Low-temperature electrolyte of lithium iron phosphate battery

A lithium iron phosphate battery and electrolyte technology, applied in the fields of material chemistry and electrochemistry, can solve the problems of easy generation of acidic impurities and poor electrical conductivity, achieve good normal temperature charge and discharge, ensure electrical conductivity, and reduce low-temperature charge transfer impedance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

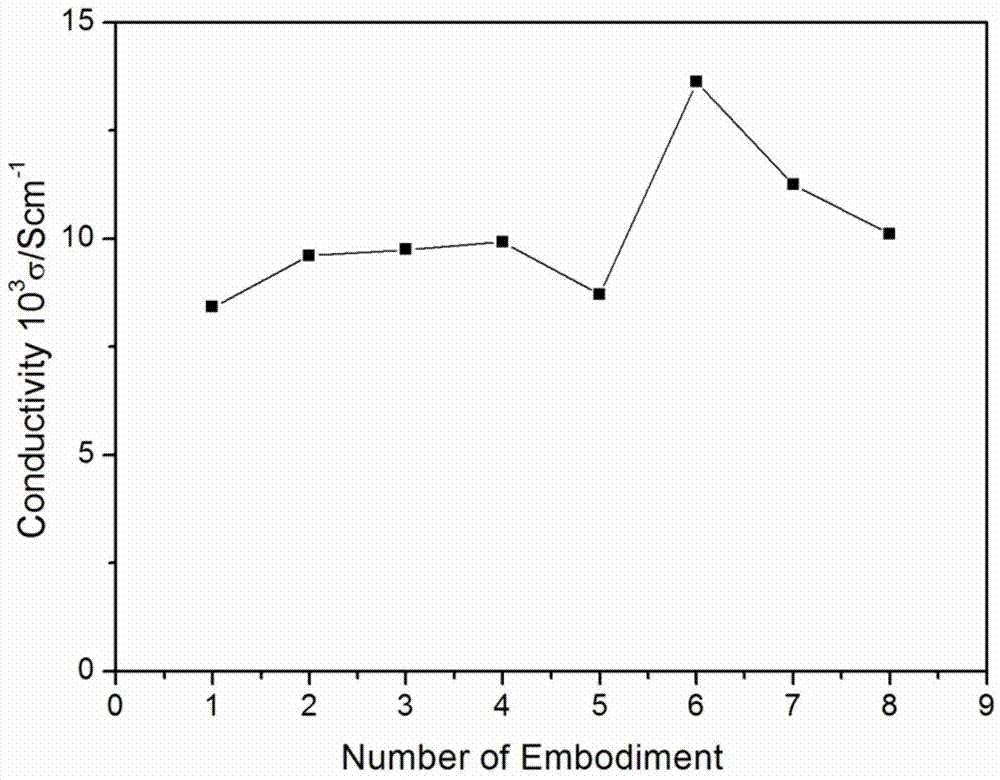

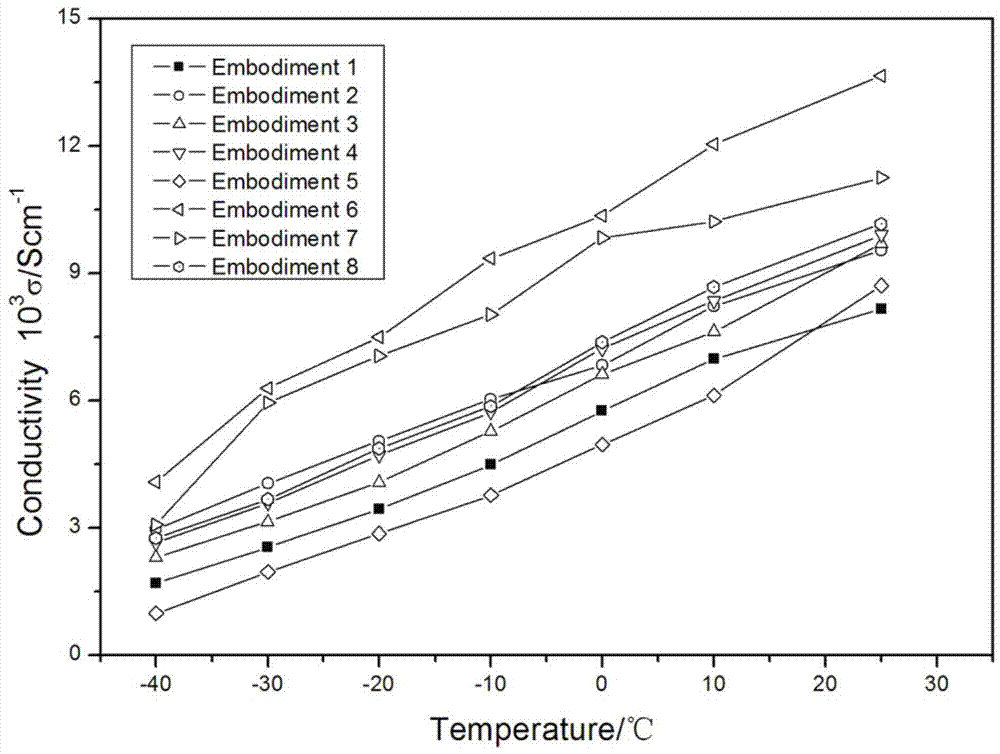

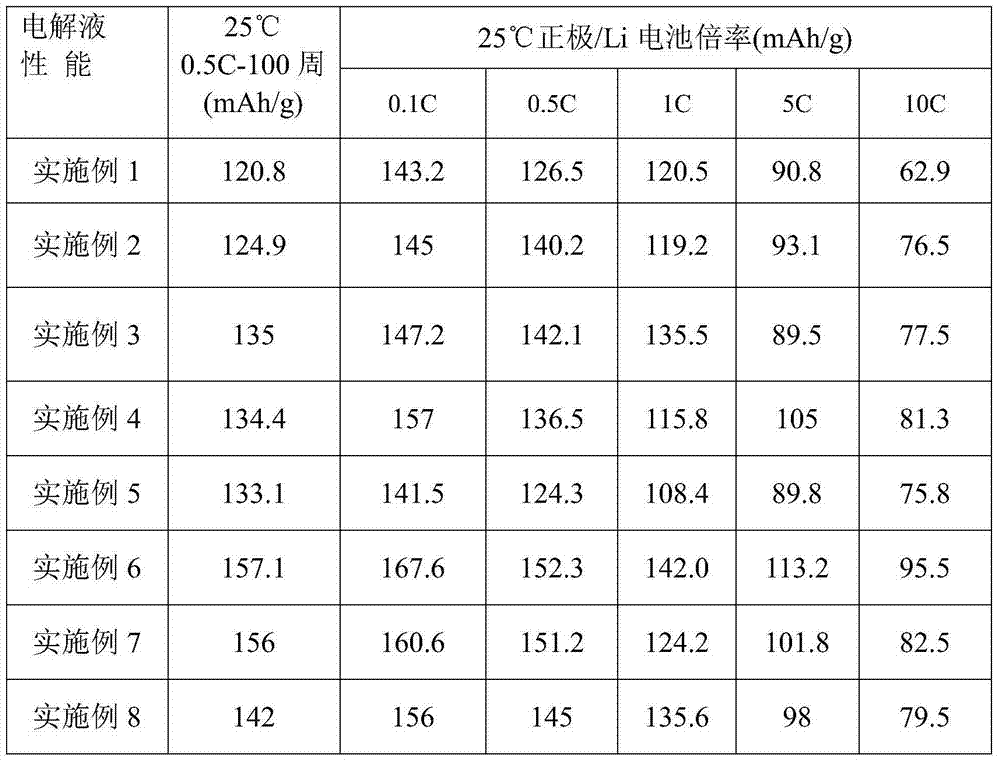

Embodiment 1

[0032] Take 10% ethylene carbonate, 35% ethyl methyl carbonate, 25% methyl formate and 25% ethyl butyrate according to volume percentage, stir and mix evenly in a glove box with humidity less than 10ppm, while the solution temperature Controlled at 25°C, configured as a solvent for the electrolyte; then add 1mol / L lithium salt LiPF in portions 6 After the electrolyte is completely dissolved, add 5% vinylene carbonate and 5% propylene sulfite. After the electrolyte was left to stand for 24 hours, the low-temperature electrolyte of the lithium iron phosphate battery of this embodiment was obtained.

Embodiment 2

[0034] Take 10% methyl propyl fluorocarbonate, 20% ethyl methyl carbonate, 25% methyl formate and 36% methyl butyrate according to volume percentage, stir and mix evenly in a glove box with humidity less than 10ppm, At the same time, the temperature of the solution is controlled at 25°C, and it is configured as a solvent for the electrolyte; then 1mol / L lithium salt LiPF is added in portions 6 , After the electrolyte is completely dissolved, add 5% vinylene carbonate and 4% propylene sulfite as additives. After the electrolyte was left to stand for 24 hours, the low-temperature electrolyte of the lithium iron phosphate battery of this embodiment was obtained.

Embodiment 3

[0036] Take 10% methyl propyl fluorocarbonate, 20% ethyl methyl carbonate, 25% methyl acetate and 36% methyl propionate respectively according to volume percentage, stir and mix evenly in a glove box with humidity less than 10ppm, At the same time, the temperature of the solution is controlled at 25°C, and it is configured as a solvent for the electrolyte; then 0.8mol / L lithium salt LiPF is added in portions 6 , 0.11mol / L LiBF 4 , After the electrolyte is completely dissolved, add 5% vinylene carbonate and 4% propylene sulfite as additives. After the electrolyte was left to stand for 24 hours, the low-temperature electrolyte of the lithium iron phosphate battery of this embodiment was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com