Polyimide aerogel with crosslinked surface functionalized nanoparticles and preparation method thereof

A nanoparticle, surface functional technology, applied in the field of airgel and its preparation, to achieve the effects of good heat resistance, stable physical and chemical properties, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

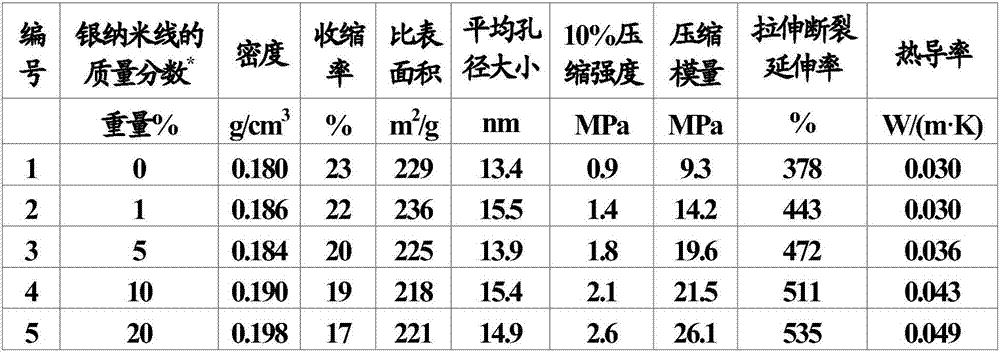

Embodiment 1

[0044] The preparation of polyimide airgel cross-linked by aminated silver nanowires: disperse the silver nanowires in absolute ethanol solvent, add p-mercaptoaniline with a molar ratio of 4:1 to the silver in the silver wires, Carry out amination modification in ethanol solvent for 6h, then centrifuge, wash 5 times with absolute ethanol and dry for later use; dissolve 15mmol of diamine monomer 4,4-diaminodiphenyl ether in solvent N,N-dimethyl Add 15.3 mmol of dianhydride monomer 3,3',4,4'-biphenyltetracarboxylic dianhydride slowly to acetamide, fully dissolve and react at room temperature for 4 hours to obtain an anhydride-terminated polyamide with a degree of polymerization of about 50 acid, and adjust the solid content to 12% by changing the quality of the solvent. A certain amount of modified silver nanowires is added to the polyamic acid solution. Crosslink for 40 min at room temperature with mechanical stirring. Then add triethylamine and acetic anhydride with a molar ...

Embodiment 2

[0052] Preparation of functionalized mesoporous silica cross-linked polyimide airgel: prepare mesoporous silica microspheres by template method, under rapid magnetic stirring, mix 2.31ml dodecylamine, 0.1822g hexadecane Trimethylammonium bromide was added to the mixed solution of ethanol, isopropanol, deionized water and a small amount of ammonia water (ethanol: 131.01ml, ammonia water: 0.11ml, isopropanol 47.74ml, deionized water 67.5ml), and then Add tetraethyl orthosilicate quickly, keeping stirring slowly. 10 hours after the addition, the reaction solution was centrifuged and ultrasonically dispersed, washed with deionized water, and repeated 5 times to obtain a wet powder of silica microspheres, and then the powder was freeze-dried for 3 hours. Finally, the dried powder was calcined in a high-temperature furnace at 700K for 10 h to obtain mesoporous silica microspheres. Subsequently, the microspheres and aminopropyltriethoxysilane were refluxed at 110° C. for 5 h in a to...

Embodiment 3

[0054] Preparation of isocyanate-modified graphene oxide cross-linked polyimide airgel: ultrasonically disperse graphene oxide in N-methylpyrrolidone, and add it in a ratio of 6:1 to graphene oxide mass ratio Diphenylmethane diisocyanate. React at 40°C for 24 hours under a nitrogen atmosphere, replace the hydroxyl and carboxyl groups on the graphene oxide with isocyanate groups, and purify by centrifugation, washing and dialysis to obtain isocyanate group-modified graphene oxide. According to the same procedure as in Example 1, the graphene oxide modified by the isocyanate group was added to the same polyamic acid solution as in Example 1 at a mass fraction of 5% based on the polyamic acid precursor, according to Example 1 The procedure in is carried out cross-linking reaction, gelation and chemical imidization reaction, and finally polyimide airgel is obtained by supercritical drying. The compressive modulus of the obtained product airgel is 40% higher than that of the sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com