A kind of three-dimensional graphene bifunctional oxygen electrode catalyst and preparation method thereof

A graphene, bifunctional technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of poor stability, limited application range, slow kinetics, etc., and achieve good electrical conductivity and Mechanical properties, improved electrochemical performance, and the effect of increasing active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The present invention also provides a method for preparing the three-dimensional graphene bifunctional oxygen electrode catalyst described in the above technical solution, comprising the following steps:

[0060] (1) mixing graphite oxide, cobalt precursor, aluminum precursor, nitrogen precursor, templating agent and alkaline regulator to obtain a mixed solution;

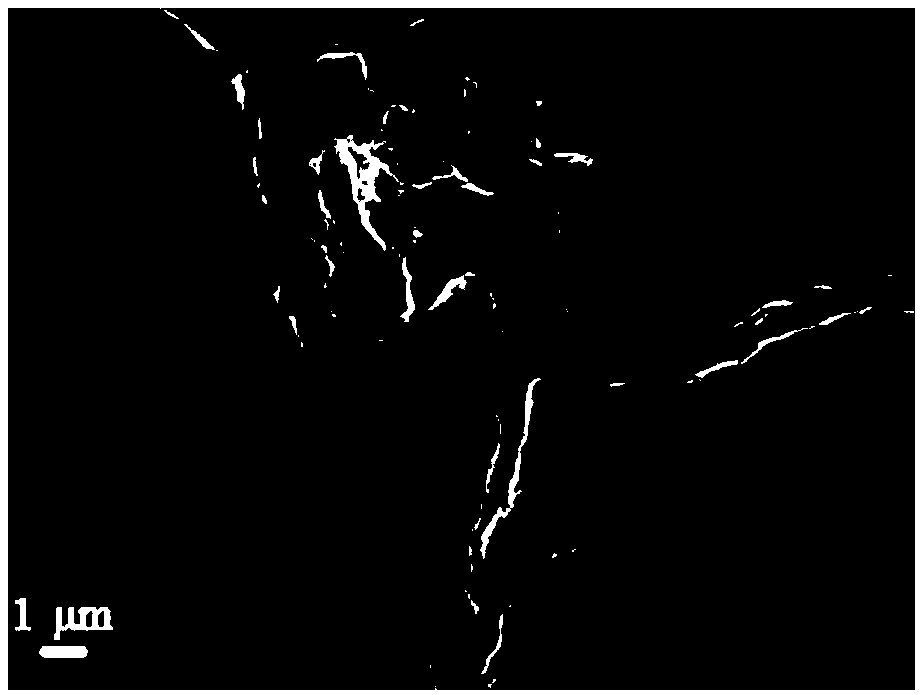

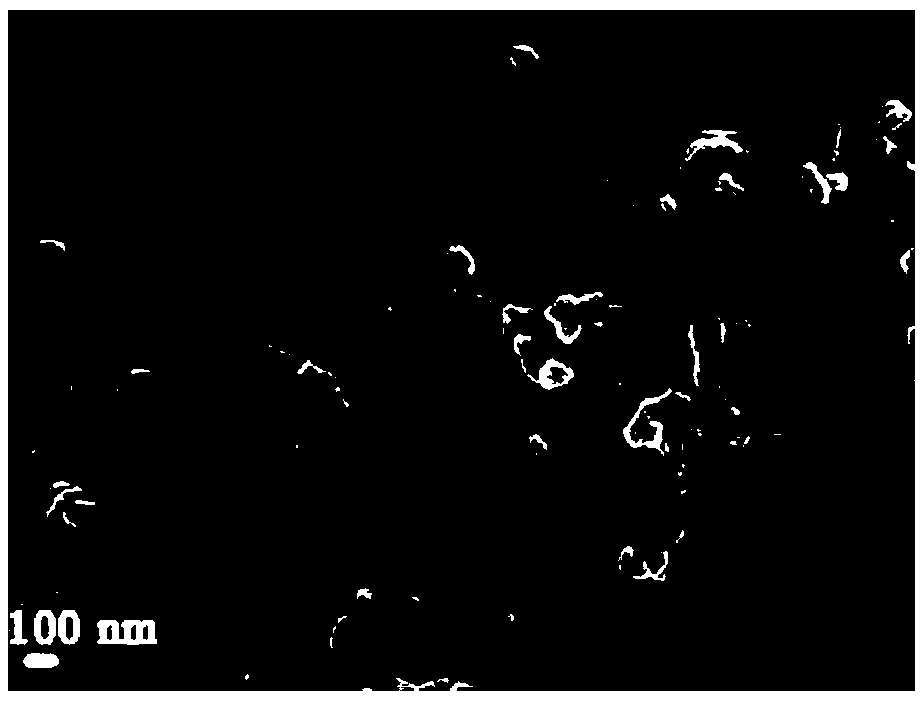

[0061] (2) carry out hydrothermal reaction to the mixed solution that described step (1) obtains, obtain the three-dimensional graphene hydrogel of cobalt-heteroatom tailoring;

[0062] (3) washing and drying the three-dimensional graphene hydrogel that described step (2) obtains, obtains three-dimensional graphene aerogel;

[0063] (4) calcining the three-dimensional graphene airgel obtained in the step (3) to obtain a cobalt-heteroatom-tailored three-dimensional graphene bifunctional oxygen electrode catalyst.

[0064] The invention mixes graphite oxide, cobalt precursor, aluminum precursor, nitrogen precu...

Embodiment 1

[0087] Weigh 2 grams of graphite powder and 2 grams of sodium nitrate, add them to a 1-liter three-neck flask and stir, slowly add 169.28 mg of concentrated sulfuric acid and 12 grams of potassium permanganate in an ice-water bath . Transfer the three-neck flask to a constant temperature hot water bath at 35°C and stir for 1 hour, slowly add 160 mg of deionized water to the ice water bath, and transfer to a constant temperature water bath at 90°C to stir for 0.5 hours, then add 400 mg of deionized water and 17.76 mg of 30% hydrogen peroxide. After standing overnight, pour off the supernatant, filter with suction, dissolve the filter cake and put it into a dialysis bag for dialysis until the pH is 7.02, and then place it in an oven at 60°C to dry to obtain graphite oxide.

[0088] Disperse 55 mg of graphite oxide in 7 mg of deionized water, and ultrasonically disperse it uniformly to obtain a uniformly dispersed graphite oxide aqueous solution.

Embodiment 2

[0090] Weigh 495 mg of melamine, 325 mg of sodium chloride, and 32 mg of ethanol, and add them to 30 mg of the graphite oxide aqueous solution of Example 1 at the same time, heat and stir in a constant temperature water bath at 40°C for 6 hours, and then add 4.54 mg of Ammonia, adjust the pH value of the mixture to 12. The mixture was transferred to a reaction kettle and reacted in an oven at 180°C for 12 hours, then cooled to room temperature for 52 minutes at a cooling rate of 3°C / min to obtain a nitrogen-doped three-dimensional graphene hydrogel (3D NG) . The 3DNG hydrogel was washed with water to a pH of 7.04, and freeze-dried at a freezing rate of 0.02 Pa / (g m2) at −80 °C and a vacuum of 0.2 Pa to obtain a 3D NG aerogel. Place the airgel in the center of a vacuum quartz tube furnace under argon protection, and raise the temperature to 300°C at a heating rate of 5°C / min, and then raise the temperature to 800°C at a heating rate of 10°C / min and keep it for 2 hours After t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com