Preparing method for high-strength and large-specific-surface-area titanium black coating

A large specific surface area, high strength technology, applied in the surface field, can solve the problems of high mechanical strength, high equipment requirements, poor friction resistance, etc., and achieve the effect of high mechanical strength, excellent electrical conductivity, and good lipophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

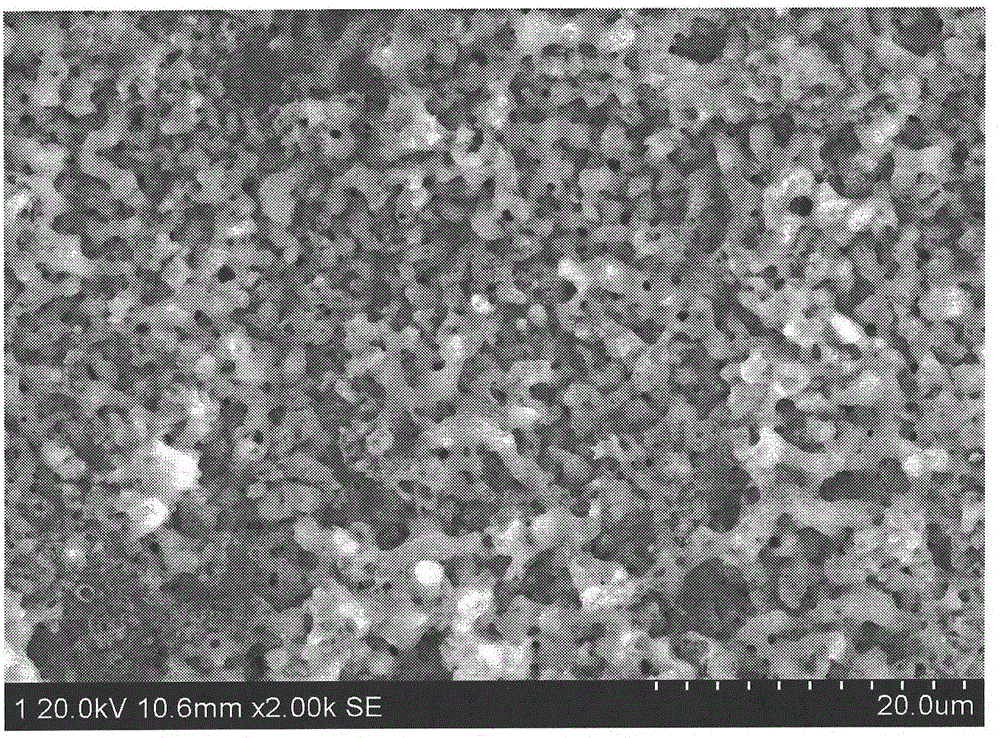

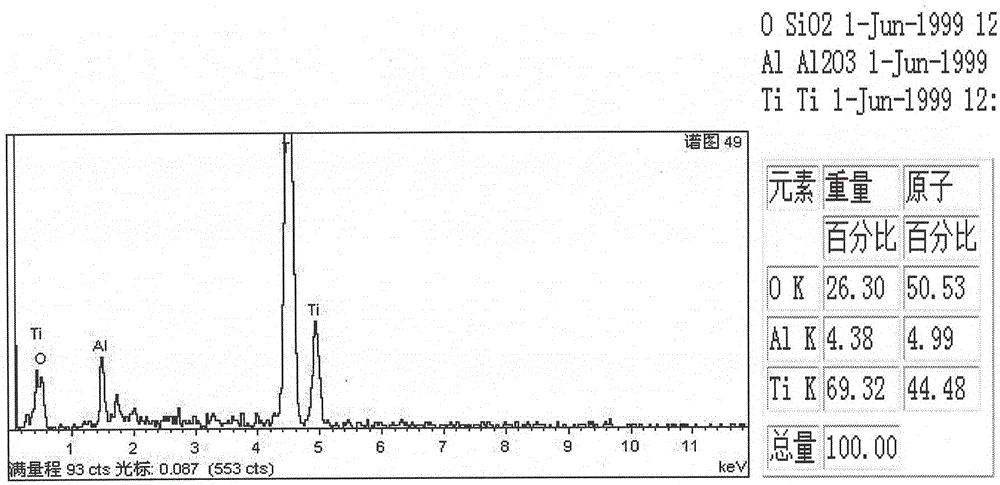

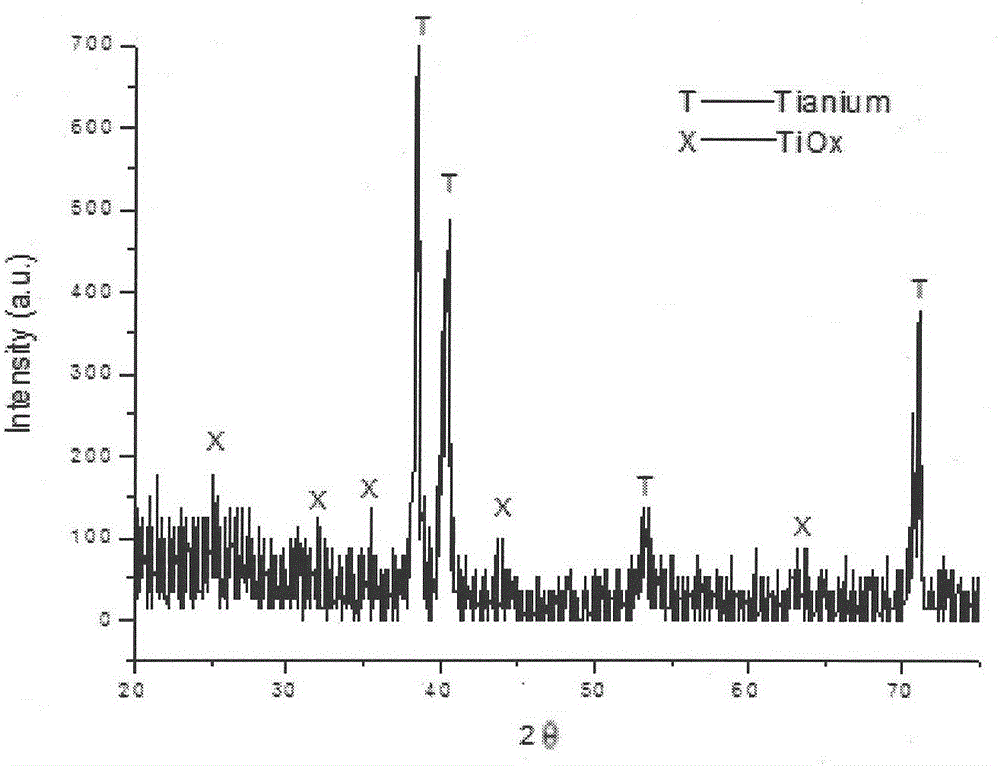

[0041] see Figure 1-Figure 3 As shown, a preparation method of titanium black coating with high strength and large specific surface area, using 25×250×1mm TC4 alloy strip as the sample, the surface TiO x The production process of titanium black coating is as follows:

[0042] Step 1. Substrate pretreatment: wash in a mixed solution containing 40g / L sodium hydroxide, 30g / L sodium carbonate and 15g / L sodium silicate at a temperature of 70°C and fully stirred for 10 minutes;

[0043] Step 2, initial coating preparation: oxidize in the electrolyte solution for 20 minutes under the conditions of constant voltage 550V, frequency 200Hz, and duty ratio 30%; wherein, the electrolyte solution is composed of 30g / L sodium silicate, 10ml / L Composed of glycerin and water;

[0044] Step 3. Plasma cleaning: evacuate to 50Pa, inject argon gas at 150Pa, heat up to 300°C, voltage 500V, and process for 15 minutes;

[0045] Step 4, TiO x Modification treatment: raise the temperature to 500°C,...

Embodiment 2

[0047] see Figure 4 As shown, a preparation method of titanium black coating with high strength and large specific surface area adopts 25 × 250 × 1mm TC4 alloy strip as the sample, and the manufacturing process of the TiOx titanium black coating on its surface is as follows:

[0048] Step 1. Substrate pretreatment: wash in a mixed solution containing 30g / L sodium hydroxide, 20g / L sodium carbonate and 10g / L sodium silicate at a temperature of 50°C and fully stirred for 15 minutes;

[0049] Step 2, initial coating preparation: Under the conditions of constant voltage 350V, frequency 500Hz, and duty ratio 50%, oxidize in the electrolyte solution for 90 minutes; wherein, the electrolyte solution is composed of 5g / L sodium metaphosphate, 3ml / L three Composition of ethanolamine and deionized water;

[0050] Step 3. Plasma cleaning: evacuate to 50Pa, inject argon gas at 300Pa, heat up to 100°C, voltage 400V, and process for 20 minutes;

[0051] Step 4, TiO x Modification treatmen...

Embodiment 3

[0053] see Figure 5 Shown, a kind of preparation method of high-strength, large specific surface area titanium black coating, adopts the TC4 alloy lath of 25 * 250 * 1mm as sample, and the manufacturing process of its surface TiOx titanium black coating is as follows:

[0054] Step 1. Substrate pretreatment: in acetone solution, use ultrasonic cleaning for 10 minutes;

[0055] Step 2. Prefabricate the inner porous structure layer of the pot body: under the conditions of constant voltage 350V, frequency 1000Hz, and duty cycle 8%, oxidize in the electrolyte solution for 60 minutes; wherein, the electrolyte solution consists of 15g / L sodium phosphate, 10ml / EDTA (ethylenediaminetetraacetic acid) and deionized water of Ld are composed;

[0056] Step 3. Plasma cleaning: evacuate to 50Pa, inject argon gas at 200Pa, heat up to 250°C, voltage 500V, and process for 10 minutes;

[0057] Step 4, TiO x Modification treatment: raise the temperature to 350°C, and perform periodic modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com