Method of preparing MIM418 alloy through low-oxygen content mother alloy method

A low oxygen content, master alloy technology, applied in the field of powder metallurgy, can solve problems affecting product performance, achieve the effects of reducing sintering deformation, inhibiting volatilization, and ensuring element content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

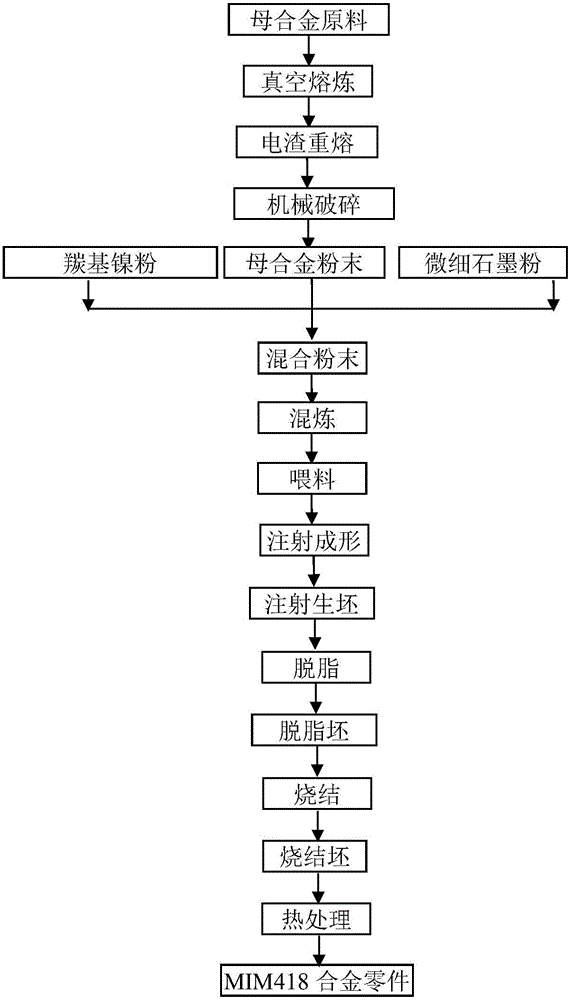

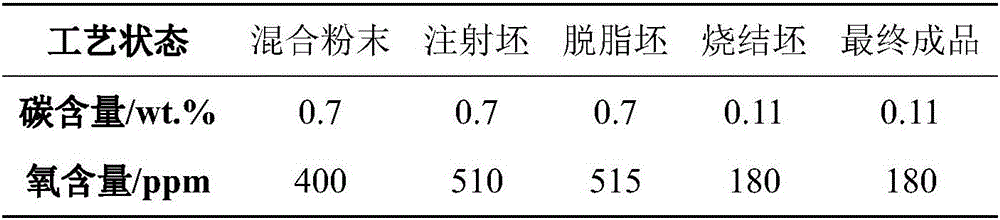

Method used

Image

Examples

Embodiment 1

[0022] The Ni-50wt.% Cr master alloy, Ni-5wt.% B master alloy, Ni-Mo master alloy, Ni-Nb master alloy with a purity greater than 99.9%, as well as aluminum blocks, sponge titanium, and sponge zirconium, at 5vol.% Pretreatment is carried out in hydrochloric acid aqueous solution to remove surface oxides. The pretreatment time is 30 minutes. After washing with alcohol, it is dried in an oven at 60°C for 60 minutes. 9.15Al-19.23Cr-6.62Mo-3.31Nb-1.15Ti-0.15Zr-0.02B-0.18C. The raw materials were smelted in a vacuum induction melting furnace. During the smelting process, a ceramic crucible was used, and the power was increased after the furnace material was melted, so that the temperature of the molten pool rose to 1670°C, and then 2wt.% carbon block was added and kept for 30 minutes. During the process, use an electromagnetic stirrer to stir the molten pool to fully remove oxygen, then add 1wt.% Al and Ti and 0.01wt.% B, keep it warm for 10 minutes, then cool down, fill with argon,...

Embodiment 2

[0024] The Ni-50wt.% Cr master alloy, Ni-5wt.% B master alloy, Ni-Mo master alloy, Ni-Nb master alloy with a purity greater than 99.9%, as well as aluminum blocks, sponge titanium, and sponge zirconium, at 5vol.% Pretreatment is carried out in hydrochloric acid aqueous solution to remove surface oxides. The pretreatment time is 30 minutes. After washing with alcohol, it is dried in an oven at 60°C for 60 minutes. 9.15Al-19.23Cr-6.62Mo-3.31Nb-1.15Ti-0.15Zr-0.02B-0.18C. The raw materials were smelted in a vacuum induction melting furnace. During the smelting process, a ceramic crucible was used, and the power was increased after the furnace material was melted, so that the temperature of the molten pool rose to 1670°C, and then 2wt.% carbon block was added and kept for 30 minutes. During the process, use an electromagnetic stirrer to stir the molten pool to fully remove oxygen, then add 1wt.% Al and Ti and 0.01wt.% B, keep it warm for 10 minutes, then cool down, fill with argon,...

Embodiment 3

[0026] The Ni-50wt.% Cr master alloy, Ni-5wt.% B master alloy, Ni-Mo master alloy, Ni-Nb master alloy with a purity greater than 99.9%, as well as aluminum blocks, sponge titanium, and sponge zirconium, at 5vol.% Pretreatment is carried out in hydrochloric acid aqueous solution to remove surface oxides. The pretreatment time is 30 minutes. After washing with alcohol, it is dried in an oven at 60°C for 60 minutes. 9.15Al-19.23Cr-6.62Mo-3.31Nb-1.15Ti-0.15Zr-0.02B-0.18C. The raw materials were smelted in a vacuum induction melting furnace. During the smelting process, a ceramic crucible was used, and the power was increased after the furnace material was melted, so that the temperature of the molten pool rose to 1670°C, and then 2wt.% carbon block was added and kept for 30 minutes. During the process, use an electromagnetic stirrer to stir the molten pool to fully remove oxygen, then add 1wt.% Al and Ti and 0.01wt.% B, keep it warm for 10 minutes, then cool down, fill with argon,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com