Preparation process of molybdenum carbide-doped ruthenium-based alloy diffusion barrier layer for copper-free seed crystal interconnection

A ruthenium-based alloy and preparation process technology, applied in the field of preparation of new diffusion barrier layers, to achieve the effects of less pollutants, low cost, and strong oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

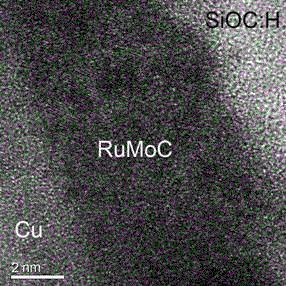

[0029] The molybdenum carbide-doped ruthenium-based alloy (RuMoC) barrier layer preparation process used in this embodiment includes the following steps:

[0030] a. Clean the substrate material:

[0031] Put the monocrystalline silicon (Si) / carbon-doped silicon oxide (SiOC:H, 200 nm) multi-layer structure substrate material into acetone and absolute ethanol for 20 minutes for ultrasonic cleaning respectively, and put it into a vacuum chamber after drying. Then evacuate to 2.0×10 -4 Pa;

[0032] b. Treatment of the substrate before deposition: bias backsputtering;

[0033] Under the vacuum condition of step a, the Si / SiOC:H substrate was cleaned by bias backsputtering for 5 minutes to remove impurities on the surface of the Si / SiOC:H substrate, the backsputter power was 100 W, and the backsputter bias was -500 V ; The backsplash gas is argon (Ar); the working vacuum is 1.0 Pa;

[0034] c. Deposition of RuMoC barrier film:

[0035] Using reactive magnetron sputtering tech...

Embodiment 2、3

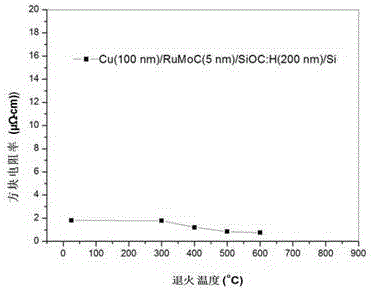

[0039] During the deposition of the RuMoC barrier layer, the deposition bias and sputtering power have an impact on the composition, uniformity and thickness of the coating. The operating steps, conditions and parameters of the RuMoC barrier layer in this example are basically the same as those in Example 1. Only by changing the deposition bias or sputtering power of the magnetron Ru target and the magnetron MoC target when depositing the RuMoC barrier layer, for example, the selected deposition bias is -50 V, -100 V, -150 V, -200 V , or the sputtering power is 50 W, 100 W, 150 W, 200 W, the composition, uniformity and thickness of the RuMoC barrier layer can be adjusted, and then the thickness, resistivity and high temperature resistance of the RuMoC barrier layer can be adjusted. , to meet the usage requirements of the product.

Embodiment 4

[0041] Because in the process of depositing the RuMoC barrier layer, the content of C has a great influence on the composition, structure and electrical properties of the barrier layer. The operating steps, conditions and parameters of the RuMoC barrier layer in this example are basically the same as those in Example 1. Only by changing the magnetron MoC target power to change the content of C and Mo when depositing the barrier layer of RuMoC barrier layer to change the coating structure and composition, such as the selected magnetron MoC target power is 50 W, 100 W, 150 W, 200 W, and then adjusting the percentage of Ge atoms in the range of 6.5, 12.5, 17.5, 25 (%) can control the composition and structure of the RuMoC barrier layer, and then realize the thickness, resistivity and high temperature resistance of the RuMoC barrier layer, etc. The performance is adjusted to meet the usage needs of the product application.

[0042] The used substrate material of the present inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com