Internal heating evaporation boat with composite ceramic coating and preparation method thereof

A composite ceramic and internal heating technology, which is applied in coating, vacuum evaporation plating, metal material coating process, etc., can solve the problems of becoming brittle, easy to break, and lower melting point, and achieve low porosity, tight bonding, and reduced The effect of manufacturing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

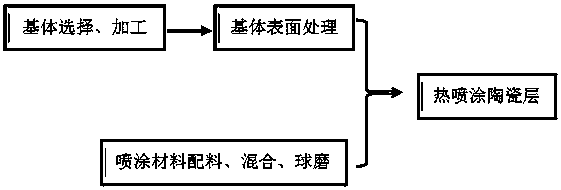

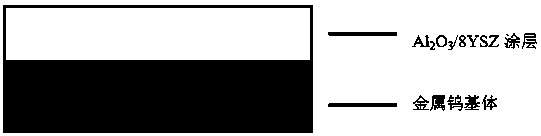

[0028] Preparation of Al by an Atmospheric Plasma Spraying Technology 2 o 3 -8YSZ adopts plasma spraying corrosion-resistant coating, including the following steps:

[0029] (1) Machining: Use high-purity tungsten to make a square tungsten boat with a thickness of 1mm and a length of 10cm as the base material ( figure 2 );

[0030] (2) Substrate surface treatment: Electrolytic corrosion polishing is carried out on the machined tungsten boat, then rough grinding is carried out with silicon carbide sandpaper, and then the surface coating treatment is carried out on the non-sprayed parts, and finally sandblasting is carried out for roughening. Enhance the mechanical bond between the spray powder and the substrate.

[0031] The electrolytic polishing mainly uses 3wt% sodium hydroxide aqueous solution, and the voltage is 6v to polish for 10 minutes. The sandblasting mainly adopts the GP-1 dry sandblasting machine produced by Beijing Changkong Sandblasting Equipment Co., Ltd., an...

Embodiment 2

[0037] Preparation of Al by an Atmospheric Plasma Spraying Technology 2 o 3 -8YSZ adopts plasma spraying corrosion-resistant coating, including the following steps:

[0038] (1) Machining: Use high-purity tungsten to make a square tungsten boat with a thickness of 1mm and a length of 10cm as the base material ( figure 2 );

[0039] (2) Substrate surface treatment: Electrolytic corrosion polishing is carried out on the machined tungsten boat, then rough grinding is carried out with silicon carbide sandpaper, and then the surface coating treatment is carried out on the non-sprayed parts, and finally sandblasting is carried out for roughening. Enhance the mechanical bond between the spray powder and the substrate.

[0040] The electrolytic polishing mainly uses 3wt% sodium hydroxide aqueous solution, and the voltage is 6v to polish for 10 minutes. The sandblasting mainly adopts the GP-1 dry sandblasting machine produced by Beijing Changkong Sandblasting Equipment Co., Ltd., an...

Embodiment 3

[0046] Preparation of Al by an Atmospheric Plasma Spraying Technology 2 o 3 -8YSZ adopts plasma spraying corrosion-resistant coating, including the following steps:

[0047] (1) Machining: Use high-purity tungsten to make a square tungsten boat with a thickness of 1mm and a length of 10cm as the base material ( figure 2 );

[0048] (2) Substrate surface treatment: Electrolytic corrosion polishing is carried out on the machined tungsten boat, then rough grinding is carried out with silicon carbide sandpaper, and then the surface coating treatment is carried out on the non-sprayed parts, and finally sandblasting is carried out for roughening. Enhance the mechanical bond between the spray powder and the substrate.

[0049] The electrolytic polishing mainly uses 3wt% sodium hydroxide aqueous solution, and the voltage is 6v to polish for 10 minutes. The sandblasting mainly adopts the GP-1 dry sandblasting machine produced by Beijing Changkong Sandblasting Equipment Co., Ltd., an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com