Red germanate long-afterglow luminescent material and preparation method thereof

A long afterglow luminescence and germanate technology, applied in the field of luminescent materials and long afterglow luminescent materials, can solve the problems of complex preparation process, easy deliquescence and high cost of raw materials, and achieves good chemical stability, pure luminescence color, and cheap and easy raw materials. the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

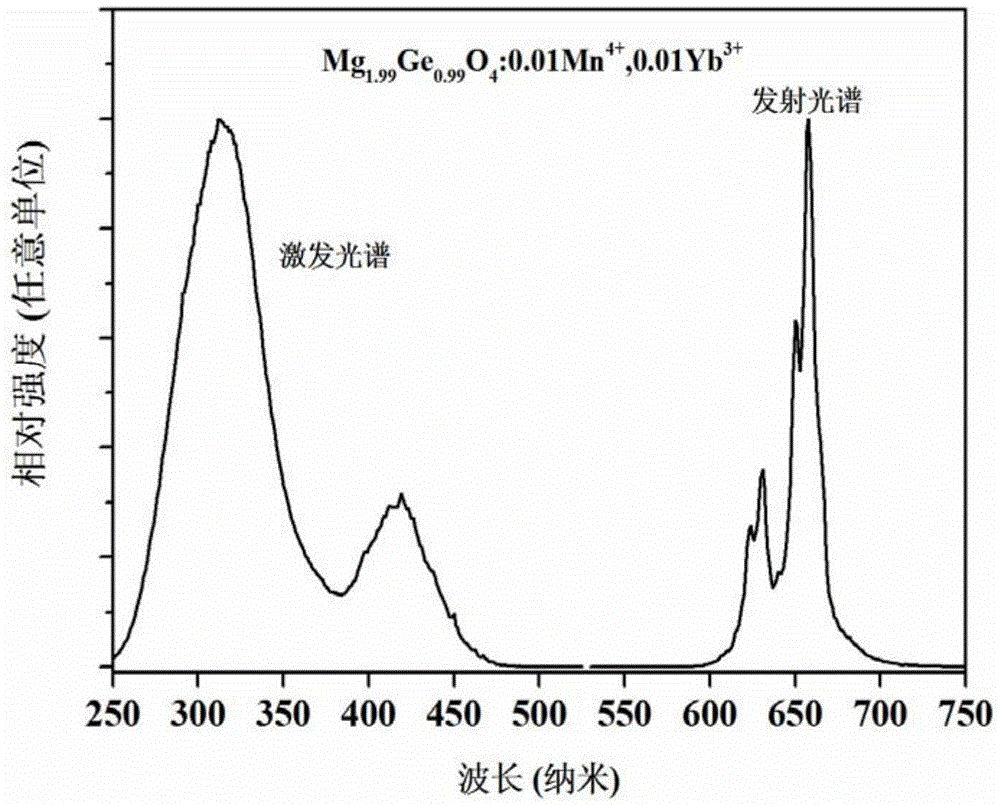

[0022] Accurately weigh 0.8039g of magnesium oxide (MgO), germanium oxide (GeO 2 ) 1.0355g, manganese dioxide (MnO 2 )0.0087g and ytterbium oxide (Yb 2 o 3 ) 0.0098g. Grind the above raw materials in an agate mortar for about 1 hour, mix the raw materials thoroughly, then transfer them to a corundum crucible, calcinate them in an air furnace at 1350°C for 3 hours, and cool them down to room temperature naturally. The body color obtained after grinding is white The powder is germanate red long-lasting luminescent material (Mg 1.99 Ge 0.99 o 4 :0.01Mn 4+ ,0.01Yb 3+ ). The XRD spectrum of the red long-lasting luminescent material is as follows: figure 1 As shown, the excitation and emission spectra are as figure 2 As shown, the thermoluminescence curve is as image 3 As shown, the afterglow spectrum is shown as Figure 4 shown. From figure 1 The XRD spectrum and Mg of the red long afterglow material luminescent material are shown in 2 GeO 4 The standard chromatog...

Embodiment 2

[0025] Accurately weigh 0.8019g of magnesium oxide (MgO), germanium oxide (GeO 2 ) 1.0355g, manganese dioxide (MnO 2 )0.0087g and ytterbium oxide (Yb 2 o 3 ) 0.0197g. Grind the above raw materials in an agate mortar for about 1 hour, mix the raw materials thoroughly, then transfer them to a corundum crucible, calcinate them in an air furnace at 1350°C for 3 hours, and cool them down to room temperature naturally. The body color obtained after grinding is white The powder is germanate red long afterglow luminescent material. After the luminescent material was irradiated by a 254nm ultraviolet lamp for 5 minutes, it was moved to a dark room, and the ultraviolet lamp was turned off. The sample emitted bright red light with an afterglow time of up to 3 hours.

[0026] The germanate-based long-lasting fluorescent material of this embodiment does not absorb moisture and is resistant to acid and alkali corrosion (except hydrofluoric acid), compared to the red long-lasting fluores...

Embodiment 3

[0028] Accurately weigh 0.7979g of magnesium oxide (MgO), germanium oxide (GeO 2 ) 1.0355g, manganese dioxide (MnO 2 )0.0087g and ytterbium oxide (Yb 2 o 3 ) 0.0394g. Grind the above raw materials in an agate mortar for about 1 hour, mix the raw materials thoroughly, then transfer them to a corundum crucible, calcinate them in an air furnace at 1350°C for 3 hours, and cool them down to room temperature naturally. The body color obtained after grinding is white The powder is germanate red long afterglow luminescent material. After the luminescent material was irradiated by a 254nm ultraviolet lamp for 5 minutes, it was moved to a dark room, and the ultraviolet lamp was turned off. The sample emitted bright red light with an afterglow time of up to 3 hours.

[0029] The germanate-based long-lasting fluorescent material of this embodiment does not absorb moisture and is resistant to acid and alkali corrosion (except hydrofluoric acid), compared to the red long-lasting fluores...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com