Preparation method and product of medical porous titanium-tantalum artificial bone and artificial joint

A technology for artificial joints and artificial bones, which is applied in the field of artificial joints and porous titanium-tantalum artificial bones for medical implants. It can solve problems such as difficult tantalum coating, aseptic loosening, and long time consumption, and achieve stable and reliable process and precise pore size. Controllable, guaranteed combined quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

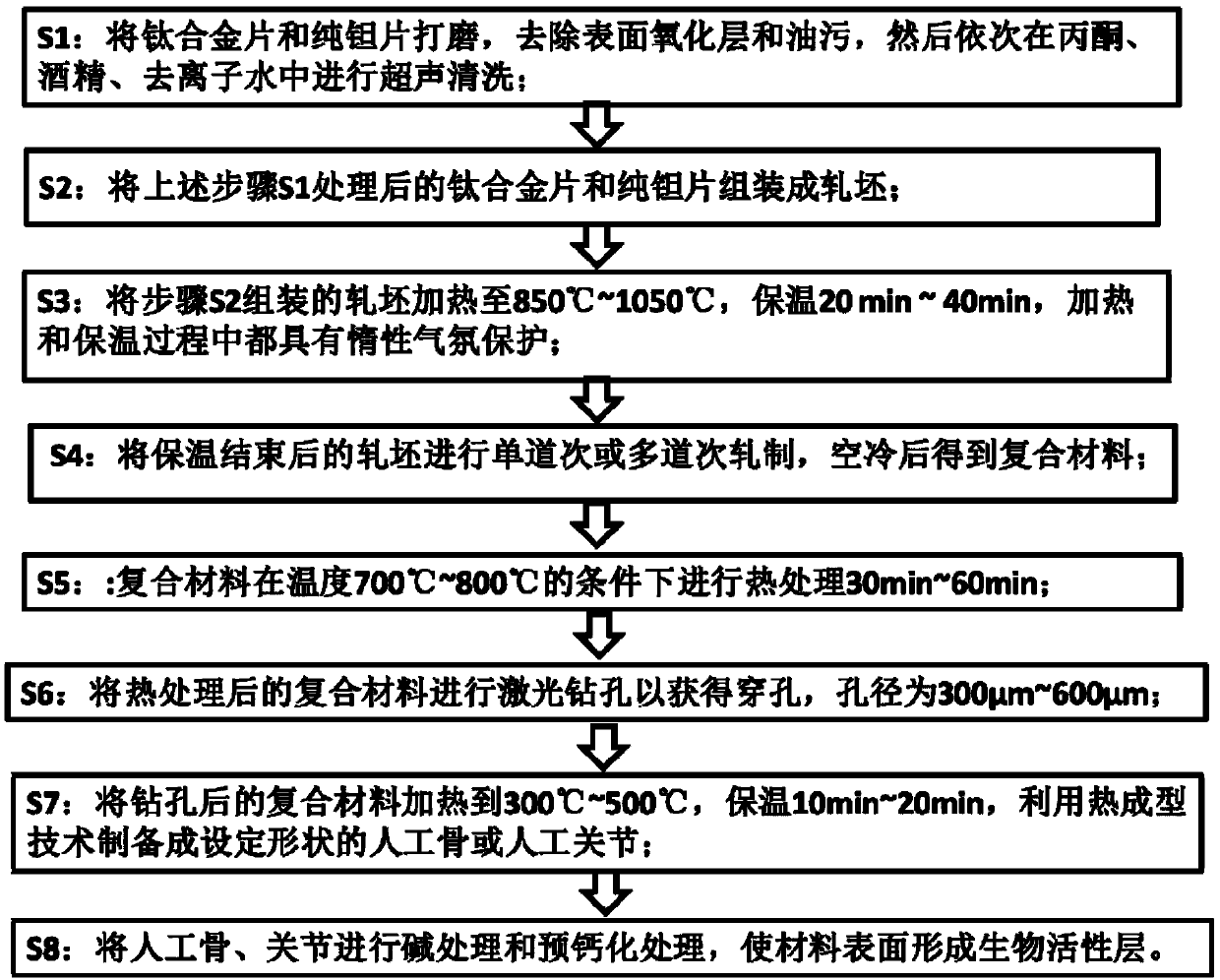

[0044] The preparation method of the invention is used to prepare a highly biocompatible medical metal implant porous titanium tantalum artificial bone and artificial joint. figure 1 It is a flow chart of the preparation method of the present invention, as can be seen from the figure, the inventive method comprises the steps:

[0045] S1: Grind TC4 titanium alloy sheet and pure tantalum sheet step by step with 400 mesh to 1200 mesh sandpaper to remove surface oxide layer and oil stain, and then perform ultrasonic cleaning in acetone, alcohol, and deionized water in sequence;

[0046] S2: Assemble the titanium alloy sheet and the pure tantalum sheet processed in the above step S1 into a billet; the assembly method is: attach the titanium alloy sheet and the pure tantalum sheet, and then use a precision welding machine to spot the side joints. welding fixed;

[0047] S3: heat up the slab assembled in step S2 to 850°C-1050°C, keep it warm for 20-40 minutes, and inert atmosphere ...

Embodiment 1

[0056] This embodiment includes the following steps:

[0057] S1: The titanium alloy sheet and the pure tantalum sheet are successively polished with 400-mesh, 800-mesh, and 1200-mesh sandpaper to remove the surface oxide layer and oil stains, and then ultrasonically cleaned in acetone, alcohol, and deionized water. Titanium alloy sheet is TC4 titanium alloy sheet, TC4 is the grade of titanium alloy, its specific composition is: iron (Fe)≤0.30, carbon (C)≤0.10, nitrogen (N)≤0.05, hydrogen (H)≤0.015, oxygen (O)≤0.20, aluminum (Al) 5.5~6.8, vanadium (V) 3.5~4.5, the balance is titanium (Ti);

[0058] S2: Assemble the titanium alloy sheet and pure tantalum sheet processed in the above step S1 into a rolled billet. The assembly method is: bonding the titanium alloy sheet and pure tantalum sheet, and then using argon tungsten arc welding precision welding repair machine Spot welding at the side joint;

[0059] S3: Heating the slab assembled in step S2 to 850°C and holding it for ...

Embodiment 2

[0069] This embodiment includes the following steps:

[0070] S1: The titanium alloy sheet and the pure tantalum sheet are successively polished with 400-mesh, 800-mesh, and 1200-mesh sandpaper to remove the surface oxide layer and oil stains, and then ultrasonically cleaned in acetone, alcohol, and deionized water. The titanium alloy sheet is TC4 titanium alloy sheet;

[0071] S2: Assemble the titanium alloy sheet and pure tantalum sheet processed in the above step S1 into a rolled billet. The assembly method is: bonding the titanium alloy sheet and pure tantalum sheet, and then using argon tungsten arc welding precision welding repair machine Spot welding at the side joint;

[0072] S3: Heating the slab assembled in step S2 to 1050°C and holding it for 20 minutes, with an inert atmosphere protection during the heating and holding process, and the heating rate is 120°C / min;

[0073] S4: Carry out single-pass or multi-pass rolling on the slab after the heat preservation in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com