A kind of negative electrode of zinc-based battery and its preparation and application

A zinc-based battery, battery negative electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reduced Coulomb efficiency and cycle life, limited rapid development, battery structure damage, etc., to achieve no impurity interference and achieve effective control , The effect of uniform and dense deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Using the following steps to prepare:

[0038] (1) After the commercial carbon felt is washed with ethanol, acetone, and water, it is cleaned with ethanol, acetone, and water, as for 4 hours of vacuum ovens;

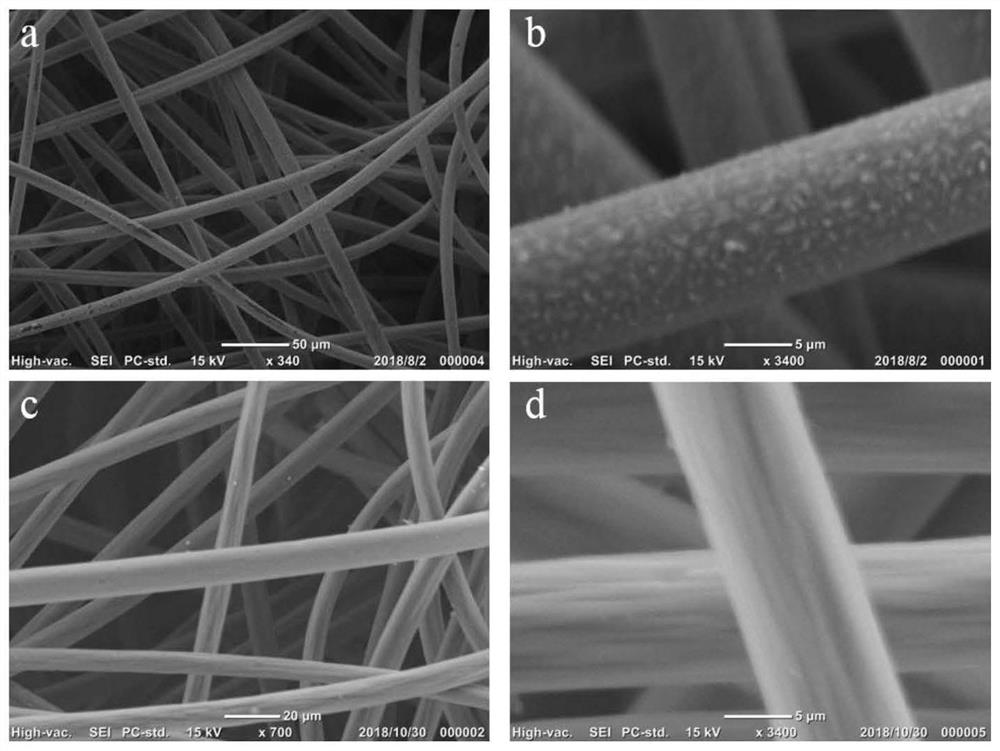

[0039] (2) The electrode substrate prepared by step (1) is on the sample table of the magnetron sputtering apparatus presented in advance, and the molecular pump draws the sputter main chamber to 1 × 10 by mechanical pump. -3 Pa; close the sample baffle, the sputter gas is argon, the flow control is 50sccm, the power is 10 W / cm 2 The pressure is maintained at 1 Pa, pre-sputtering for 10 minutes, after the glow and power is relatively stable, open the sample baffle, start sputtering to the electrode substrate, power control at 20W / cm 2 The sputtering gas is argon, and the flow control is at 50sccm, and the pressure is maintained at 1 Pa; and after the sputter is completed, the sample is taken out and can be used. Sputter thickness ~ 1 μm.

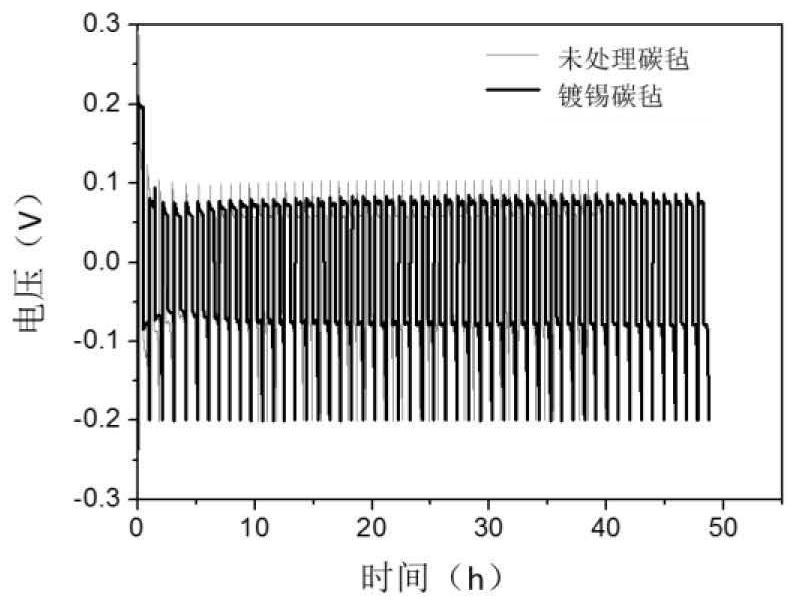

[0040] The carbon felt a...

Embodiment 2

[0043] Using the following steps to prepare:

[0044] (1) After the commercial carbon felt is washed with ethanol, acetone, and water, it is cleaned with ethanol, acetone, and water, as for 4 hours of vacuum ovens;

[0045] (2) The electrode substrate prepared by step (1) is on the sample table of the magnetron sputtering apparatus presented in advance, and the molecular pump draws the sputter main chamber to 1 × 10 by mechanical pump. -3 Pa; close the sample baffle, the sputter gas is argon, the flow control is 50sccm, the power is 10 W / cm 2 The pressure is maintained at 1 Pa, pre-sputtering for 10 minutes, after the glow and power is relatively stable, open the sample baffle, start sputtering to the electrode substrate, power control at 20W / cm 2 The sputtering gas is argon, and the flow control is at 50sccm, and the pressure is maintained at 1 Pa; and after the sputter is completed, the sample is taken out and can be used. The sputter thickness was ~ 5 nm.

[0046] The carbo...

Embodiment 3

[0049] Using the following steps to prepare:

[0050] (1) After the electrode substrate to be plated is washed with ethanol, acetone and water, as for vacuum oven 80 ° C, drying for 4 hours;

[0051] (2) The electrode substrate prepared by step (1) is on the sample table of the magnetron sputtering apparatus presented in advance, and the molecular pump draws the sputter main chamber to 1 × 10 by mechanical pump. -3 Pa; close the sample baffle, the sputter gas is argon, the flow control is 50sccm, the power is 10 W / cm 2 The pressure is maintained at 1 Pa, pre-sputtering for 10 minutes, after the glow and power is relatively stable, open the sample baffle, start sputtering to the electrode substrate, power control at 20W / cm 2 The sputtering gas is oxygen, and the flow control is at 50sccm, and the pressure is maintained at 1 Pa; and after the sputter is completed, the sample is taken out. The sputter thickness was ~ 1 μm.

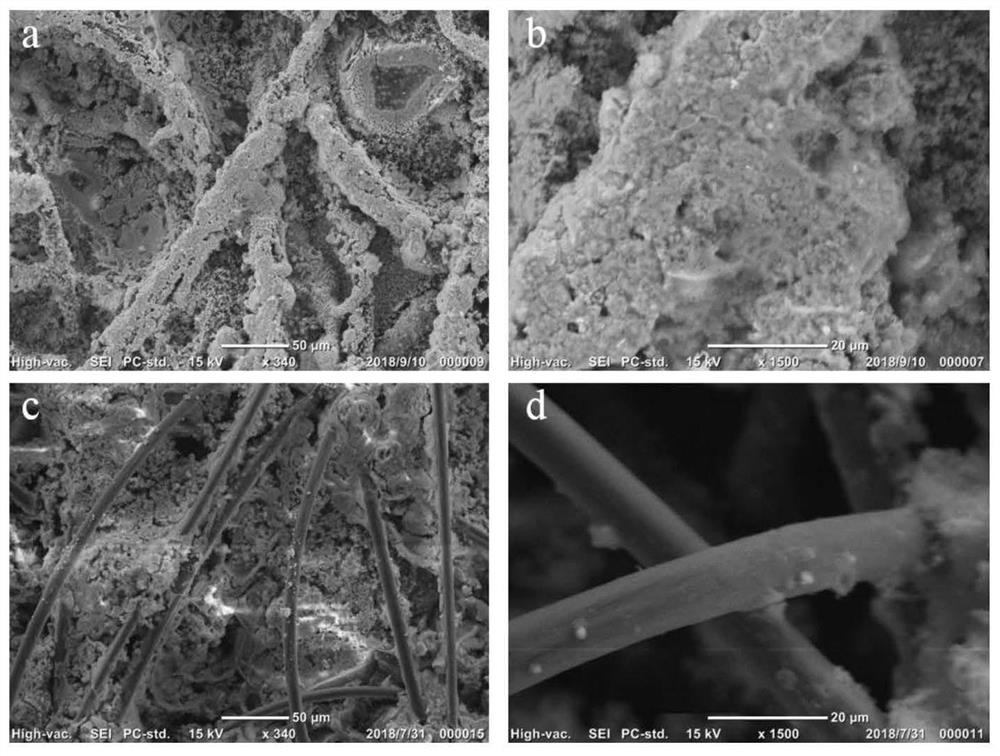

[0052] The carbon felt after magnetron sputtering is us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com