A method for preparing ni/p/nanometer sio2 ternary composite coating on the surface of pbo fiber

A ternary composite, fiber surface technology, applied in coating, liquid chemical plating, metal material coating process, etc., can solve the problems of molecular chain breakage, damage to mechanical properties, and impact on the durable use of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

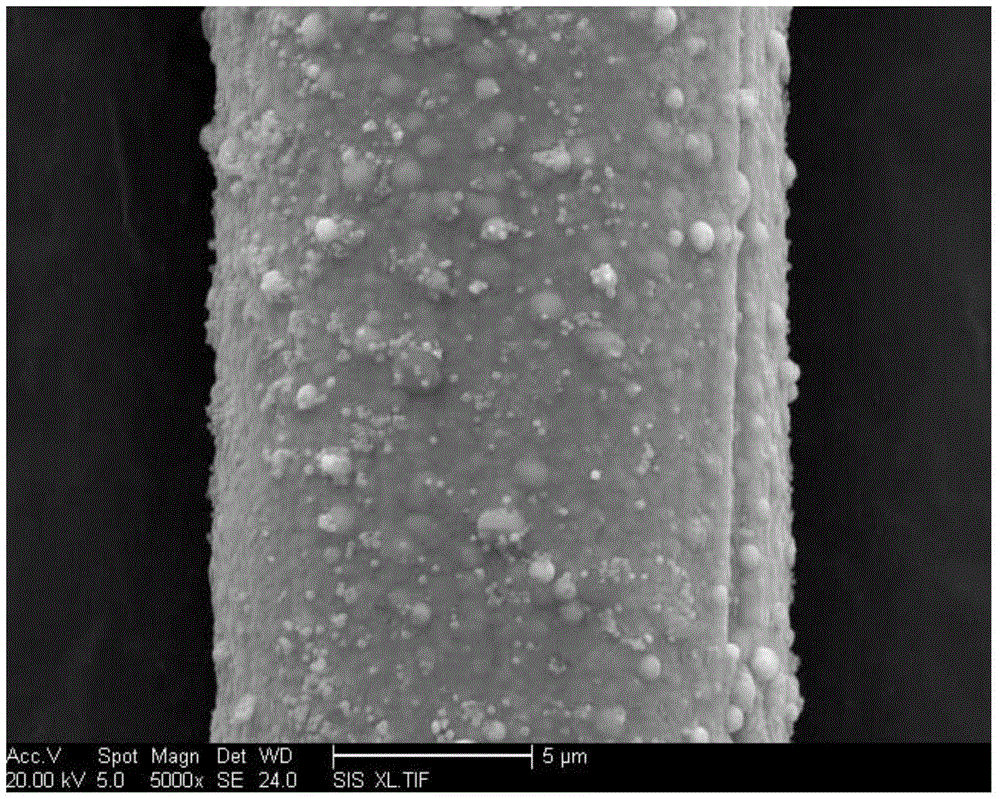

[0018] Specific embodiment 1: In this embodiment, a kind of Ni / P / nanometer SiO is prepared on the surface of PBO fiber 2 The method of ternary composite coating is carried out according to the following steps:

[0019] 1. Preparation of nano-SiO 2 Sol: Use a pipette to weigh 0.1mL-3mL deionized water and 2mL-9mL ammonia water and mix with 80mL-110mL absolute ethanol to obtain the mixed solution a. Turn on the constant temperature magnetic stirrer to stir and heat the mixed solution a at a speed of Stir at 200r / min~700r / min and temperature at 15℃~35℃, then quickly add 2mL~8mL orthosilicate ethyl ester dropwise, continue at temperature 15℃~35℃ and rotating speed at 200r / min~700r Stir continuously for 3h-7h under the condition of 1 / min to obtain SiO with a particle size of 50nm-200nm 2 Sol;

[0020] 2. PBO fiber coarsening treatment: Wrap the PBO fiber bundles on the U-shaped glass frame, and then vertically immerse the opening of the U-shaped glass frame wrapped with fibers i...

specific Embodiment approach 2

[0027] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the constant temperature magnetic stirrer is turned on to stir and heat so that the mixed liquid a has a rotating speed of 400r / min to 600r / min and a temperature of 20°C to 30°C. Stir under the condition of ℃, then quickly add 4mL~6mL orthosilicate ethyl ester dropwise, and continue to stir for 4h~6h at the temperature of 20℃~30℃ and the speed of 400r / min~600r / min to obtain the particle size 50nm ~ 200nm SiO 2 Sol. Others are the same as the first embodiment.

specific Embodiment approach 3

[0028] Specific embodiment three: the difference between this embodiment and one of specific embodiments one or two is: in step 2, use a magnetic stirrer to stir for 2h to 3h at room temperature and at a stirring speed of 200r / min to 250r / min, Take out the U-shaped glass frame wrapped with fibers, wash it with deionized water for 3 to 6 times, and finally dry it at a temperature of 100°C-120°C for 30min-40min to obtain a U-shaped glass wrapped with coarsened PBO fibers frame. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com