Preparation method of carbon/carbon composite material surface reaction deposition metal tungsten skeleton coating

A carbon composite material and surface reaction technology, which is applied in the preparation field of carbon/carbon composite material surface reaction deposition metal tungsten skeleton coating, can solve the problems such as not suitable for W coating, achieve low cost, uniform pore size distribution, and good bonding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

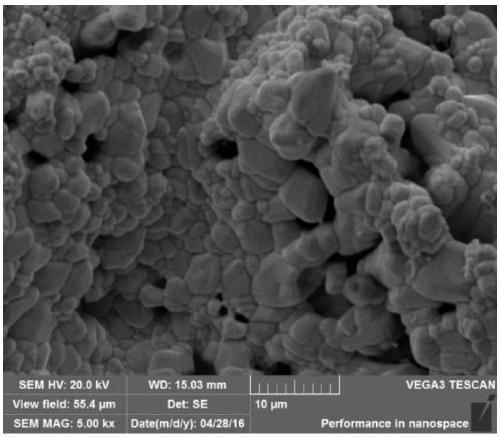

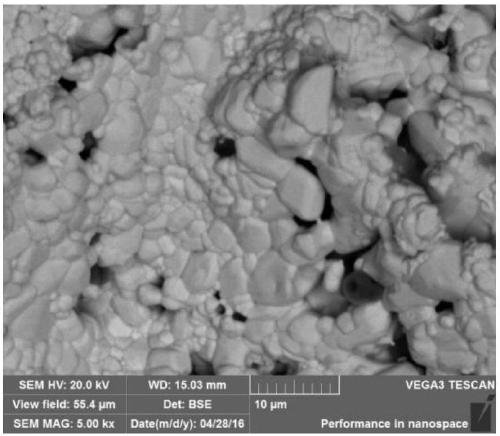

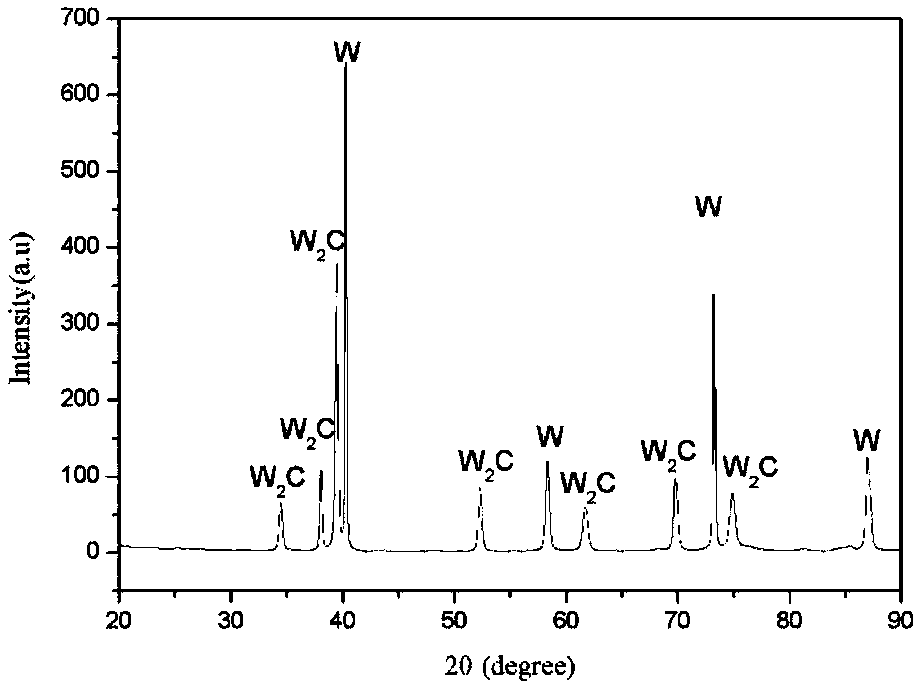

Image

Examples

Embodiment 1

[0022] 1) According to the specification of 10×10×10mm, the density is ρ=1.70g / cm 3 The C / C composite material is processed into a sample, polished with 80-grit sandpaper to roughen the surface, cleaned and dried;

[0023] 2) Buy Si powder, C powder, Al from the market 2 o 3 Mix the powder as raw material in a ratio of 5:1:0.5, and then put the mixed powder in a ball mixer and stir for 0.5h as the embedding powder. Put the C / C sample obtained in step 1 into a graphite crucible, and bury the above powder. Put the crucible into a high-temperature vacuum graphitization furnace and keep it at 1900°C for 2 hours under an argon protective atmosphere to obtain a C / C composite material sample with a certain thickness of SiC coating. Then use sandpaper to smooth the surface of the coating, clean and dry;

[0024] 3) Buy W powder from the market, Al 2 o 3 Powder, NH 4 F powder is used as raw material, first mix tungsten powder and NHF 4 powder according to the mass fraction of 8...

Embodiment 2

[0026] 1) According to the specification of φ10mm, the density is ρ=1.70g / cm 3 The C / C composite material is processed into a sample, polished with 80-grit sandpaper to roughen the surface, cleaned and dried;

[0027] 2) Buy Si powder, C powder, Al from the market 2 o 3 Mix the powder as raw material in a ratio of 5:1:0.5, and then put the mixed powder in a ball mixer and stir for 0.5h as the embedding powder. Put the C / C sample obtained in step 1 into a graphite crucible, and bury the above powder. Put the crucible into a high-temperature vacuum graphitization furnace and keep it warm at 2000°C for 2 hours under an argon protective atmosphere to obtain a C / C composite material sample with a certain thickness of SiC coating. Then use sandpaper to smooth the surface of the coating, clean and dry;

[0028] 3) Buy W powder from the market, Al 2 o 3 Powder, NH 4 F powder is used as raw material, first mix tungsten powder and NHF 4 Powder is mixed according to mass fraction...

Embodiment 3

[0030] 1) According to the specification of φ20×10mm, the density is ρ=1.70g / cm 3 The C / C composite material is processed into a sample, polished with 80-grit sandpaper to roughen the surface, cleaned and dried;

[0031] 2) Buy Si powder, C powder, Al from the market 2 o 3Mix the powder as raw material in a ratio of 5:1:0.5, and then put the mixed powder in a ball mixer and stir for 0.5h as the embedding powder. Put the C / C sample obtained in step 1 into a graphite crucible, and bury the above powder. Put the crucible into a high-temperature vacuum graphitization furnace under an argon protective atmosphere, and keep it at 2100°C for 2 hours to obtain a C / C composite material sample with a certain thickness of SiC coating. Then use sandpaper to smooth the surface of the coating, clean and dry;

[0032] 3) Buy W powder from the market, Al 2 o 3 Powder, NH 4 F powder is used as raw material, first mix tungsten powder and NHF 4 powder according to the mass fraction of 70%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com