Track material for stadium

A technology for sports fields and runways, which is applied in the field of track materials for sports fields, can solve the problems of restricting the performance of plastic runways, and cannot completely improve the rebound rate, tensile strength and elongation at break of plastic runways, and achieve excellent flame retardant properties. , High rebound rate, the effect of improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

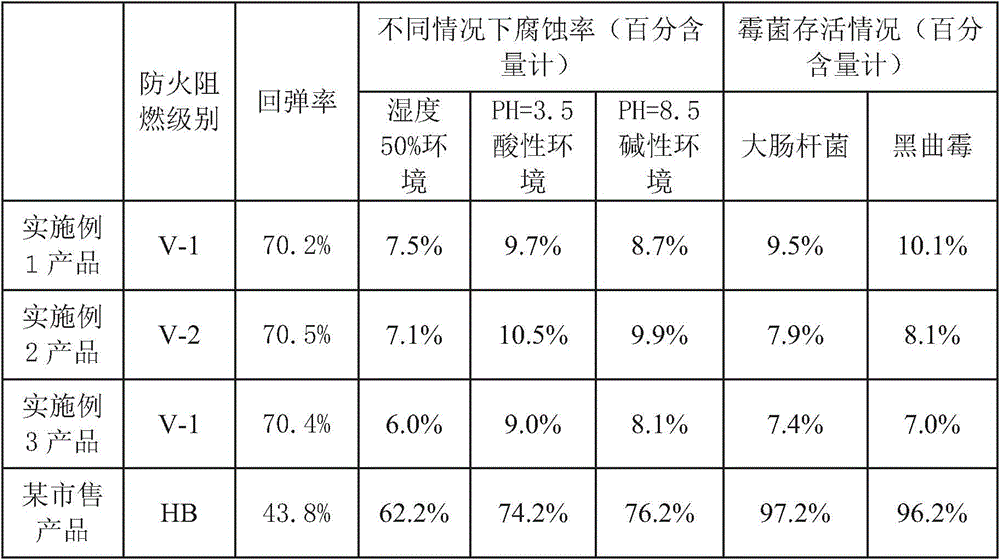

Examples

Embodiment 1

[0016] The track material for the sports field in this embodiment is composed of the following parts by mass: 12 parts of styrene-butadiene-styrene block copolymer, 14 parts of polyethylene wax, and 10 parts of decabromodiphenyl ether , 8 parts of garlic extract, 14 parts of coal ash, 10 parts of tourmaline powder, 8 parts of strontium chromate powder, 14 parts of seaweed iodized salt, 10 parts of magnesium methacrylate, 8 parts of sodium phosphate, 14 parts of magnesite powder, molybdenum 10 parts of zinc acid powder, 10 parts of nano carbon powder, 8 parts of nano calcium carbonate, 14 parts of nano alumina powder, 10 parts of diethylene glycol butyl ether, 8 parts of polyvinyl acetate emulsion, 14 parts of sulfenamide accelerators, single 10 parts of glyceryl stearate, 8 parts of p-aminophenol, 14 parts of terephthalic acid, 10 parts of fluoroalkyl polyether modified polysiloxane, 8 parts of glycerol monostearate, 14 parts of sodium citrate Parts, 10 parts of tert-butyl hydr...

Embodiment 2

[0022] The track material for the sports field in this embodiment is composed of the following parts by mass: 14 parts of styrene-butadiene-styrene block copolymer, 16 parts of polyethylene wax, and 12 parts of decabromodiphenyl ether , 10 parts garlic extract, 16 parts coal ash, 12 parts tourmaline powder, 10 parts strontium chromate powder, 16 parts seaweed iodized salt, 12 parts magnesium methacrylate, 10 parts sodium phosphate, 16 parts magnesite powder, molybdenum 12 parts of zinc acid powder, 12 parts of nano carbon powder, 10 parts of nano calcium carbonate, 16 parts of nano alumina powder, 12 parts of diethylene glycol butyl ether, 10 parts of polyvinyl acetate emulsion, 16 parts of sulfenamide accelerator, single 12 parts of glyceryl stearate, 10 parts of p-aminophenol, 16 parts of terephthalic acid, 12 parts of fluoroalkyl polyether modified polysiloxane, 10 parts of glycerol monostearate, 16 parts of sodium citrate Parts, 12 parts of tert-butyl hydrogen peroxide, 12 ...

Embodiment 3

[0028] The track material for the sports field in this embodiment is composed of the following parts by mass: 16 parts of styrene-butadiene-styrene block copolymer, 18 parts of polyethylene wax, and 14 parts of decabromodiphenyl ether , 12 parts garlic extract, 18 parts coal ash, 14 parts tourmaline powder, 12 parts strontium chromate powder, 18 parts seaweed iodized salt, 14 parts magnesium methacrylate, 12 parts sodium phosphate, 18 parts magnesite powder, molybdenum 14 parts of zinc acid powder, 14 parts of nano carbon powder, 12 parts of nano calcium carbonate, 18 parts of nano alumina powder, 14 parts of diethylene glycol butyl ether, 12 parts of polyvinyl acetate emulsion, 18 parts of sulfenamide accelerators, single 14 parts of glyceryl stearate, 12 parts of p-aminophenol, 18 parts of terephthalic acid, 14 parts of fluoroalkyl polyether modified polysiloxane, 12 parts of glycerol monostearate, 18 parts of sodium citrate Parts, 14 parts of tert-butyl hydrogen peroxide, 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com