Method for preparing graphene toughened silicon carbide ceramic composite material

A technology of ceramic composite materials and tough silicon carbide, which is applied in the field of preparation of graphene toughened silicon carbide ceramic composite materials, can solve the problems of low interface bonding strength, reduced oxidation resistance, and poor material uniformity, so as to improve the interface strength And anti-oxidation ability, improve compactness and high temperature resistance, increase the effect of crack growth resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of graphene toughened silicon carbide ceramic composite material, comprising the steps of:

[0026] (1) Add graphene into alcohol aqueous solution and stir evenly, ultrasonically disperse for 0.5~5 hours, and prepare graphene dispersion with a concentration of 0.5g / L~5g / L;

[0027] (2) According to the mass ratio of ethyl orthosilicate and graphite oxide of 20:1~1:1, add ethyl orthosilicate to the graphite oxide solution, then add a small amount of reducing agent, and continue magnetic stirring for 0.5~5 hours, so that It is fully dissolved and mixed uniformly to obtain a mixed solution of graphite oxide / tetraethyl orthosilicate;

[0028] (3) Place the above-mentioned graphite oxide / tetraethyl orthosilicate mixed solution in a stainless steel reaction kettle, heat at 100-200°C, and perform a hydrothermal reduction reaction for 1-24 hours. After the reaction is completed, the product is suction-filtered, washed repeatedly with deionized water and ab...

Embodiment 1

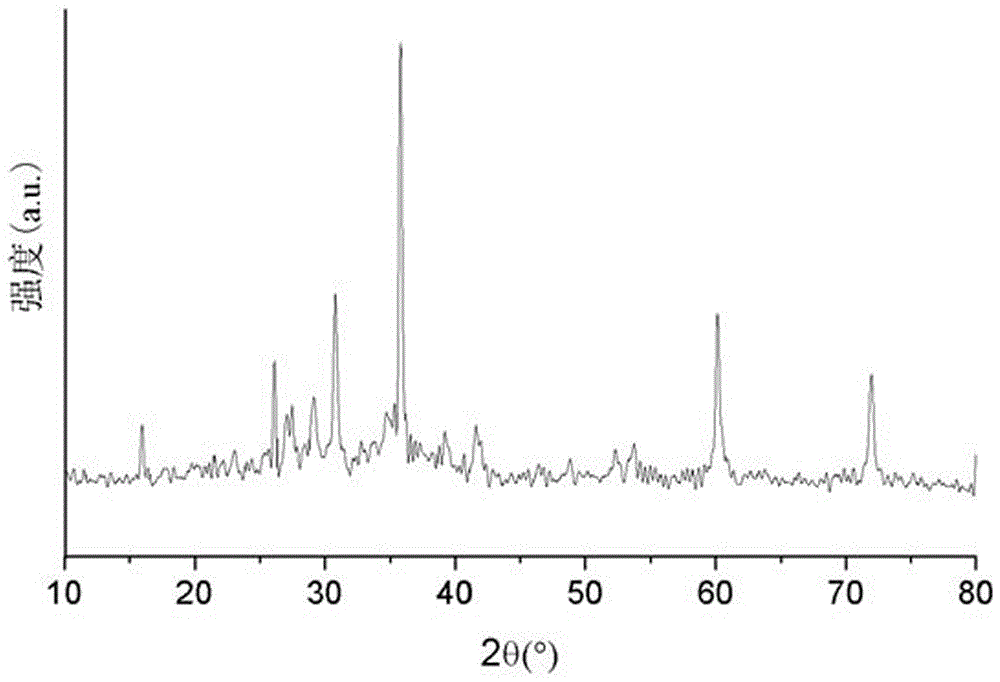

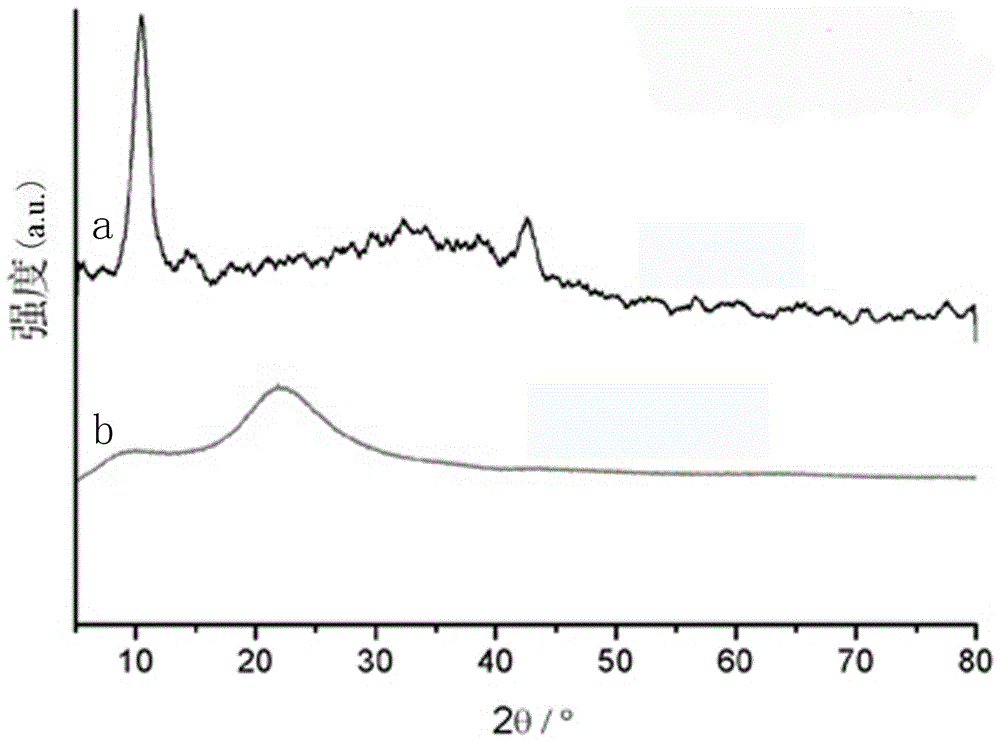

[0033] Weigh 20 mg of graphite oxide and add it to 40 mL of alcoholic water solution (the volume ratio of absolute ethanol and deionized water is 1:9), stir evenly, and ultrasonically disperse for 0.5 hours. The concentration of the prepared graphite oxide solution is 0.5 g / L. Then add 0.4 g of tetraethyl orthosilicate and 1 mL of reducing agent ammonia, wherein the mass ratio of tetraethyl orthosilicate to graphite oxide is 20:1, and continue magnetic stirring for 0.5 hours to fully dissolve and mix evenly. Place the graphite oxide / tetraethyl orthosilicate mixed solution in a stainless steel reaction kettle with a volume of 100mL, the volume ratio of the solution is 40%, and the heating temperature is 100 o C, hydrothermal reduction reaction for 1 hour. After the reaction was completed, the product was suction filtered, washed repeatedly with deionized water and absolute ethanol, and dried in vacuum at 50°C for 12 hours to obtain SiO 2 Wrapped graphene composite powder. The...

Embodiment 2

[0035] Weigh 180 mg of graphite oxide and add it to 60 mL of alcoholic water solution (the volume ratio of absolute ethanol and deionized water is 1:1), stir evenly, ultrasonically disperse for 3 hours, and the concentration of the prepared graphite oxide solution is 3 g / L. Then add 1.8 g of tetraethyl orthosilicate and 5 mL of reducing agent ammonia water, wherein the mass ratio of tetraethyl orthosilicate to graphite oxide is 10:1, and continue magnetic stirring for 3 hours to fully dissolve and mix evenly. The graphite oxide / tetraethyl orthosilicate mixed solution was placed in a stainless steel reaction kettle with a volume of 100mL, the volume ratio of the solution was 60%, the heating temperature was 150°C, and the hydrothermal reduction reaction was carried out for 12 hours. After the reaction was completed, the product was suction filtered, washed repeatedly with deionized water and absolute ethanol, and dried in vacuum at 80°C for 48 hours to obtain SiO 2 Wrapped grap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com