Chewable nutritional supplement plant soft capsule and preparation method thereof

A technology for nutritional supplements and soft capsules, applied in the field of nutritional supplements plant soft capsules and their preparation, can solve the problems of production and sales restrictions of gelatin soft capsules, unfavorable large-scale production actual operations, inconsistency with dietary habits, and the like, and achieves a continuous production method. Uninterrupted, significant curative effect, powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

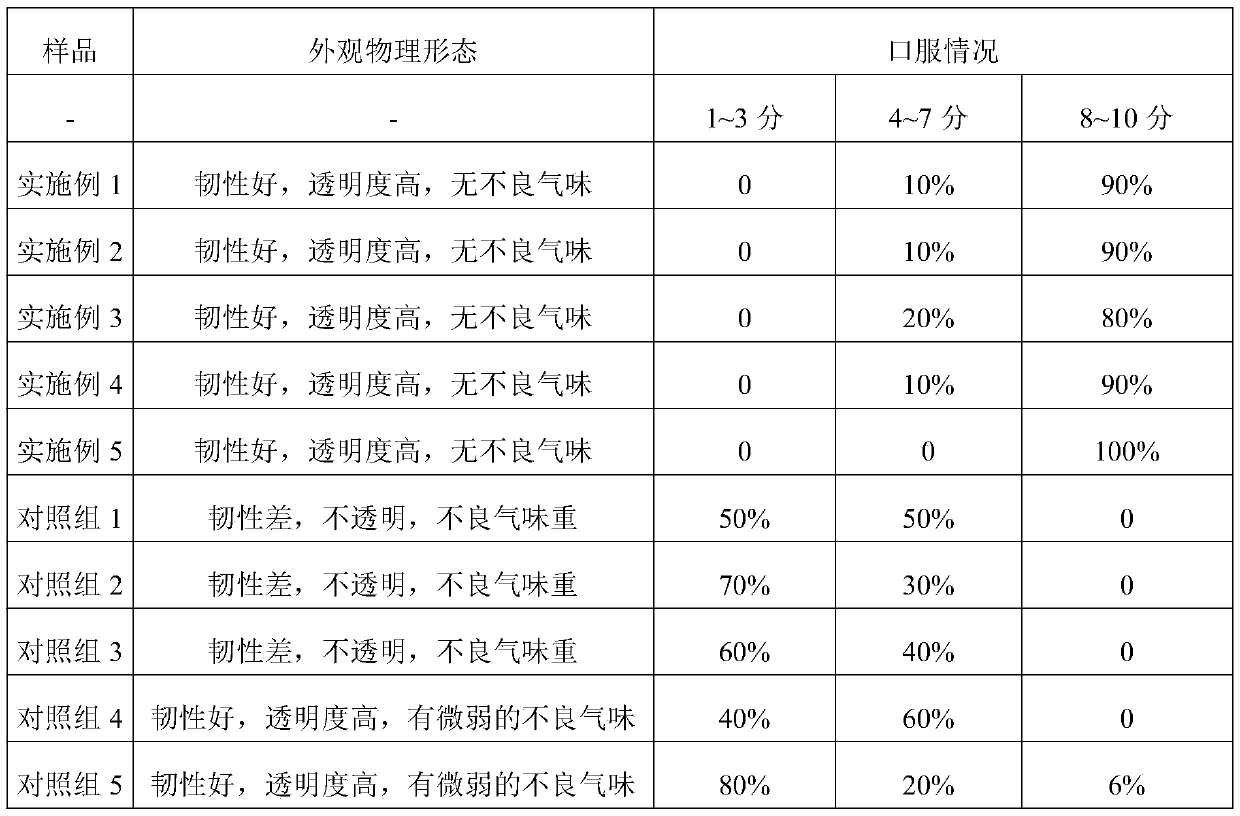

Examples

Embodiment 1

[0029] A chewable nutritional supplement plant soft capsule is prepared, comprising the following steps:

[0030] Step 1, ingredients and weighing:

[0031] Weigh according to the required parts by weight: 10 parts of seaweed powder, 1 part of mushroom powder, 1 part of spinach powder, 1 part of milk mineral salt, 1 part of malt powder, 1 part of milk powder, 2 parts of lactitol, 0.1 part of Luo Han Guo powder, 82.9 parts of olive oil, seaweed powder, mushroom powder and spinach powder are respectively micro-cracked seaweed powder, super-micro-cracked mushroom powder and super-fine-cracked spinach powder, all of which are selected fresh seaweed, mushrooms and spinach, After sorting, cleaning, boiling water and aging, freeze-drying under vacuum conditions into a dehydrated product with a water content of less than 5%, and then pulverizing with an ultrafine pulverizer until the average particle size is below 2 microns, the obtained seaweed is ultra-fine Micro-cracked powder, mu...

Embodiment 2

[0038] A chewable nutritional supplement plant soft capsule is prepared, comprising the following steps:

[0039] Step 1, ingredients and weighing:

[0040] Weigh according to the required parts by weight: 20 parts of seaweed powder, 10 parts of mushroom powder, 2 parts of spinach powder, 10 parts of milk mineral salt, 2 parts of malt powder, 2 parts of milk powder, 6 parts of lactitol, 6 parts of monk fruit powder, 40 parts of olive oil, seaweed powder, mushroom powder and spinach powder are seaweed supermicro-cracked powder, mushroom superfine-cracked powder and spinach superfine-cracked powder, and are all selected fresh seaweed, mushrooms and spinach, After sorting, cleaning, boiling water and aging, freeze-drying under vacuum conditions into a dehydrated product with a water content of less than 5%, and then pulverizing with an ultrafine pulverizer until the average particle size is below 2 microns, the obtained seaweed is ultra-fine Micro-cracked powder, mushroom super-...

Embodiment 3

[0047] A chewable nutritional supplement plant soft capsule is prepared, comprising the following steps:

[0048] Step 1, ingredients and weighing:

[0049] Weigh according to the required parts by weight: 12 parts of seaweed powder, 3 parts of mushroom powder, 1.5 parts of spinach powder, 3 parts of milk mineral salt, 1 part of malt powder, 1 part of milk powder, 2 parts of lactitol, 0.1 part of monk fruit powder, The rest is 60 parts of olive oil, seaweed powder, mushroom powder and spinach powder are seaweed superfine wall-breaking powder, mushroom superfine wall-breaking powder and spinach superfine wall-breaking powder, all of which are selected fresh seaweed, mushroom and spinach powder. The spinach is first sorted, cleaned, blanched and ripened in boiling water, then freeze-dried under vacuum conditions to obtain a dehydrated spinach with a water content of less than 5%, and then pulverized by an ultrafine pulverizer until the average particle size is less than 2 micron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com