Catalyst for high temperature catalytic decomposition of N2O and preparation method thereof

A high-temperature catalysis and catalyst technology, which is applied in the direction of physical/chemical process catalysts, separation methods, chemical instruments and methods, etc., can solve the problems of poor high temperature resistance stability and inability to meet high airspeed operation, etc., and achieve high lateral compressive strength and appearance Uniform, low and high temperature active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

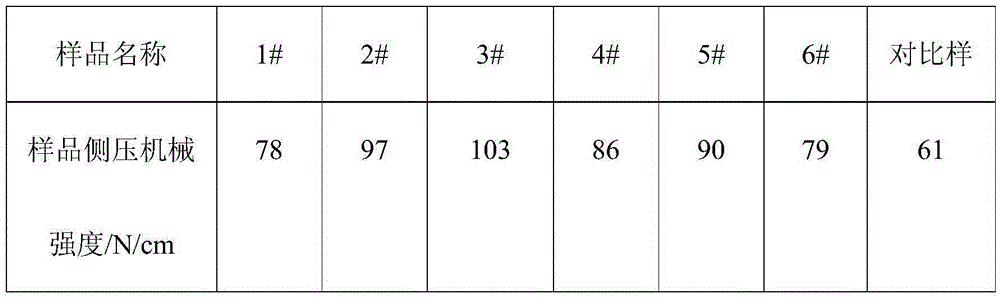

Examples

preparation example Construction

[0035] 1. Preparation of titanium, magnesium, zirconium, cerium solid solution carrier

[0036] (1) Preparation of carrier powder

[0037] Inject 1.0L of deionized water into the neutralization tank and heat to 40-90°C, weigh 230g of titanium nitrate, 182.3g of magnesium nitrate, 656.7g of cerium nitrate, 162.3g of zirconium nitrate and 496.5g of citric acid into the In the tank, keep stirring vigorously to maintain the temperature at 40-90°C, and adjust the pH. During the addition process, keep stirring vigorously, and continue to stir for 2 hours after the addition is completed to complete the reaction. After the reaction is complete, add 65.7g of pseudo-boehmite or aluminum hydroxide into the neutralization tank and stir evenly. Then stand still, if a small amount of clear liquid is formed on the upper part of the neutralization tank solution, the upper clear liquid is sucked out with a siphon, and the lower part of the sediment is released through the lower valve of the ...

Embodiment 1

[0044] Dissolve 300g of cobalt nitrate in 500mL of deionized water, stir to dissolve and place in a water bath at a constant temperature of 40-90°C. Put 200g of the prepared carrier in the solution for immersion for 30min, dry at 120°C for 60min after impregnation, and roast at 400°C for 10h after drying; impregnate, dry, dry, and calcinate again to obtain 1# finished catalyst.

Embodiment 2

[0046] Dissolve 300g of cobalt nitrate and 43.5g of praseodymium nitrate in 500mL of deionized water, stir to dissolve and place in a water bath at a constant temperature of 40-90°C. Put 200g of the prepared carrier in the solution for immersion for 30min, dry at 120°C for 60min after impregnation, and roast at 500°C for 10h after drying; impregnate again, dry, dry, and calcinate to obtain 2# finished catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com