Self-propagating synthesis method for submicron-grade TiB2 powder

A submicron-scale, synthetic method technology, applied in the direction of boron/boride, metal boride, etc., can solve the problems of high preparation cost, high cost of raw materials and equipment, and difficulty in controlling the purity of boron thermal reduction method, and achieve low production cost , high production efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

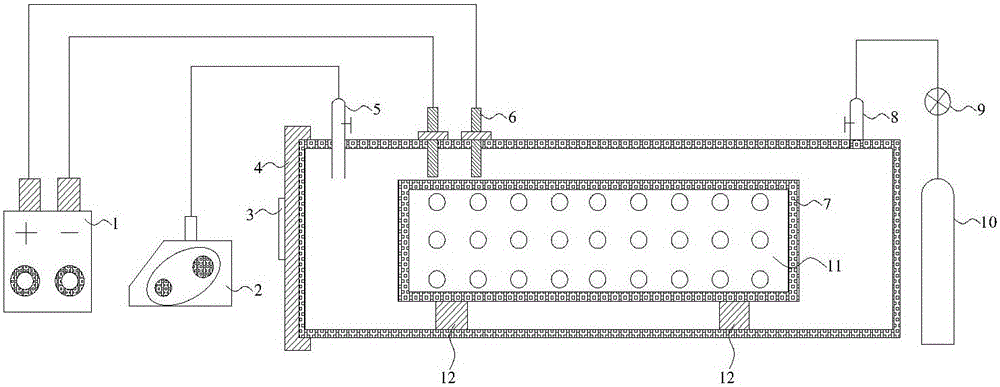

Method used

Image

Examples

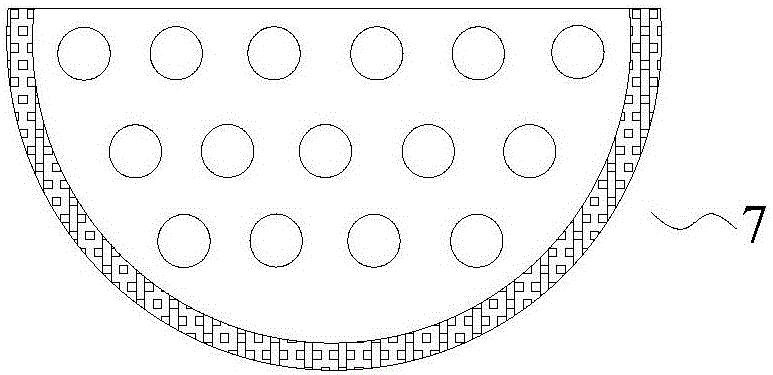

Embodiment 1

[0028] TiO 2 , B 2 o 3 and magnesium powder according to the mass ratio TiO 2 :B 2 o 3 :Mg=80:105:120 ingredients, namely B 2 o 3 Excessive 50%, metal magnesium excessive 5%. After preliminary mixing in the stainless steel barrel, put it into a drum mixer with alumina lining, add zirconia balls with a diameter of 10mm, zirconia balls and TiO 2 , B 2 o 3 The mass ratio to the sum of the total weight of the metal magnesium powder is 1:1, and the materials are mixed for 2 hours at a speed of 25 rpm, and the raw materials are mixed evenly. The material is pressed into a cylindrical green body with a diameter of 50 mm under a pressure of 5 MPa using a stainless steel mold. Put the pressed cylindrical green body into the graphite boat, insert the plug-in board, put the graphite boat into the self-propagating reaction chamber, and then pass the flowing Ar gas to protect the self-propagating reaction chamber after evacuating the self-propagating reaction chamber. After elec...

Embodiment 2

[0030] TiO 2 , B 2 o 3 and magnesium powder according to the mass ratio TiO 2 :B 2 o 3 :Mg=80:91:132 ingredients, ie B 2 o 3 Excessive 30%, metal magnesium excessive 10%. After preliminary mixing in the stainless steel barrel, put it into a drum mixer with alumina lining, add zirconia balls with a diameter of 10mm, zirconia balls and TiO 2 , B 2 o 3The mass ratio to the sum of the total weight of the metal magnesium powder is 1:1, and the materials are mixed for 2 hours at a speed of 25 rpm, and the raw materials are mixed evenly. The material is pressed into a cylindrical green body with a diameter of 50 mm under a pressure of 7 MPa using a stainless steel mold. Put the pressed cylindrical green body into the graphite boat, insert the plug-in plate, put the graphite boat into the self-propagating reaction chamber, and put the flowing Ar gas into the reaction chamber for protection after evacuating the reaction chamber. After electrification, the white-hot electric ...

Embodiment 3

[0032] TiO 2 , B 2 o 3 and magnesium powder according to the mass ratio TiO 2 :B 2 o 3 :Mg=80:105:132 ingredients, namely B 2 o 3 Excessive 50%, metal magnesium excessive 10%. After preliminary mixing in the stainless steel barrel, put it into a drum mixer with alumina lining, add zirconia balls with a diameter of 10mm, zirconia balls and TiO 2 , B 2 o 3 The mass ratio to the sum of the total weight of the metal magnesium powder is 1.5:1, and the raw materials are mixed evenly at a speed of 25 rpm for 2 hours. The material is pressed into a cylindrical green body with a diameter of 50 mm under a pressure of 10 MPa using a stainless steel mold. Put the pressed cylindrical green body into the graphite boat, insert the plug-in plate, put the graphite boat into the self-propagating reaction chamber, and put the flowing Ar gas into the reaction chamber for protection after evacuating the reaction chamber. After electrification, the white-hot electric heating wire ignites...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com