, optimizing the mixing uniformity and the uniform wall thickness of the crucible.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] According to the mass percentage of nano-lanthanum oxide in the ceramic powder is 1%, zirconia short fiber is 0.5%, basic magnesium sulfate whisker is 1%, and the rest is the proportion of fused magnesia, the nanometer particle size is 60nm Lanthanum oxide, commercial zirconium dioxide short fibers (diameter 7 μm-10 μm, length 2 mm-3 mm), commercial magnesium basic sulfate whiskers (diameter about 1 μm, length 50 μm-100 μm) and particle size 250 mesh ( Middle diameter d 50Mix and prepare ceramic powder with fused magnesia powder (58 μm); mix and prepare rheological agent according to the mass ratio of urea-formaldehyde resin and hydroxyethyl cellulose at a ratio of 1:4.

[0057] According to mass percentage, 15% of nano-alumina sol with a solid content of 20% (select a commercial nano-alumina sol with a nearly neutral pH value, the same below), 0.8% of rheological agent, and the rest are ceramic powders for batching. First, add the fused magnesia powder into the ball m...

Embodiment 2

[0062] According to the ratio of nanometer lanthanum oxide to the mass percentage of ceramic powder as 3%, zirconium dioxide short fiber as 1%, basic magnesium sulfate whisker as 2%, and the rest as fused magnesia, the nanometer with a particle size of 30nm Lanthanum oxide, commercial zirconia short fibers (diameter 7μm-10μm, length 2mm-3mm), commercial magnesium basic sulfate whiskers (diameter about 1μm, length 50μm-100μm) and particle size 500 mesh ( Middle diameter d 50 Mix and prepare ceramic powder with fused magnesia powder (25 μm); mix and prepare rheological agent according to the mass ratio of urea-formaldehyde resin and hydroxypropyl cellulose at a ratio of 1:4.

[0063] According to mass percentage, 25% of nano-alumina sol with a solid content of 25%, 1.5% of rheological agent, and the rest are ceramic powder for batching. First, add the fused magnesia powder into the ball mill tank according to the ratio, prepare nano-aluminum sol, rheological agent and appropria...

Embodiment 3

[0068] According to the mass percentage of nano-lanthanum oxide in ceramic powder is 2%, zirconium dioxide short fiber is 0.7%, basic magnesium sulfate whisker is 1.5%, and the rest is electric fused magnesia, the particle size is 45nm nano Lanthanum oxide, commercial zirconia short fibers (diameter 7μm-10μm, length 2mm-3mm), commercial magnesium basic sulfate whiskers (diameter about 1μm, length 50μm-100μm) and particle size 325 mesh ( Middle diameter d 50 Mix and prepare ceramic powder with fused magnesia powder (45 μm); mix and prepare rheological agent according to the mass ratio of urea-formaldehyde resin and hydroxyethyl cellulose at a ratio of 1:4.

[0069] According to mass percentage, 20% of nano-alumina sol with a solid content of 22%, 1% of rheological agent, and the rest are ceramic powder for batching. First, add the fused magnesia powder into the ball mill tank according to the ratio, prepare nano-aluminum sol, rheological agent and appropriate amount of deioniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com