Coating structure with sandwich nano ceramic layer and preparation method of coating structure

A nano-ceramic, sandwich structure technology, applied in the coating, metal material coating process, layered products and other directions, can solve the high temperature nano-ceramic coating without substantial technological breakthrough, limited application scope, poor controllability, etc. problems, to achieve excellent high temperature resistance, reduced preparation steps, and the effect of dense coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

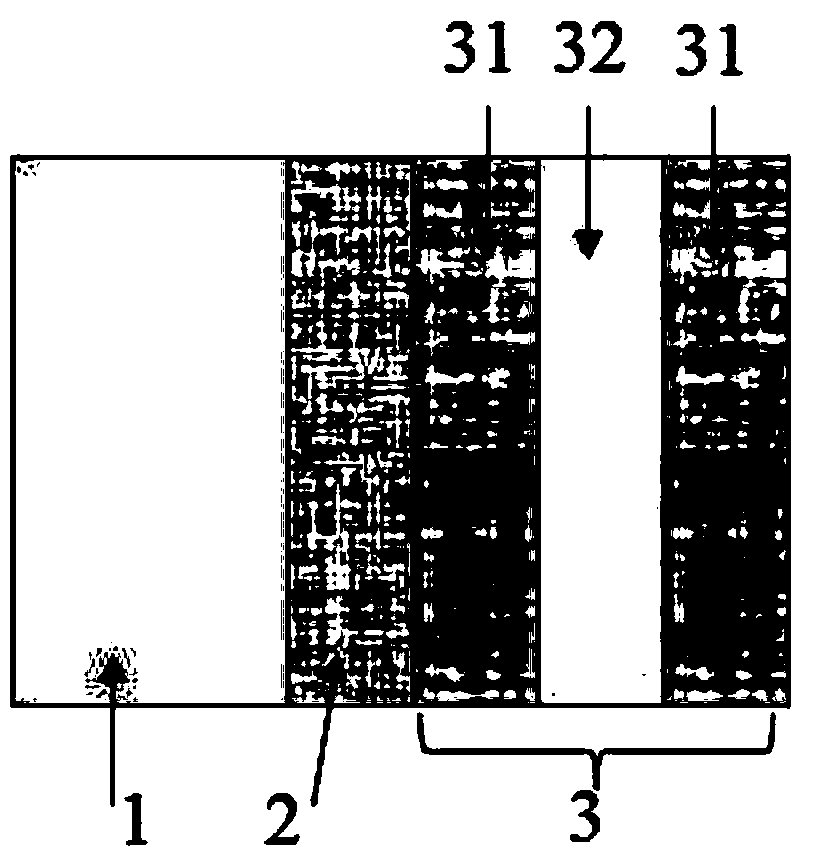

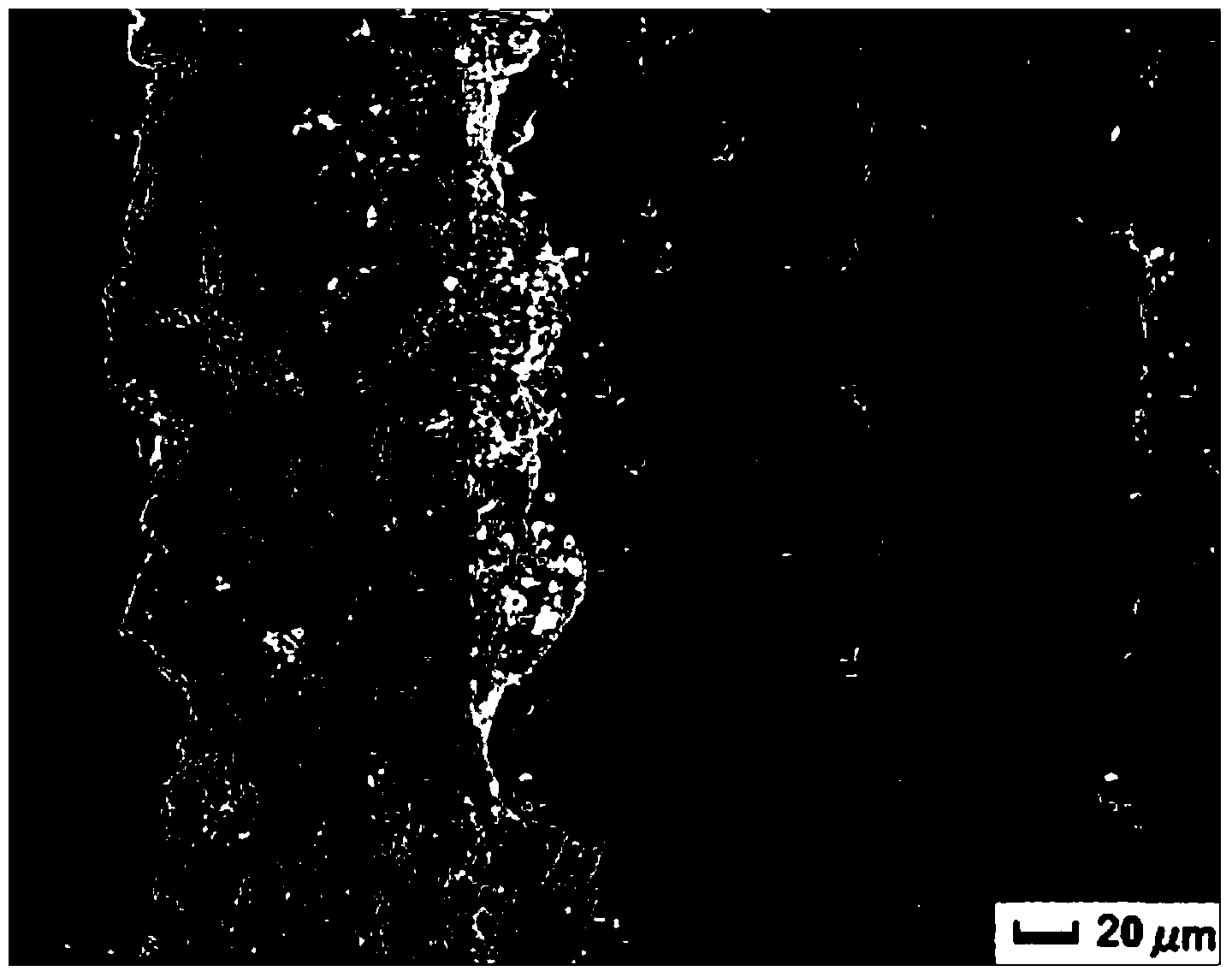

[0028] The invention provides a coating structure with a sandwich nano-ceramic layer and a preparation method. The invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, 1 is a base, 2 is a transition layer, 3 is a ceramic layer, and the ceramic layer 3 is a sandwich structure, the upper and lower layers of the sandwich are ordinary ceramic layers 31, and the middle layer is a nano-ceramic layer 32.

[0029] According to an embodiment of the present invention, Al is prepared on a TiAl alloy substrate 1 2 o 3 Nano ceramic coating. The specific operation is as follows:

[0030] (1) Clean the substrate 1 with acetone and alcohol, and then sandblast it for later use;

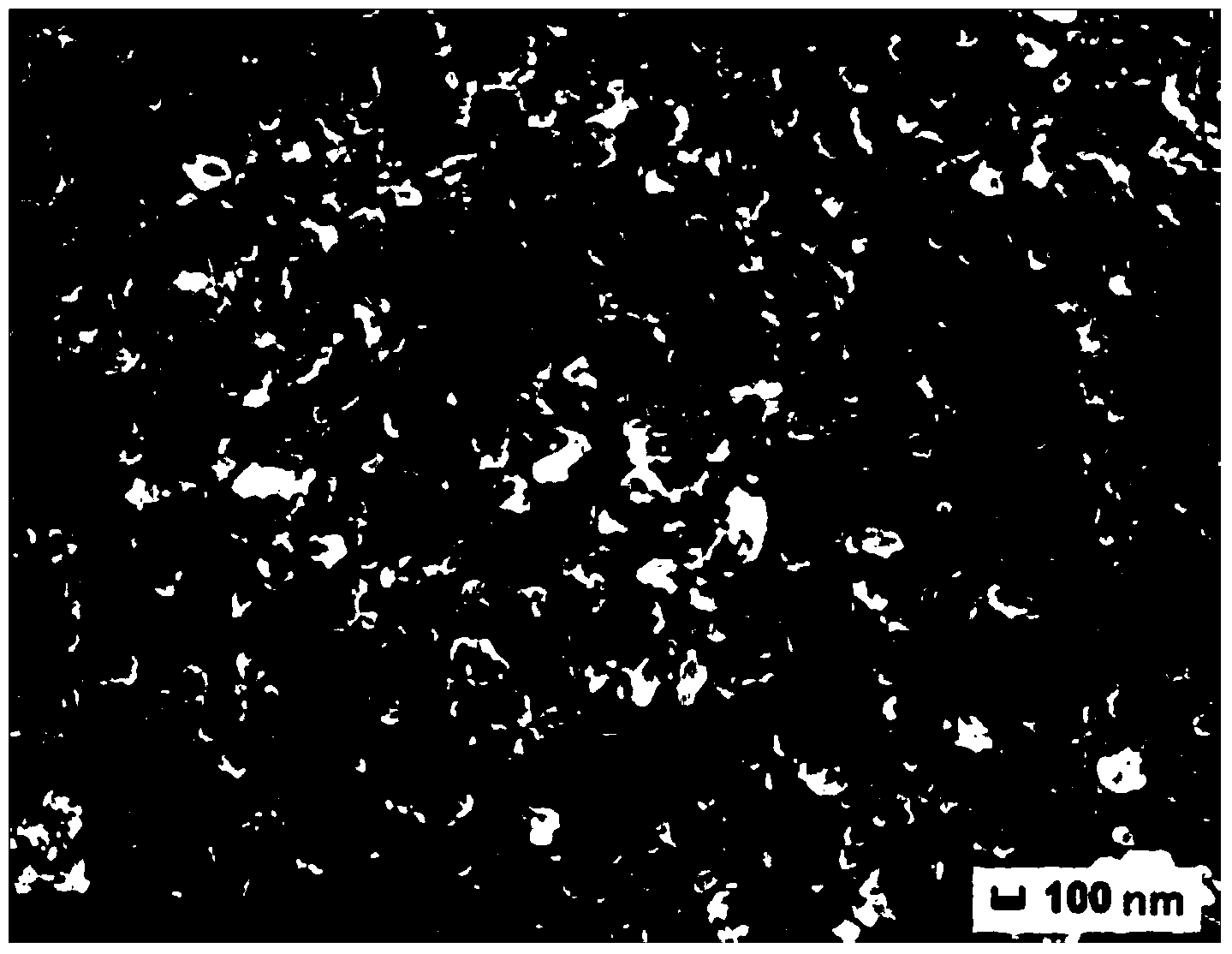

[0031] (2) Pure Ti powder, Al powder and Al with a particle size of 20nm 2 o 3 Nano ceramic powder (such as figure 2 Shown) is configured according to the mass ratio of 4.3:4.7:1, and the transition layer powder is obtained by mixing in a ball mill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com