Modified zirconium oxide particle powder, modified zirconium oxide particle dispersed sol and making method thereof

A manufacturing method and technology of zirconia, applied in the direction of zirconia, etc., can solve the problems of reduced surface potential, reduced dispersibility, particle agglomeration, etc., and achieve the effects of excellent dispersion stability, reduced transportation costs, and excellent fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

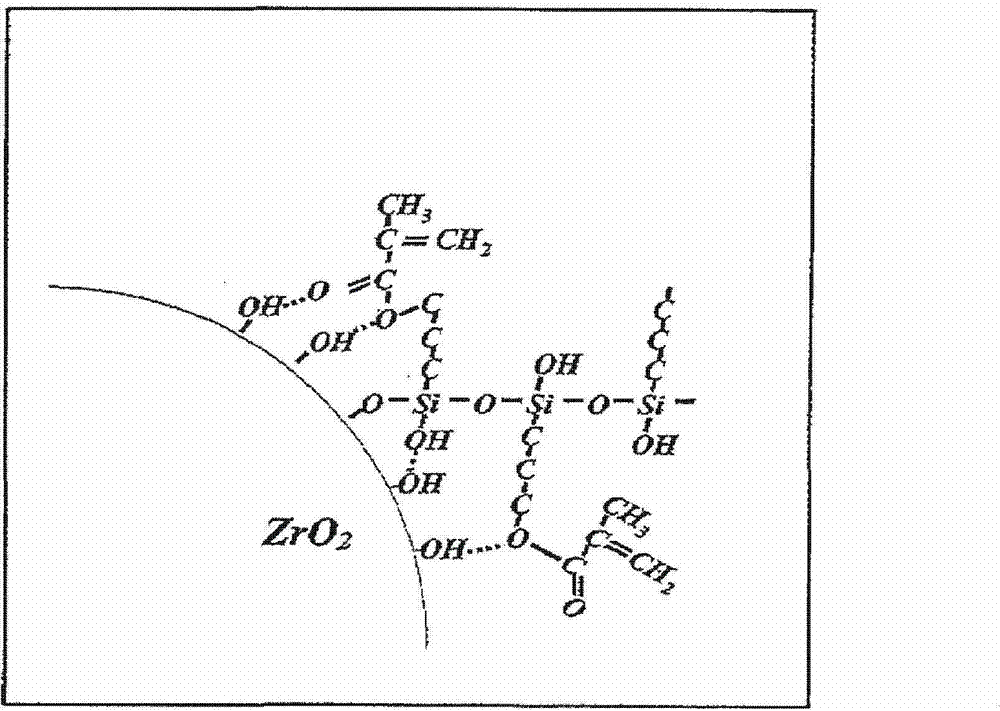

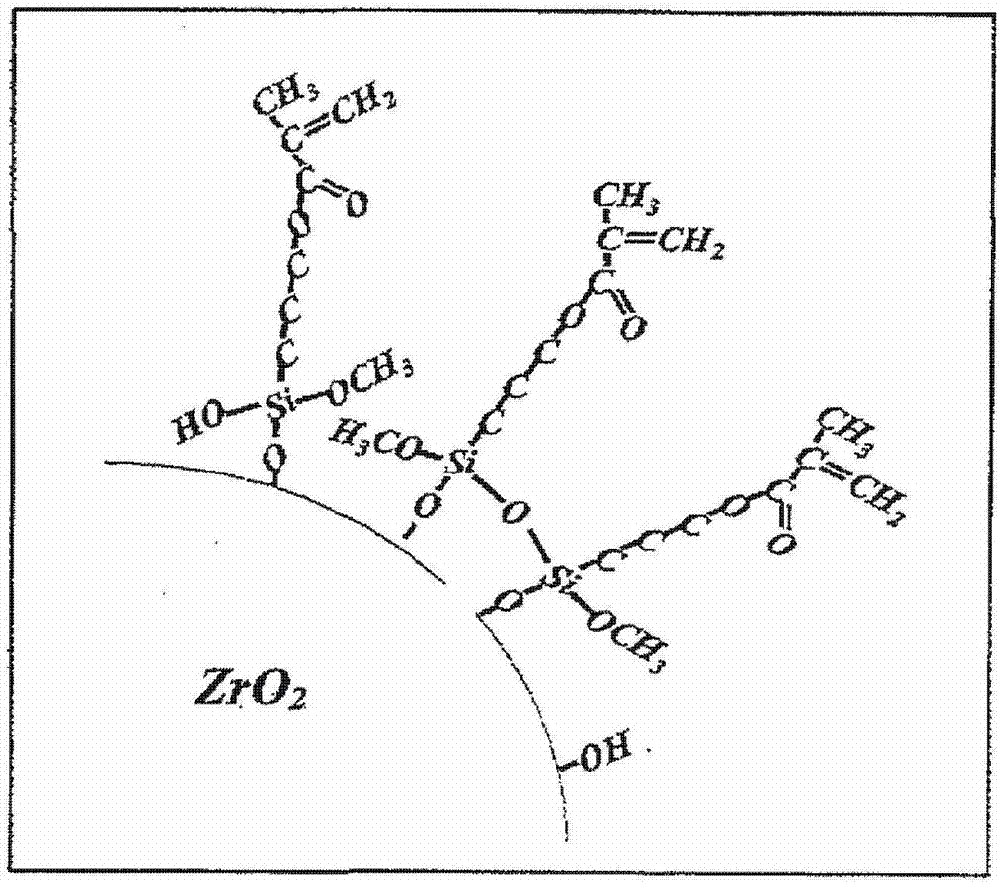

Method used

Image

Examples

preparation example Construction

[0108] Preparation method of zirconia particles

[0109] In the present invention, after (a) degumming or dissolving the zirconium hydroxide gel in the presence of potassium hydroxide and hydrogen peroxide, (b) performing hydrothermal treatment, and (c) washing, such oxidized Zirconium particles.

[0110]First, the zirconium hydroxide gel is debonded or dissolved in the presence of potassium hydroxide and hydrogen peroxide. The zirconium hydroxide gel is not particularly limited as long as it can be debonded or dissolved in the presence of potassium hydroxide and hydrogen peroxide. For example, a zirconium hydroxide gel obtained by hydrolyzing or neutralizing a zirconium compound (including zirconium oxide hydrate, zirconium hydroxide, etc.).

[0111] The zirconium compound can be exemplified by zirconium chloride (ZrCl 2 ), zirconium oxychloride (ZrOCl 2 ), zirconium nitrate, zirconium oxynitrate, zirconium sulfate, zirconium carbonate, zirconium acetate, etc., and zirc...

Embodiment 1

[0181] Preparation of modified zirconia particles (1) powder

[0182] 317.9 kg of zirconium hydroxide gel having a solid concentration of 9.5% by weight was suspended in 535.3 kg of water to prepare a zirconium hydroxide gel dispersion having a solid concentration of 3.5% by weight.

[0183] Next, 354.9 kg of a KOH aqueous solution with a concentration of 17 wt %, 302.0 kg of an aqueous hydrogen peroxide solution with a concentration of 35 wt %, and 88.5 kg of an aqueous solution of tartaric acid with a concentration of 10 wt % were added to the zirconium hydroxide gel dispersion with a solid content concentration of 3.5 wt %. kg, and stirred at 30° C. for 2 hours to debond the zirconium hydroxide gel. process (a)

[0184] At this time, (M OH ) / (M Zr ) is 20, (M PO ) / (M Zr ) is 10. Next, 88.5 kg of an aqueous solution of tartaric acid having a concentration of 10% by weight was added to the solution obtained by debonding the zirconium hydroxide gel, and hydrothermal ...

Embodiment 2

[0231] Preparation of modified zirconia particles (2) powder

[0232] In Example 1, a modified zirconia fine particle (2) powder was produced in the same manner except that the powder was dried at 40°C for 24 hours. Process (f)

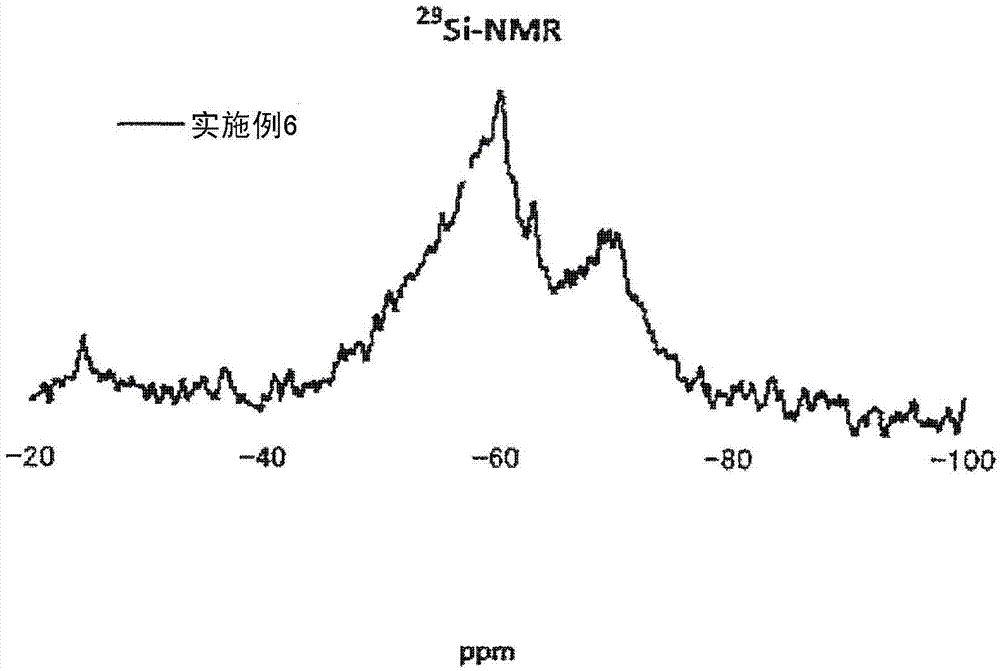

[0233] The obtained modified zirconia fine particle (2) powder was measured for moisture content, crystallinity, average particle diameter, angle of repose, and refractive index. Table 1 shows the results. also, 29 The chemical shift values and half widths of the main peaks of the SiMAS NMR spectrum are shown in the table.

[0234] Preparation of Modified Zirconia Particles (2) Organic Solvent Dispersion

[0235] In Example 1, a methanol dispersion of the modified zirconia fine particles (2) and the modified zirconia fine particles (2) having a solid content concentration of 30% by weight were obtained in the same manner except that the powder of the modified zirconia fine particles (2) was used. MIBK dispersion.

[0236] The average partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com