Bi-component solvent-free reactive polyurethane hot melt adhesive applied in electronics and household appliance industry and using method thereof

A polyurethane hot-melt adhesive, two-component technology, used in polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve the problem of long PUR curing time, low Young's modulus, slow bonding strength, etc. problems, to ensure the quality of bonding, increase high temperature resistance, improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

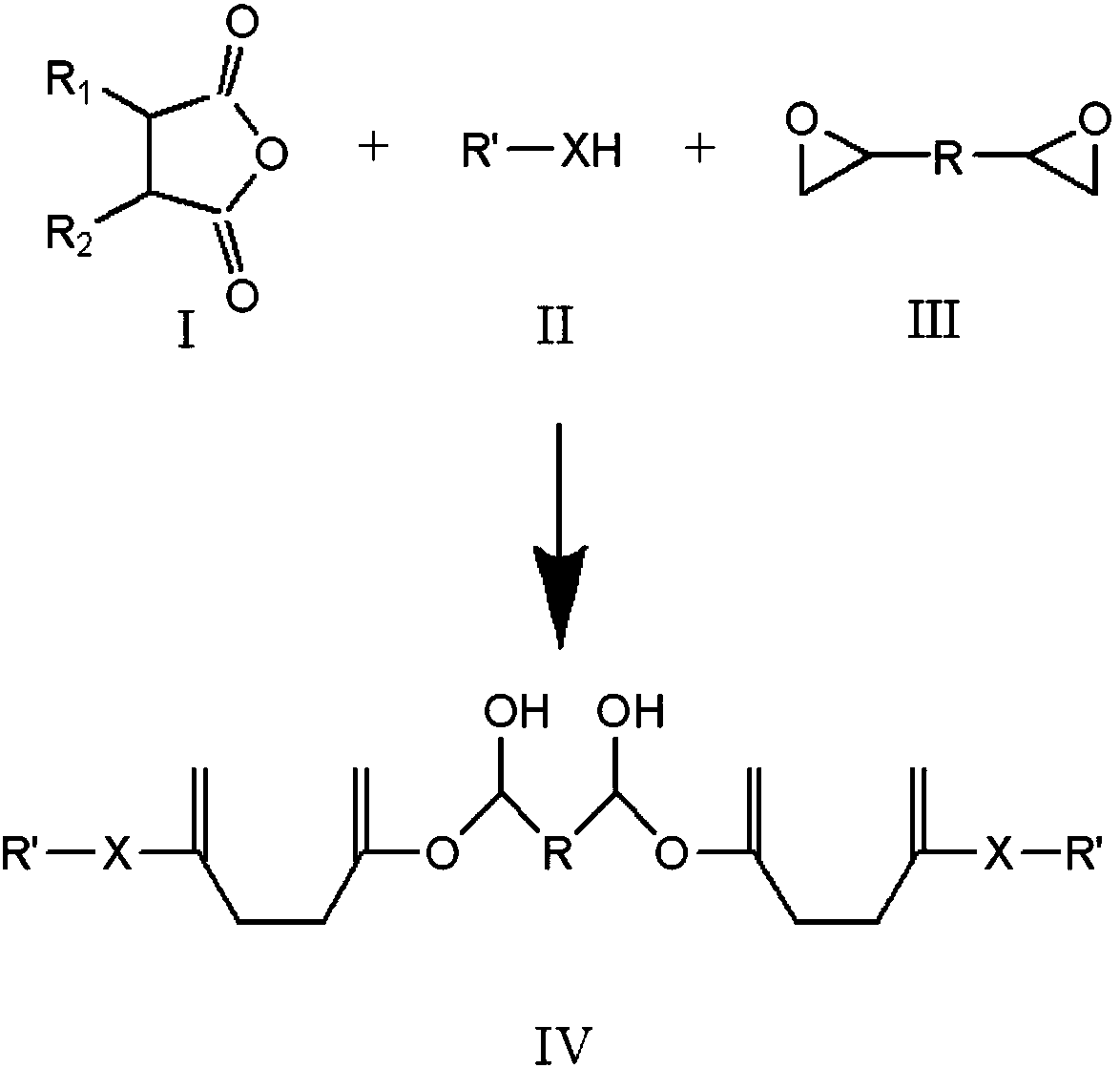

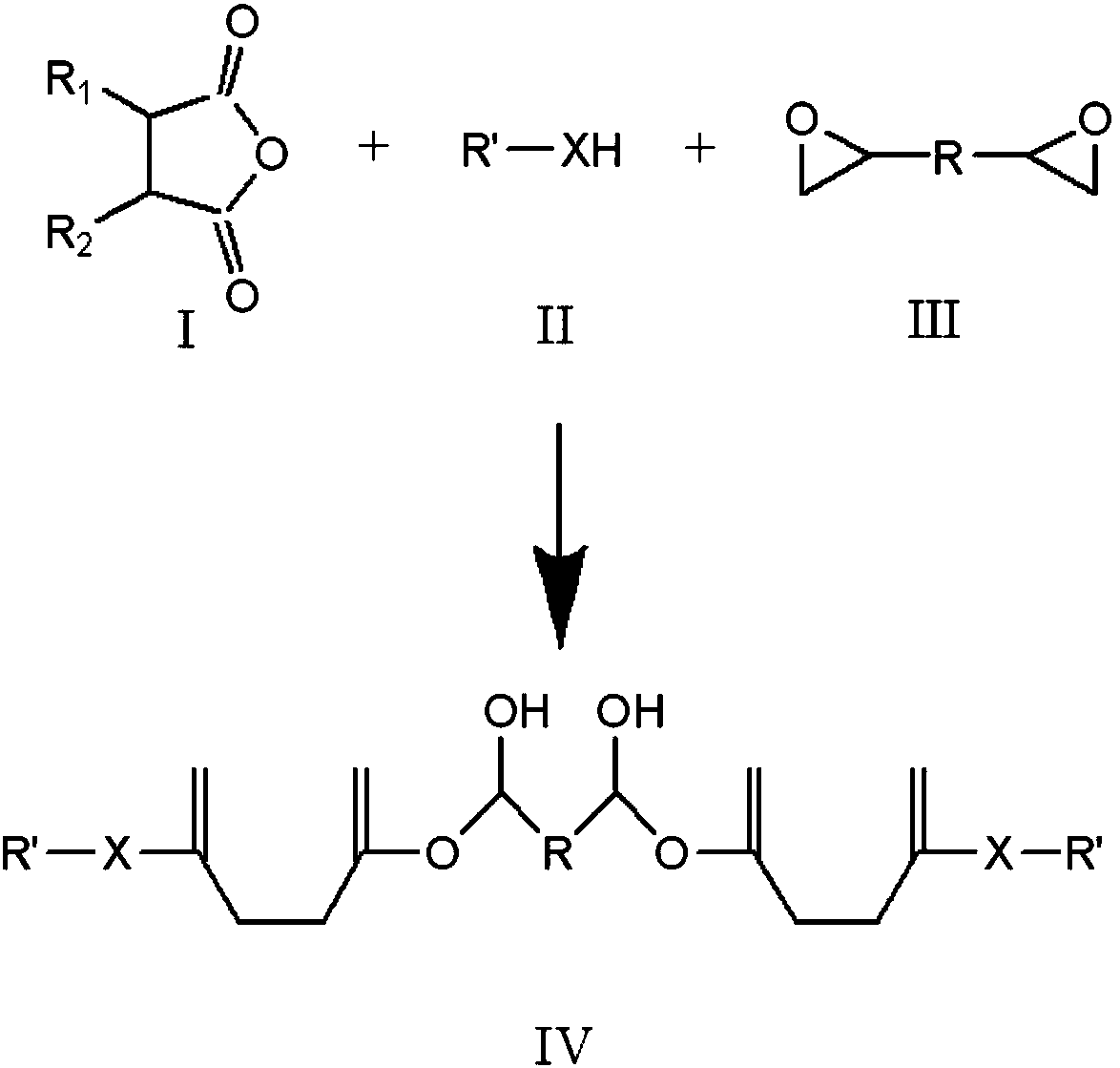

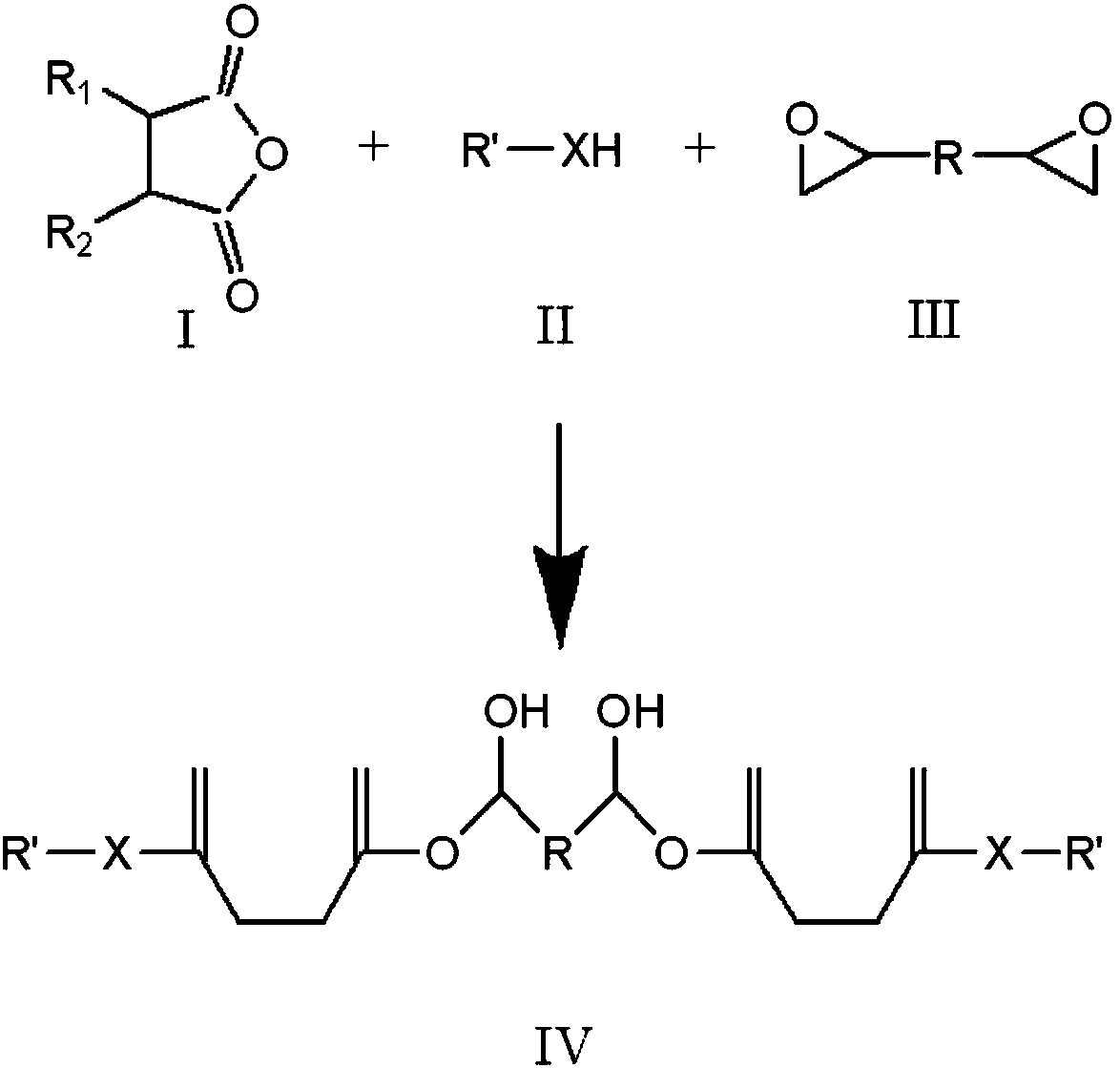

Method used

Image

Examples

Embodiment 1

[0031] A two-component solvent-free reactive polyurethane hot melt adhesive described in Example 1 of the present invention, which is applied to the electronic home appliance industry, includes component A and component B:

[0032] ——The component A includes a prepolymer with isocyanate groups in the side chain, an auxiliary agent, and a first catalyst; wherein the prepolymer has a functionality greater than or equal to 1, and its isocyanate content is 20%;

[0033] The prepolymer in the described component A is polyisocyanate and polyhydroxy compound b polymerization generation, wherein polyisocyanate is isophorone diisocyanate (IPDI) and diphenylmethane diisocyanate (MDI) in proportion (IPDI: MDI=0.6), and accounts for 60% of the total mass of component A; the polyhydroxy compound b is polyether polyol, selected Risheng Chemical Co., Ltd. P-2707 polyester polyol hydroxyl value range It is 150-180 mgKOH / g, and its molecular weight is 700 Daltons; wherein the polyhydroxy compo...

Embodiment 2

[0048] The present invention described in Embodiment 2 of the present invention also relates to a method for using a two-component solvent-free reactive polyurethane hot melt adhesive for the plastic film industry, including the following steps:

[0049] (1) Before use, component A and component B are packaged in independent aluminum foil composite film airtight containers;

[0050] (2) In the process of use, put A component and B group into the melter and heat them to 100°C to melt, and output them to the static mixing tube in proportion (100:50) through the metering pump to mix or mechanically mix the two components. Mix evenly to obtain the two-component solvent-free reactive polyurethane glue.

[0051] (3) Preheat the glue-coated substrate at 50°C.

[0052] (4) After heating the uniformly mixed polyurethane glue to 100°C, glue the surface of the substrate by spraying, roller coating, flow coating, extrusion coating, etc.

[0053] (5) Lay another substrate to be bonded wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com