Jointing material for ladle nozzle brick cups

A technology for nozzle block and joint material, which is applied in the field of high-temperature materials and metallurgy, can solve the problems of adhesion, erosion resistance, mechanical strength reduction, split block block cracking and separation, and reducing the service life of block blocks. Good erosion resistance, saving production costs, and enhancing the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

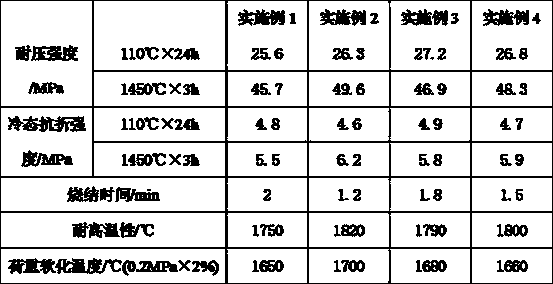

Examples

Embodiment 1

[0024] A joint material for ladle nozzle seat brick, which is made of adhesive, urotropine, powder, 3-aminopropyltrimethoxysilane, and 96% industrial alcohol according to the ratio of 1:0.4:1.8:0.2: Made with a weight ratio of 1.8;

[0025] In the powder, the weight ratio of magnesia: graphite: silicon carbide: magnesia-aluminum spinel is 1:0.5:0.3:0.3; wherein the magnesia is 97% fused magnesia, the particle size is 150 mesh, and the graphite is scale The particle size of graphite is 80 mesh; the particle size of silicon carbide is 1 μm; the particle size of magnesium aluminum spinel is 0.8 μm.

[0026] The weight ratio of phenolic resin and epoxy resin in the binder is 1:1.2; Wherein the phenolic resin is xylene modified phenolic resin, fluidity 40mm, free phenol 2%, particle size is 200 orders.

[0027] Weigh and mix each raw material in proportion and stir until uniform. When using, apply joint material evenly on the parts of the ladle nozzle seat bricks that need to be b...

Embodiment 2

[0029] A joint material for ladle nozzle seat brick, which is made of adhesive, urotropine, powder, 3-aminopropyltrimethoxysilane, and 96% industrial alcohol according to the ratio of 1:0.6:2:0.4: Made with a weight ratio of 1.9;

[0030] In the powder, the weight ratio of magnesia: graphite: silicon carbide: magnesium aluminum spinel is 1:0.7:0.5:0.6; wherein the magnesia is 97% fused magnesia, the particle size is 180 mesh, and the graphite is scale The particle size of graphite is 100 mesh; the particle size of silicon carbide is 2 μm; the particle size of magnesium aluminum spinel is 0.5 μm.

[0031] The weight ratio of phenolic resin and epoxy resin in the binder is 1:1.3; wherein the phenolic resin is a xylene modified phenolic resin with a fluidity of 60mm, free phenol 1.8%, and a particle size of 200 mesh.

[0032] Weigh and mix each raw material in proportion and stir until uniform. When using, apply joint material evenly on the parts of the ladle nozzle seat bricks ...

Embodiment 3

[0034] A joint material for ladle nozzle seat brick, which is made of adhesive, urotropine, powder, 3-aminopropyltrimethoxysilane, and 96% industrial alcohol according to 1:0.8:2.2:0.6: Made with a weight ratio of 2.2;

[0035] In the powder, the weight ratio of magnesia: graphite: silicon carbide: magnesia-aluminum spinel is 1:0.9:0.4:0.5; wherein the magnesia is 97% fused magnesia, the particle size is 200 mesh, and the graphite is scale The particle size of graphite is 90 mesh; the particle size of silicon carbide is 3 μm; the particle size of magnesium aluminum spinel is 0.2 μm.

[0036] The weight ratio of phenolic resin and epoxy resin in the binder is 1:1.4; Wherein the phenolic resin is xylene modified phenolic resin, fluidity 80mm, free phenol 2.2%, particle size is 200 orders.

[0037] Weigh and mix each raw material in proportion and stir until uniform. When using, apply joint material evenly on the parts of the ladle nozzle seat bricks that need to be bonded, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com