Roxburgh rose fruit wine and making process thereof

A thorn pear fruit wine and thorn pear technology, applied in the field of thorn pear fruit wine and its brewing technology, can solve the problems of low utilization rate of raw materials, easy to destroy active ingredients, etc., and achieve the effect of stable color, transparent wine body and avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

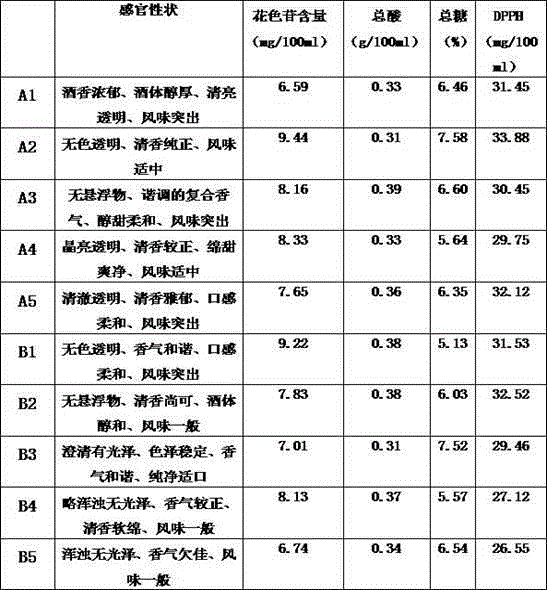

Examples

Embodiment 1

[0039] ①Clean the mature Rosa roxburghii and chop it into roxburghii granules, put the roxburghies groats into 2.5 times its weight in white wine with an alcohol content of 67% and soak for 10 days, take them out after soaking to make soaking wine and Rosa roxburghii chips granules, and beating roxburghii crumbs, adding sodium ascorbate with a weight of 1.5% in the beating process of roxburghines roxburghii, to obtain roxburghii slurries;

[0040] ②The roxa pear slurry is subjected to compound enzyme treatment; the roxburghii slurry, pectinase, and cellulase (weight ratio: 100:0.6:0.2) are evenly mixed and then enzymatically hydrolyzed at 50°C for 3 hours;

[0041] ③ adding glucose to the roxburghii slurry after the enzyme treatment to adjust the sugar concentration is 27%, adding citric acid to adjust the total acid content is 1.1mg / 100ml, and the mixed solution is obtained;

[0042] ④ Dissolve white sugar and prepare a sugar solution with a concentration of 6%. After boiling...

Embodiment 2

[0048]①Clean the ripe thorn pears and chop them into broken thorn pears, put the broken thorns in 70% white wine with 3 times its weight and soak them for 10 days, take them out after soaking to make soaking wine, broken thorns granules, and beating the roxburghii crumbs, adding 0.5 weight of sodium ascorbate during the beating process of the roxburghines, to obtain roxburghii slurries;

[0049] ②The roxa pear slurry is subjected to compound enzyme treatment; the roxburghii slurry, pectinase, and cellulase (weight ratio: 100:0.8:0.4) are evenly mixed and then enzymatically hydrolyzed at 54°C for 2.5 hours;

[0050] 3. Adding glucose to the roxburghii slurry after the enzyme treatment to adjust the sugar concentration is 25%, adding citric acid to adjust the total acid content is 1.4mg / 100ml, and the mixed solution is obtained;

[0051] ④ Dissolve white sugar and prepare a sugar solution with a concentration of 10%. After boiling, cool to 27°C, add active dry yeast (100:11 by w...

Embodiment 3

[0057] ①Clean the mature Rosa roxburghii and chop into Rosa roxburghii pieces, put the Rosa roxburghii chips into 3.2 times its weight and soak in white wine with an alcohol content of 62% for 10 days, take it out after soaking to make soaking wine, Rosa roxburghii chips granules, and beating roxburghii crumbs, adding 0.9 weight of sodium ascorbate during the beating process of roxburghines roxburghii, to obtain roxburghii slurries;

[0058] ② Treat the roxburghii slurries with complex enzymes; mix the roxburghies sarcophagus slurries, pectinase, and cellulase (100:1:0.5 by weight) evenly, and then carry out enzymatic hydrolysis at 54°C for 2.5 hours;

[0059] 3. Adding glucose to the roxburghii slurry after the enzyme treatment to adjust the sugar concentration is 29%, adding citric acid to adjust the total acid content is 1.5mg / 100ml, and the mixed solution is obtained;

[0060] ④ Dissolve white sugar and prepare a sugar solution with a concentration of 13%. After boiling, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com