Neutral zinc-iron liquid flow battery of food-grade electrolyte

A flow battery, food-grade technology, used in fuel cells, acidic electrolytes, aqueous electrolytes, etc., can solve problems such as irritation to eyes and respiratory tract, environmental and biological toxicity, biological damage, etc., to improve cycle stability and cost. Low, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

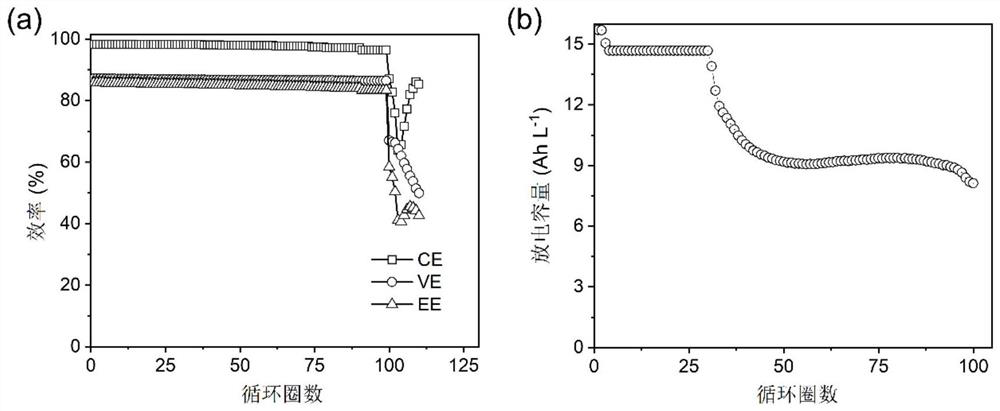

[0038] The composition of positive electrode electrolyte is 1mol L -1 Ferrous gluconate+2mol L -1 NaCl; negative electrode electrolyte composition is 0.5mol L -1 Zinc gluconate+2mol L -1 NaCl; the separator is a polybenzimidazole porous ion-conducting membrane; at 40mA cm -2 Charge for 35min under the current density condition, take the capacity cut-off as the cut-off condition, and then charge at 40mA cm -2 Discharge to 0.1V under the condition of current density. It can be seen from the efficiency curve in the figure that the CE, VE and EE of the battery are 99.3%, 86.5%, and 85.6%, respectively. From Figure 5 a It can be seen that the neutral zinc-iron flow battery using ferrous gluconate as the active material in the positive electrode has no significant change in battery performance within 150 cycles. The corresponding battery runs continuously and stably for 150 cycles, and the battery capacity ( Figure 5 b) maintained well, exhibiting excellent cycle stability....

Embodiment 2

[0040] Embodiment 2 (performance under different current densities)

[0041] The composition of positive electrode electrolyte is 1mol L -1 Ferrous gluconate+2mol L -1 NaCl; negative electrode electrolyte composition is 0.5mol L -1 Zinc gluconate+2mol L -1 NaCl, the positive and negative electrolyte volumes are 60mL each; the diaphragm is a polybenzimidazole porous ion-conducting membrane; then at 40mA cm -2 , 60mA cm -2 , 80mA cm -2 , 100mA cm -2 The current density conditions were charged for 35min, 23.3min, 17.5min, and 14min, respectively, and then discharged to 0.1V at the corresponding current density. Depend on Figure 6 It can be seen that the modified neutral zinc-iron flow battery has better performance at different current densities, which proves that the battery can operate stably at different current densities.

Embodiment 3

[0042] Embodiment 3 (performance under different temperatures)

[0043] The composition of positive electrode electrolyte is 1mol L -1 Ferrous gluconate+2mol L -1 NaCl; negative electrode electrolyte composition is 0.5mol L -1 Zinc gluconate+2mol L -1 NaCl, the positive and negative electrolyte volumes are 60mL each; the diaphragm is a polybenzimidazole porous ion-conducting membrane; at 40mA cm -2 Charge for 35min under the current density condition, take the capacity cut-off as the cut-off condition, and then charge at 40mA cm -2 Discharge to 0.1V under the condition of current density. Operating at 25°C, 35°C, 45°C, and 55°C respectively, the performance of the battery is shown in the figure. Depend on Figure 7 It can be seen that the battery has good performance at different temperatures, which indicates that the battery can operate stably at different temperatures.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com