A method for extracting limonin in lemon peel residue with guanidinium salt ionic liquid two-phase aqueous phase

A technology of ionic liquid and lemon peel, which is applied in the fields of steroids and organic chemistry, can solve the problems of difficult development and utilization of lemon pomace, slow browning of juice yield, waste of resources, etc., and achieve a simple and feasible extraction method , broad commercial application prospects, the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

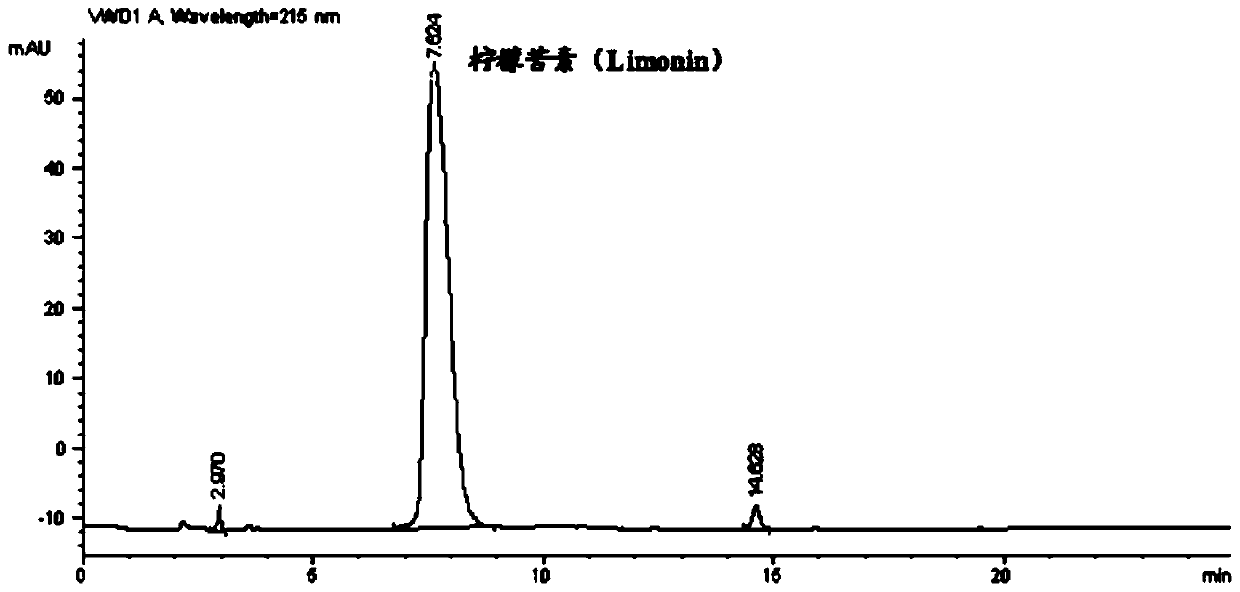

Image

Examples

Embodiment 1

[0030] Randomly purchased lemon juice waste from a lemon processing enterprise—lemon peel pomace as raw material, with a water content of (88.8±3.17)%. The following methods were used to prepare limonin:

[0031] (1) Drying and pulverizing of lemon zest: heating lemon zest at 40-45° C. to dry moisture, and the heating time is until the moisture content of lemon zest drops to 20%. Subsequently, grind and pulverize the dried skin dregs with a pulverizer, and filter through a filter equipped with a 100-120 mesh screen for subsequent use.

[0032] (2) Enzymolysis: preparation of solid compound enzyme, solid lysozyme, solid cellulase, solid 6-phosphogluconolactonase, solid papain, solid citrate lyase and solid ketose diphosphate with a purity of more than 99% The lyase is mixed according to the mass ratio of 0.5:1.5:3:4:0.5:0.5, and dissolved with 200 times the mass of sterile distilled water.

[0033]Add the lemon zest powder screened in the step (1) to an ethanol solution with a...

Embodiment 2

[0041] Randomly purchased lemon juice waste from a lemon processing enterprise—lemon peel pomace as raw material, with a water content of (88.8±3.17)%. The following methods were used to prepare limonin:

[0042] (1) Drying and pulverizing of lemon zest: heating lemon zest at 40-45° C. to dry moisture, and the heating time is until the moisture content of lemon zest drops to 20%. Subsequently, grind and pulverize the dried skin dregs with a pulverizer, and filter through a filter equipped with a 100-120 mesh screen for subsequent use.

[0043] (2) Enzymolysis: preparation of solid compound enzyme, solid lysozyme, solid cellulase, solid 6-phosphogluconolactonase, solid papain, solid citrate lyase and solid ketose diphosphate with a purity of more than 99% The lyase is mixed according to the mass ratio of 0.5:1.5:3:4:0.5:0.5, and dissolved with 200 times the mass of sterile distilled water.

[0044] Add the lemon zest powder screened in the step (1) to an ethanol solution with ...

Embodiment 3

[0052] Randomly purchased lemon juice waste from a lemon processing enterprise—lemon peel pomace as raw material, with a water content of (88.8±3.17)%. The following methods were used to prepare limonin:

[0053] (1) Drying and pulverizing of lemon zest: heating lemon zest at 40-45° C. to dry moisture, and the heating time is until the moisture content of lemon zest drops to 20%. Subsequently, grind and pulverize the dried skin dregs with a pulverizer, and filter through a filter equipped with a 100-120 mesh screen for subsequent use.

[0054] (2) Enzymolysis: preparation of solid compound enzyme, solid lysozyme, solid cellulase, solid 6-phosphogluconolactonase, solid papain, solid citrate lyase and solid ketose diphosphate with a purity of more than 99% The lyase is mixed according to the mass ratio of 0.5:1.5:3:4:0.5:0.5, and dissolved with 200 times the mass of sterile distilled water.

[0055] Add the lemon zest powder screened in the step (1) to an ethanol solution with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com