Diamond material ohmic contact electrode and its preparation method and application

An ohmic contact electrode and diamond technology, which is applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of poor thermal stability, poor adhesion between gold and diamond materials, and increased resistance, and reduce specific contact resistivity. , Improve electrical properties, increase the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

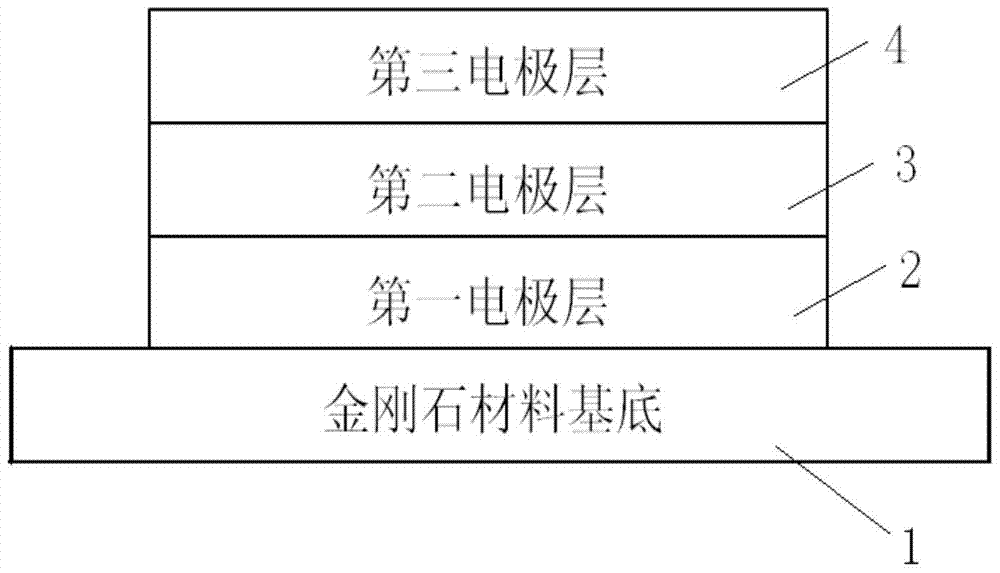

[0055] A method for preparing a diamond material ohmic contact electrode comprises the following steps:

[0056] 1) Use microwave plasma chemical vapor deposition (MPCVD) technology to deposit a layer of high-quality single crystal diamond epitaxial film of about 1 micron on the cleaned high-temperature and high-pressure (HPHT) diamond material substrate, for use;

[0057] 2) Use a mixed acid solution (1:1) of sulfuric acid and nitric acid to clean the deposited epitaxial film in a water bath at 250°C for about 1 hour to remove the carbon elements in the non-diamond phase on the surface;

[0058] 3) Use MPCVD equipment to hydrogenate the diamond epitaxial film, the plasma power is about 1000W, and the processing time is about 5 minutes;

[0059] 4) Use acetone, isopropanol, and deionized water to ultrasonically clean the sample, and dry it;

[0060] 5) Spin-coat a layer of AZ5214 photoresist on the surface of the sample, bake the spin-coated photoresist-coated single crystal ...

Embodiment 2

[0066] A method for preparing a diamond material ohmic contact electrode comprises the following steps:

[0067] 1) Deposit a layer of high-quality single-crystal diamond epitaxial film of about 1 micron on the cleaned high-temperature and high-pressure (HPHT) diamond substrate by using hot filament chemical vapor deposition (HFCVD) technology, for use;

[0068] 2) Use a mixed acid solution (1:1) of sulfuric acid and nitric acid to clean the deposited epitaxial film in a water bath at 250°C for about 1 hour to remove the carbon elements in the non-diamond phase on the surface;

[0069] 3) Use MPCVD equipment to hydrogenate the diamond epitaxial film, the plasma power is about 1000W, and the processing time is about 5 minutes;

[0070] 4) Use acetone, isopropanol, and deionized water to ultrasonically clean the sample, and dry it;

[0071] 5) Spin-coat a layer of AZ5214 photoresist on the surface of the sample, bake the spin-coated photoresist-coated single crystal diamond sam...

Embodiment 3

[0076] A method for preparing a diamond material ohmic contact electrode comprises the following steps:

[0077] 1) Use a mixed acid solution (1:1) of sulfuric acid and nitric acid to clean the high-temperature and high-pressure (HPHT) diamond substrate in a water bath at 250°C for about 1 hour to remove the carbon element of the non-diamond phase on the surface;

[0078] 2) Use MPCVD equipment to hydrogenate the diamond substrate, the plasma power is about 1000W, and the processing time is about 5 minutes;

[0079] 3) Use acetone, isopropanol, and deionized water to ultrasonically clean the sample, and dry it;

[0080] 4) Spin-coat a layer of AZ5214 photoresist on the surface of the sample, bake the spin-coated photoresist-coated single crystal diamond sample at 95°C for 90 seconds, use the designed mask plate for UV lithography exposure for 6.5s, and develop 45s to remove the exposed photoresist, leaving the design pattern;

[0081] 5) Place the photolithographic sample in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com