A method for preparing high-purity copper by electrowinning of scrap copper

A technology of high-purity copper and waste miscellaneous copper, which is applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of large consumption of ethylenediamine and failure to reduce power consumption, and achieve smooth surface, environmental friendliness, and deposition Uniform and dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

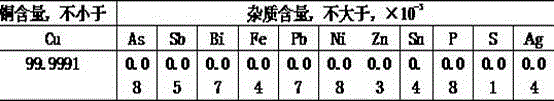

[0024] A kind of scrap miscellaneous copper, its chemical composition is as shown in table 1:

[0025] Table 1 The main chemical composition of scrap copper (%)

[0026] chemical composition Cu Zn Fe sn Bi Si Ag Pb As content 78.0 6.1 0.8 5.3 0.4 3.0 0.1 3.0 1.5

[0027]1) Dissolved copper: Weigh waste miscellaneous copper and place it in the reactor, add CuCl with a copper content of 80g / L 2 -NH 3 -NH 4 Cl solution, pH=10.0, dissolved at 30°C for 10 hours, filtered to obtain a filtrate with a copper content of 145g / L and a pH=9.4;

[0028] 2) Vacuum extraction: According to volume ratio = 30:20:48:2, add extractant kelex100, isooctyl alcohol, sulfonated kerosene and co-extractant P to the above filtrate 204 , ratio (O / W)=1:1, vacuum degree 0.02MPa, extraction time 60min, the extracted organic phase is re-extracted with hydrochloric acid to separate zinc, iron, nickel and other impurities, and then recycled, according to NH 3 -...

Embodiment 2

[0033] Scrap copper is identical with embodiment 1.

[0034] 1) Dissolving copper: Weigh waste miscellaneous copper and place it in the reactor, add CuCl with a copper content of 90g / L 2 -NH 3 -NH 4 Cl solution, pH=10.0, dissolved at 35°C for 10 hours, filtered to obtain a filtrate with a copper content of 165g / L and a pH=9.3;

[0035] 2) Vacuum extraction: According to volume ratio = 35:15:48.5:1.5, add extractant kelex100, isooctyl alcohol, sulfonated kerosene and co-extractant P to the above filtrate 204 , ratio (O / W)=1:2, vacuum degree 0.05MPa, extraction time 60min, the extracted organic phase is re-extracted with hydrochloric acid to separate impurities such as zinc, iron, nickel, and then recycled, according to NH 3 -NH 4 The volume ratio of Cl solution to raffinate is 5.6:1, with 350ml NH 3 / L and 35g / LNH 4 Cl NH 3 -NH 4 The Cl solution dilutes the raffinate so that the copper content is 25g / L and the pH is 9.80, and the raffinate enters the electrolytic cell a...

Embodiment 3

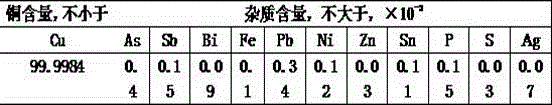

[0040] A kind of miscellaneous copper waste, its chemical composition is as shown in table 4.

[0041] Table 4 The main chemical composition (%) of scrap copper.

[0042] chemical composition Cu Zn Fe sn Bi Si Ag Pb As content 81.0 6.5 0.5 3.8 0.4 2.8 0.1 2.5 1.0

[0043] 1) Dissolved copper: Weigh waste miscellaneous copper and place it in the reactor, add CuCl with a copper content of 100g / L 2 -NH 3 -NH 4 Cl solution, pH=10.0, dissolved at 30°C for 10 hours, filtered to obtain a filtrate with a copper content of 172g / L and a pH=9.5;

[0044] 2) Vacuum extraction: According to volume ratio = 25:15:58:2, add extractant kelex100, isooctyl alcohol, sulfonated kerosene and co-extractant P to the above filtrate 204 , ratio (O / W)=1:1, vacuum degree 0.04MPa, extraction time 60min, the extracted organic phase is re-extracted with hydrochloric acid to separate impurities such as zinc, iron, nickel, and then recycled, according to NH 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com