A kind of zinc ion battery electrolyte modifier and its preparation method and application

A zinc-ion battery, electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of poor battery life, aggravated dendrite growth, etc., achieve low cost, reduce corrosion and passivation, and can size control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In one embodiment of the present disclosure, a method for preparing an electrolyte modifier for a zinc-ion battery includes: two-dimensional MXene colloidal solution is obtained by etching and stripping with mild fluoride and acid etchant, TiO 2 The nanosheets are obtained by oxidizing the two-dimensional MXene colloidal solution with a hydrothermal method.

[0028] In one embodiment of the present disclosure, a method for preparing an electrolyte modifier for a zinc ion battery specifically includes:

[0029] Preparation of two-dimensional MXene colloidal solution: Stir the powder of the MAX phase in a mixed solution of acid and fluoride, then add water and centrifuge to remove excess acid and fluoride, and then peel off the multilayer MXene by ultrasonic stripping or adding a layering reagent and centrifuging , the monolayer / less layered MXene colloidal solution obtained by separation;

[0030] Preparation of high safety and long life zinc ion battery electrolyte mod...

Embodiment 1

[0050] A zinc ion battery electrolyte modifier, the preparation method is as follows:

[0051] Weighing Ti in MAX phase 3 AlC 2 0.8g powder, dissolved in a mixed solution of hydrochloric acid and lithium fluoride and stirred, then added water and centrifuged to remove excess acid and fluoride, and then centrifuged at 2000r / min to peel off multi-layer MXene, and the obtained monolayer / less layer of MXene colloidal solution;

[0052] Then, 50ml of MXene colloidal solution was heated at 200°C for 48 hours, centrifuged to take the bottom solid, vacuum dried in a vacuum oven at 60°C, and ground to obtain TiO 2 Nanosheet Modifier.

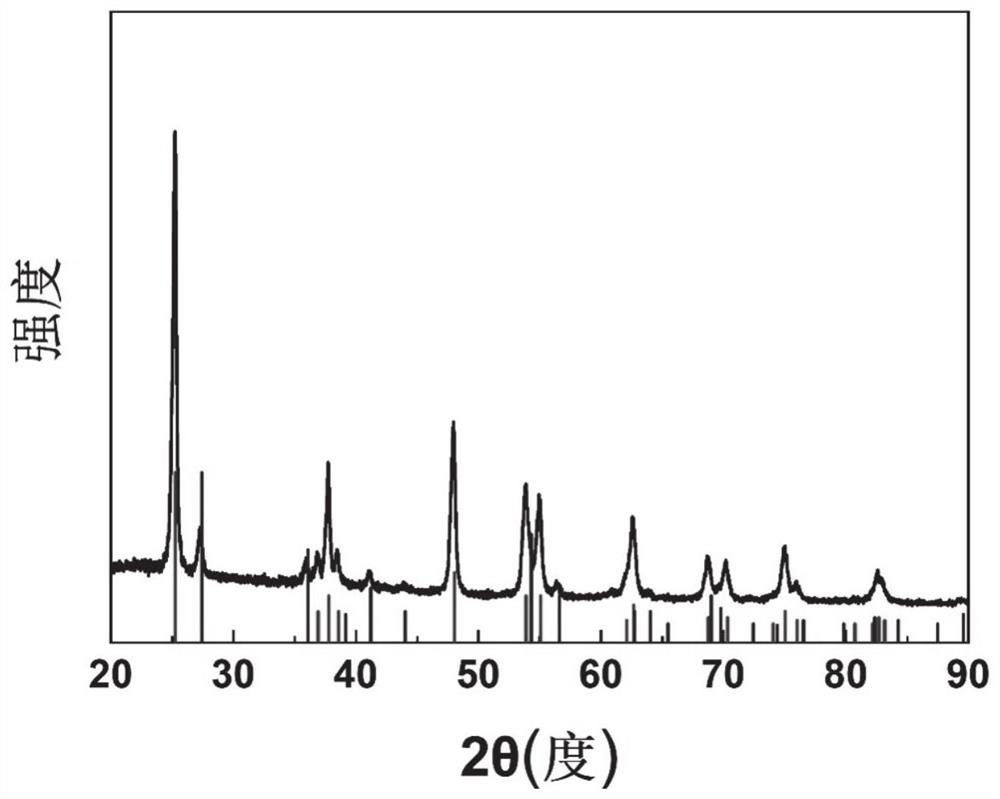

[0053] Such as figure 1 Shown, TiO 2 The characteristic peaks of nanosheets correspond to PDF cards 21-1272 and 21-1276, which are mixed phases of spinel and anatase. TiO 2 It can induce the uniform distribution of the electric field on the surface of the zinc metal, effectively suppress the tip effect on the surface of the zinc negative electrode...

Embodiment 2

[0056] A zinc ion battery electrolyte modifier, the preparation method is as follows:

[0057] Weighing Ti in MAX phase 3 AlC 2 0.8g powder, dissolved in a mixed solution of hydrochloric acid and lithium fluoride and stirred, then added water and centrifuged to remove excess acid and fluoride, and then centrifuged at 2000r / min to peel off multi-layer MXene, and the obtained monolayer / less layer of MXene colloidal solution;

[0058] Then, heat 100ml of MXene colloidal solution at 150°C for 24 hours, centrifuge to get the bottom solid, vacuum dry in a vacuum oven at 80°C, and grind to obtain TiO 2 Nanosheet Modifier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com