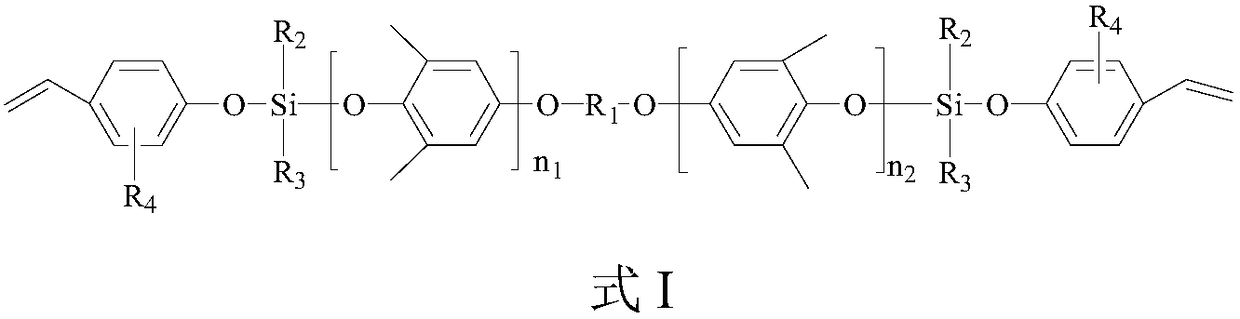

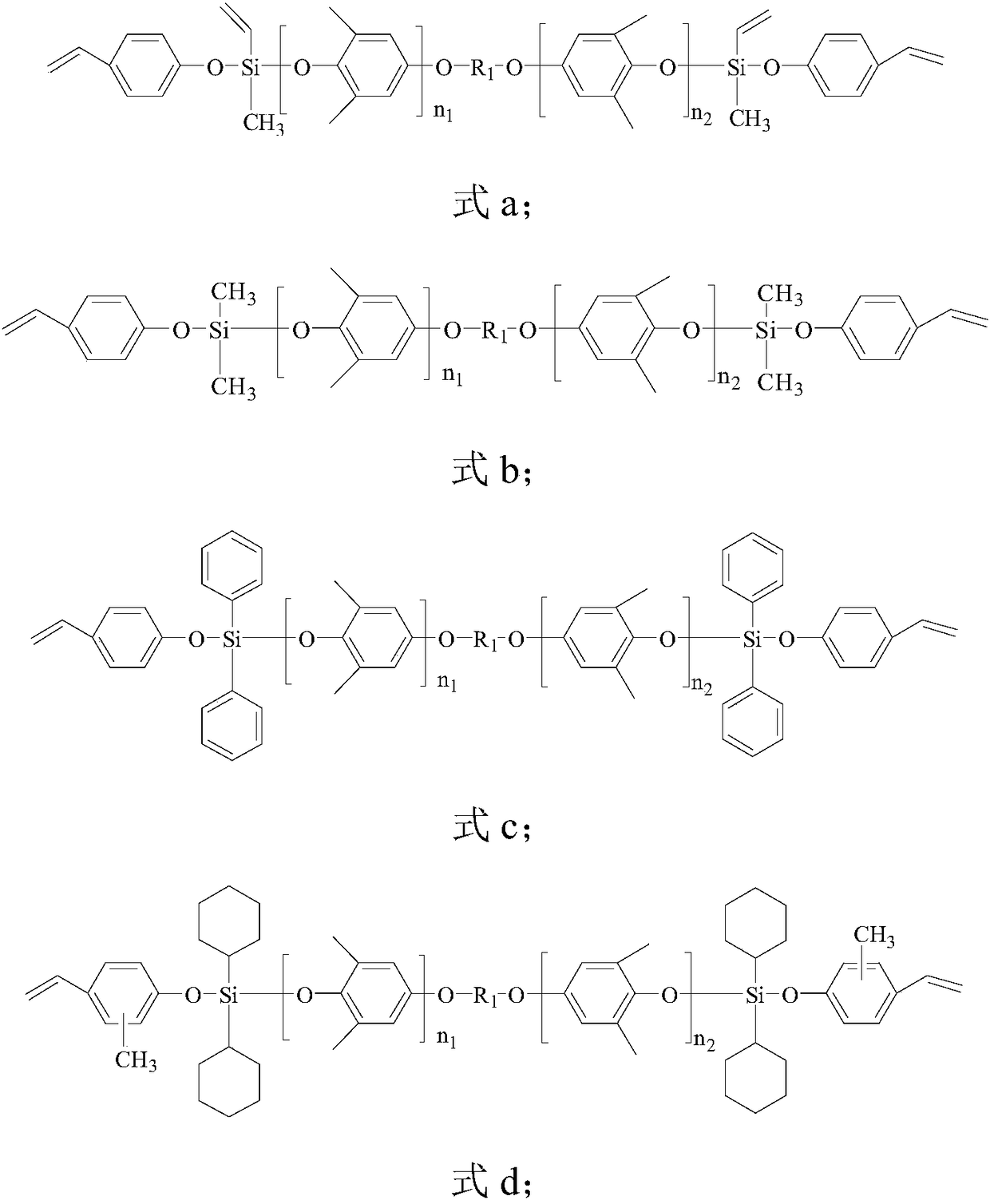

Styryl siloxy polyphenyl ether resin and preparation method and application thereof

A polyphenylene ether resin, styrene-based technology, applied in the field of styrene-based siloxy polyphenylene ether resin and its preparation, can solve the problems of undisclosed polyphenylene ether performance improvement and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

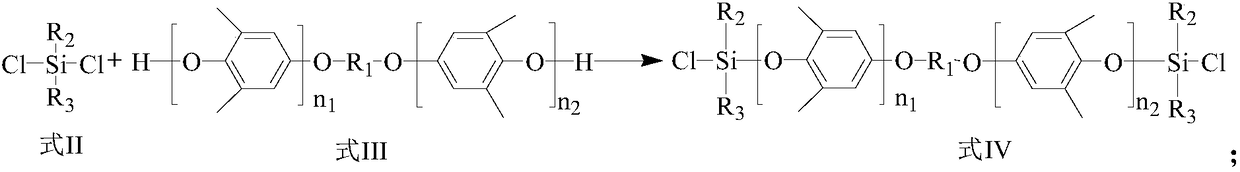

Method used

Image

Examples

Embodiment 1

[0094] Stir 73 parts by weight of polyphenylene ether resin MX90 and 1000 mL of anhydrous tetrahydrofuran in a reactor equipped with a stirrer, dropping funnel, thermometer, and gas pipe (nitrogen) until completely dissolved into a uniform solution, and continue to pass nitrogen 0.5- The water vapor in the reaction kettle was removed for 1 hour, and nitrogen gas was maintained throughout the reaction process. Keep the temperature in the reactor below 20°C, and then slowly add 19.5 parts by weight of diphenyldichlorosilane dropwise. After the addition is completed, the reaction kettle is kept below 20°C for 8 hours, and then the temperature is raised to 55°C for 3 hours. Subsequently, 7.5 parts by weight of p-hydroxystyrene was added dropwise to the reaction kettle, and reacted at 55° C. for 5 hours. After the reaction, the tetrahydrofuran was removed by distillation under reduced pressure to obtain a polyphenylene ether resin modified with a styryl siloxy group, which was desi...

Embodiment 2

[0096] Stir 80 parts by weight of polyphenylene ether resin MX90 and 1000 mL of anhydrous tetrahydrofuran in a reactor equipped with a stirrer, dropping funnel, thermometer and air duct (nitrogen) until completely dissolved into a uniform solution, and continue to pass nitrogen 0.5- The water vapor in the reaction kettle was removed for 1 hour, and nitrogen gas was maintained throughout the reaction process. At the same time, the temperature in the reactor is kept below 20°C, and then 12 parts by weight of methyl vinyl dichlorosilane are slowly added dropwise. After the addition is completed, the reaction kettle is kept below 20°C for 8 hours, and then the temperature is raised to 55°C for 3 hours. Subsequently, 8 parts by weight of p-hydroxystyrene was added dropwise to the reaction kettle, and reacted at 55° C. for 5 hours. After the completion of the reaction, tetrahydrofuran was removed by distillation under reduced pressure to obtain a polyphenylene ether resin modified w...

Embodiment 3

[0098] Stir 80 parts by weight of polyphenylene ether resin MX90 and 1000 mL of anhydrous tetrahydrofuran in a reactor equipped with a stirrer, dropping funnel, thermometer and air duct (nitrogen) until completely dissolved into a uniform solution, and continue to pass nitrogen 0.5- The water vapor in the reaction kettle was removed for 1 hour, and nitrogen gas was maintained throughout the reaction process. At the same time, the temperature in the reactor was kept below 20°C, and 11 parts by weight of dimethyldichlorosilane were slowly added dropwise. After the addition is completed, the reaction kettle is kept below 20°C for 9 hours, and then the temperature is raised to 50°C for 4 hours. Subsequently, 9 parts by weight of p-hydroxystyrene were added dropwise to the reaction kettle and reacted at 52°C for 6 hours. After the completion of the reaction, tetrahydrofuran was removed by distillation under reduced pressure to obtain a polyphenylene ether resin modified with a styr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com