A kind of cationic silk fibroin and preparation method thereof

A silk fibroin, cationization technology, which is applied in the preparation methods of peptides, chemical instruments and methods, and other methods of inserting foreign genetic materials, etc., can solve the problem of reducing adsorption, low transfection efficiency, and affecting the combination of carriers and target cells. efficiency and other issues, to achieve the effect of simple method, single product, good biocompatibility and biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation of protamine cationized silk fibroin, concrete steps are as follows:

[0026] (1) Put 100 g tussah raw silk into 5 L Na with a mass concentration of 0.25 % 2 CO 3 In aqueous solution, treatment at 98-100°C for 45 min, repeated three times to degumming silk, washing and drying fully to obtain tussah silk fibroin fiber. Add the tussah silk fiber into the molten calcium nitrate tetrahydrate, stir and dissolve at 105 ℃. The obtained mixed solution was put into a dialysis bag (the molecular weight cut-off was 9-12 KDa), and dialyzed in deionized water for 4 days to remove impurities to obtain a pure tussah silk fibroin protein solution. Adjust the concentration of tussah silk solution to 20 mg / ml, and filter with a 0.22 μm microporous membrane;

[0027] (2) Dissolve sulfo-SMCC in PBS solution (phosphate buffered saline, pH=7.4) and prepare a solution with a concentration of 1mg / ml. Take 1 ml of sulfo-SMCC solution and slowly add it dropwise to 20 ml of th...

Embodiment 2

[0034] 1. Use boiling Na with a concentration of 3.5 ‰ 2 CO 3 The silkworm cocoon was treated with solution for 3 times, 30 min each time, to degumming the silk, and after washing and drying thoroughly, the silk fibroin fiber was obtained. Add celestial silk fibroin fiber into molten calcium nitrate tetrahydrate, stir and dissolve at 90 °C. The obtained mixed solution was put into a dialysis bag (the molecular weight cut-off was 9-12 KDa), and dialyzed with deionized water for 4 days to remove impurities to obtain a pure silk fibroin solution. Adjust the concentration of cecropin solution to 20 mg / ml, and filter it with a 0.22 μm microporous membrane;

[0035] 2. Dissolve sulfo-SMCC in PBS solution (pH=7.4), and prepare a solution with a concentration of 1 mg / ml. Take 1 ml of sulfo-SMCC solution and slowly add it dropwise to 20 ml of the silk fibroin solution obtained in step 1, stir magnetically for 2 h at 4 °C, and centrifuge the solution with an ultrafiltration centrifug...

Embodiment 3

[0043] Preparation of cationized silk fibroin / gene carrier, the specific steps are as follows: adjust the concentration of the cationized tussah silk fibroin solution with sample number 1 obtained in Example 1 of the present invention to 0.01 mg / ml, and filter it with a 0.22 μm microporous membrane , adjust the DNA concentration to 0.01 mg / ml with sterile water. Slowly stir the silk fibroin solution containing 4 μg cationized silk fibroin at 2-8°C with an electric stirrer at a speed of 60 rpm. After applying a shear force for 15 min, add 2 μg DNA solution, vortexed for 30 s, warmed up to 25°C, let the complex solution stand for 45 min, and self-assembled into a cationic silk fibroin / DNA complex by electrostatic interaction, which was recorded as sample 19, the mass of cationic silk fibroin and DNA The ratio is 2:1.

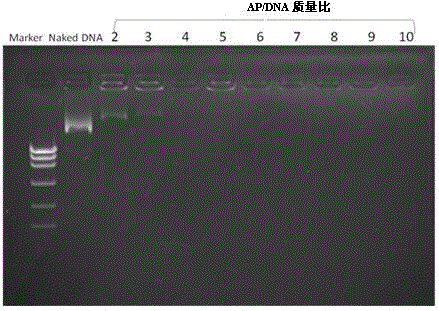

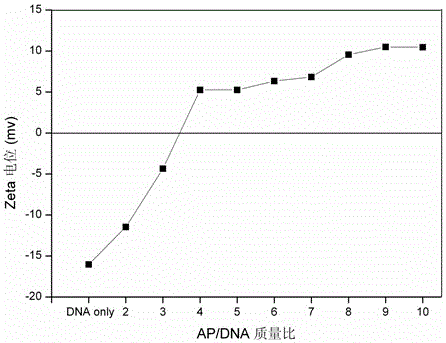

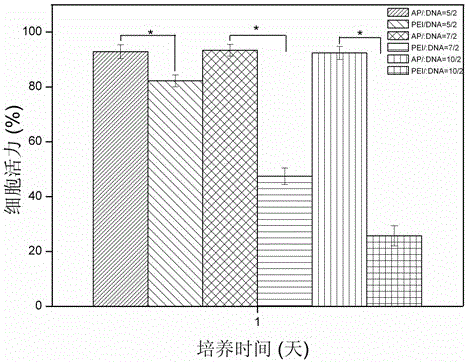

[0044] With reference to the above method, the mass ratios of cationized silk fibroin to DNA were respectively 3:1, 4:1, 5:1, 6:1, 7:1 for the samples whose samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com