A clinker-free white cement

A white cement, clinker-free technology, applied in cement production and other directions, can solve the problems of complex process, environmental pollution and high cost, and achieve the effects of high strength and whiteness, reducing resource shortage and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

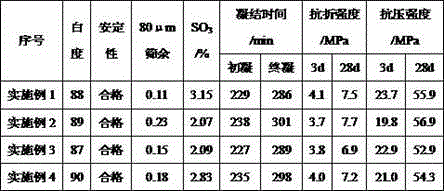

Examples

Embodiment 1

[0027] A clinker-free white cement is composed of the following raw materials in parts by weight: 65 parts of slag powder, 6 parts of gypsum, 10 parts of polished brick waste slag powder, 13 parts of calcium carbide slag powder, 5 parts of heavy calcium carbonate, hydration promotion 1 dose;

[0028] As mentioned, the hydration accelerator is prepared by the following steps: add the reactants with the molar ratio of dimethyl diallyl ammonium chloride: acrylamide: itaconic acid as 1:0.2:2 In the reaction kettle with 60% of the total mass of distilled water and 1% of the total mass of the reactants, sodium methacryl sulfonate, after 20 minutes of nitrogen deoxygenation, dropwise add 0.5% of the total mass of the reactants with a mass ratio of 1:2. White block and hydrogen peroxide are used as initiators, react for 3 hours to obtain a copolymer aqueous solution with a molecular weight in the range of 2000-8000, which is the hydration accelerator.

[0029] As stated, the whitenes...

Embodiment 2

[0035] A clinker-free white cement is composed of the following raw materials in parts by weight: 75 parts of slag powder, 5 parts of gypsum, 9 parts of polished brick waste slag powder, 10 parts of calcium carbide slag powder, 4 parts of heavy calcium carbonate, hydration promotion 0.8 part of dose;

[0036]Said, the hydration accelerator is prepared by the following steps: according to the molar ratio of dimethyl diallyl ammonium chloride: acrylamide: acrylic acid is 1:0.8:1.5, add the total mass of reactants In the reaction kettle of 50% distilled water and 1.5% of the total mass of the reactants, sodium methacrylsulfonate, after 15 minutes of deoxygenation by passing nitrogen, add dropwise 1.5% of the total mass of the reactants with a mass ratio of 1:1.5. And hydrogen peroxide as an initiator, react for 5 hours to obtain a copolymer aqueous solution with a molecular weight in the range of 2000-8000, which is the hydration accelerator.

[0037] As stated, the whiteness of...

Embodiment 3

[0043] A clinker-free white cement is composed of the following raw materials in parts by weight: 80 parts of slag powder, 4 parts of gypsum, 7 parts of polished brick waste slag powder, 7 parts of calcium carbide slag powder, 4 parts of heavy calcium carbonate, hydration promotion 0.5 part of agent;

[0044] Said, the hydration accelerator is prepared by the following steps: by dimethyl diallyl ammonium chloride: acrylamide: the molar ratio of maleic acid is 1: 1.5: 0.8 and add the reactant In the reaction kettle with 40% distilled water and 3% sodium methacrylate in the total mass of the reactants, after 15 minutes of deoxygenation with nitrogen, add dropwise 0.5-5% of the total mass of the reactants at a mass ratio of 1:1 The hanging white block and hydrogen peroxide are used as the initiator, and the aqueous solution of the copolymer with a molecular weight in the range of 2000-8000 is obtained after reacting for 6 hours, which is the hydration accelerator.

[0045] As st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com