Road piezoelectric composite material and preparation method thereof

A piezoelectric composite material, road-use technology, applied in the direction of material selection for piezoelectric devices or electrostrictive devices, manufacturing/assembly of piezoelectric/electrostrictive devices, device material selection, etc., can solve the problem of composite materials Reduced piezoelectric and dielectric properties, poor anti-traffic load impact performance, and great impact on the ecological soil environment, etc., to achieve the effect of improving piezoelectric and dielectric properties, improving anti-traffic load impact performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

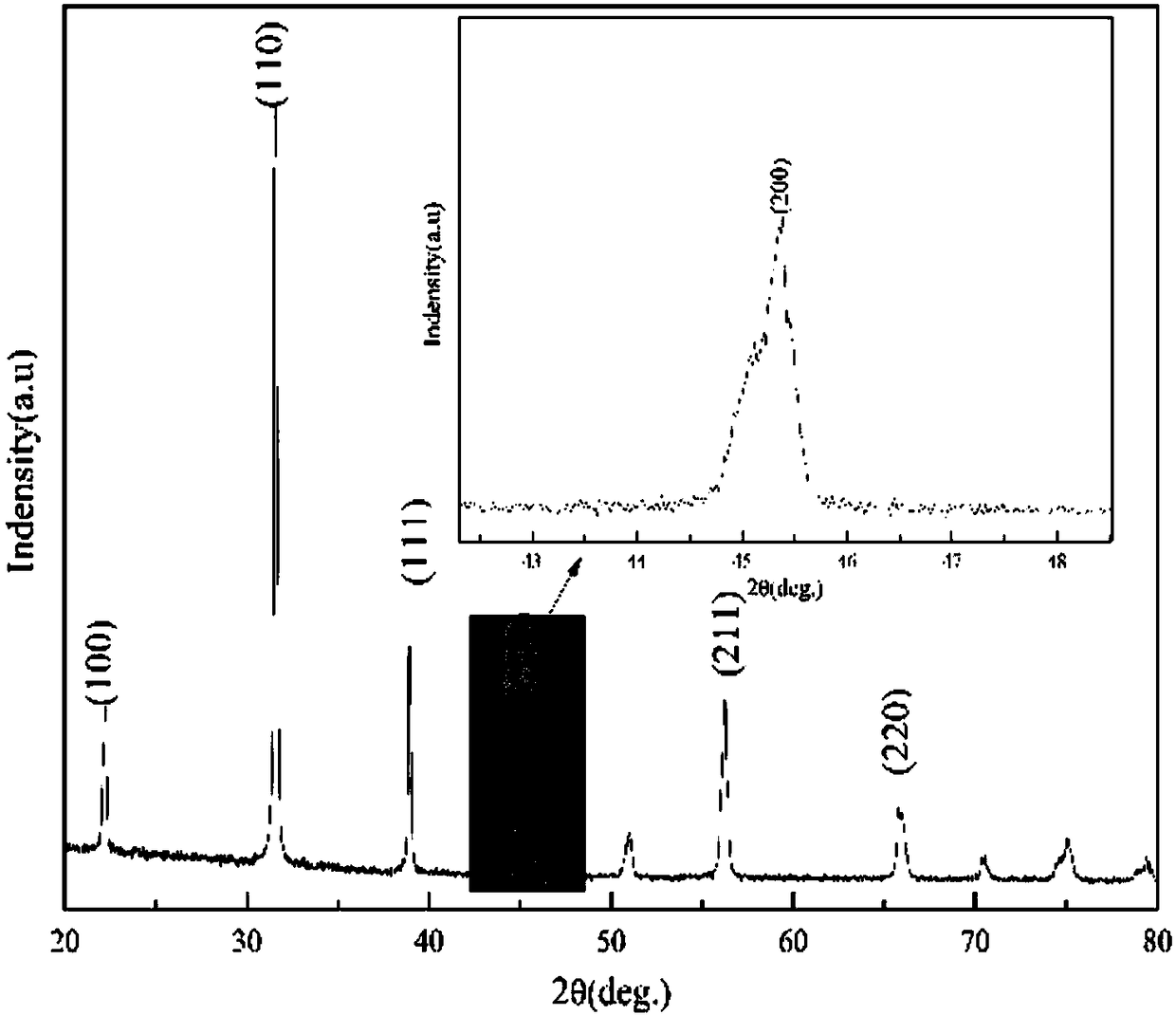

Embodiment 1

[0031] The road piezoelectric composite material of the present invention is composed of 70g of barium titanate and 32g of polyvinylidene fluoride.

[0032] The melting point Tm of polyvinylidene fluoride is 167°C, and the density ρ is 1.75g / cm 3 , The number average molecular weight of polyvinylidene fluoride is 825,000.

[0033] The preparation method of road piezoelectric composite material of the present invention comprises the following steps:

[0034] 1) Weigh polyvinylidene fluoride and barium titanate;

[0035] 2) Put polyvinylidene fluoride and barium titanate in a magnetic stirrer, add absolute ethanol to the magnetic stirrer, grind for 15 minutes, put them in an oven, and dry at 100°C for 75 minutes to obtain mixed powder;

[0036] 3) Put the mixed powder obtained in step 2) into a hot-pressed abrasive tool, heat it to 175°C and keep it warm for 60 minutes, then apply pressure to the mixed powder and keep the pressure for 30 minutes to obtain a sample;

[0037] ...

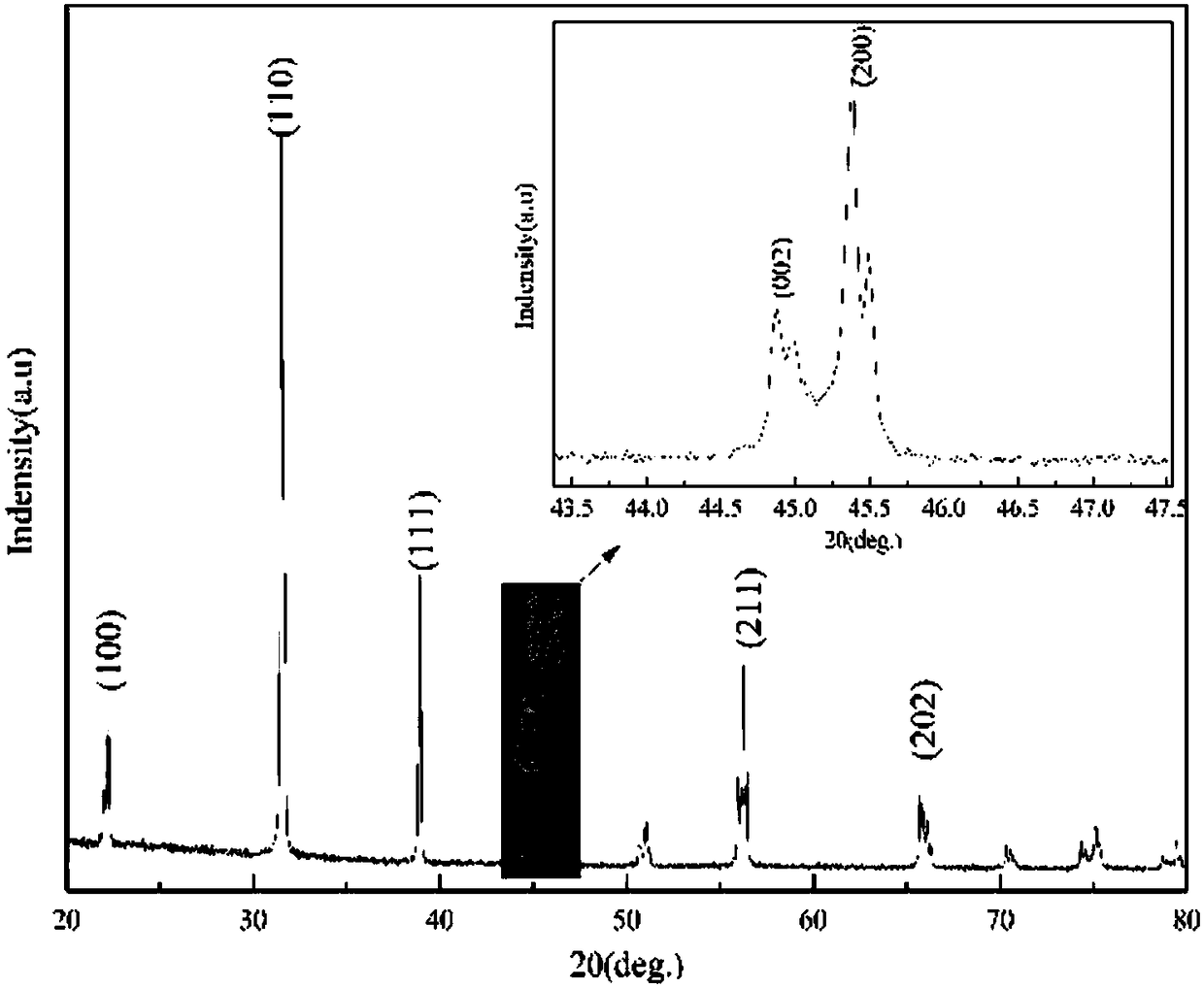

Embodiment 2

[0041] The road piezoelectric composite material of the present invention is made up of 75g of barium titanate and 32g of polyvinylidene fluoride;

[0042] The melting point Tm of polyvinylidene fluoride is 167°C, and the density ρ is 1.77g / cm 3 , The number average molecular weight of polyvinylidene fluoride is 825,000.

[0043] The preparation method of road piezoelectric composite material of the present invention comprises the following steps:

[0044] 1) Put the barium titanate in the corundum crucible, then raise the temperature of the corundum crucible to 850°C at a constant rate of 5°C / min; keep it warm for 90 minutes, and then cool down to room temperature;

[0045] 2) weighing polyvinylidene fluoride and the barium titanate obtained in step 1);

[0046] 3) Put polyvinylidene fluoride and barium titanate in a magnetic stirrer, then add absolute ethanol to the magnetic stirrer, grind for 10 minutes, put them in an oven, and dry at 100°C for 60 minutes to obtain mixe...

Embodiment 3

[0052] The road piezoelectric composite material of the present invention consists of 68g of barium titanate and 29g of polyvinylidene fluoride;

[0053] The melting point Tm of polyvinylidene fluoride is 167°C, and the density ρ is 1.76g / cm 3 , The number average molecular weight of polyvinylidene fluoride is 825,000.

[0054] The preparation method of road piezoelectric composite material of the present invention comprises the following steps:

[0055] 1) Put the barium titanate in the corundum crucible, then raise the temperature of the corundum crucible to 950°C at a constant speed of 10°C / min; keep it warm for 75min, and then cool down to room temperature;

[0056] 2) weighing polyvinylidene fluoride and the barium titanate obtained in step 1);

[0057] 3) Put polyvinylidene fluoride and barium titanate in a magnetic stirrer, add absolute ethanol to the magnetic stirrer, grind for 13 minutes, put them in an oven, and dry them at 100°C for 70 minutes to obtain mixed pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com