Titanium aluminum silver nitrogen nanocomposite coating and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

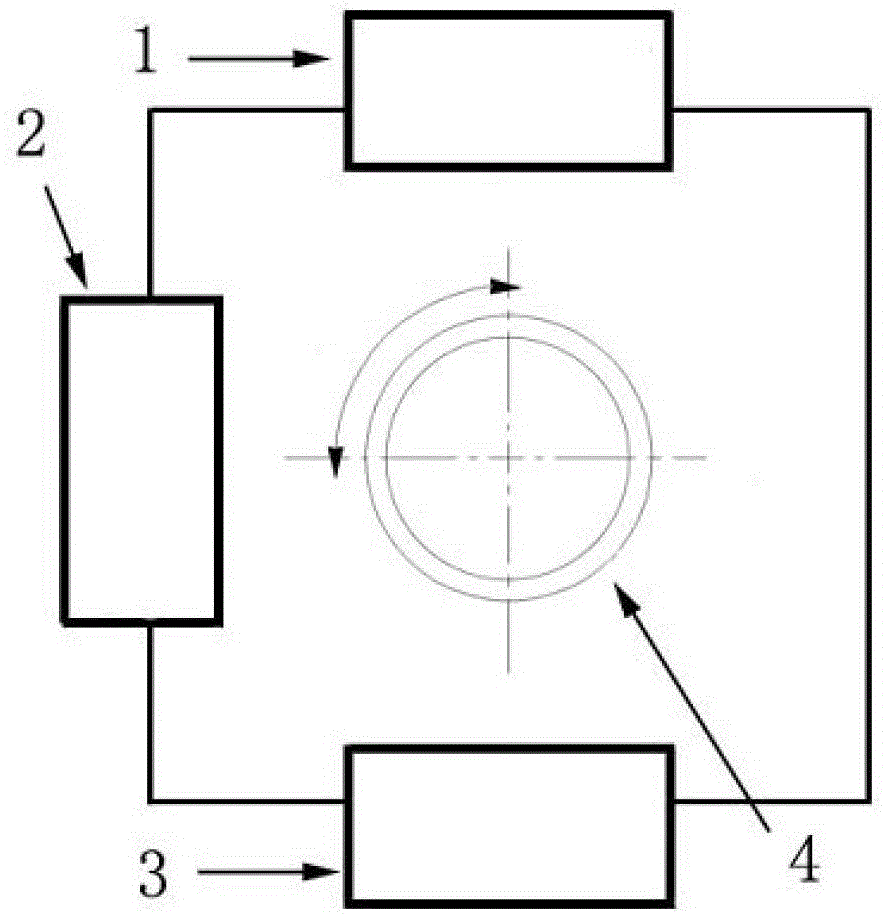

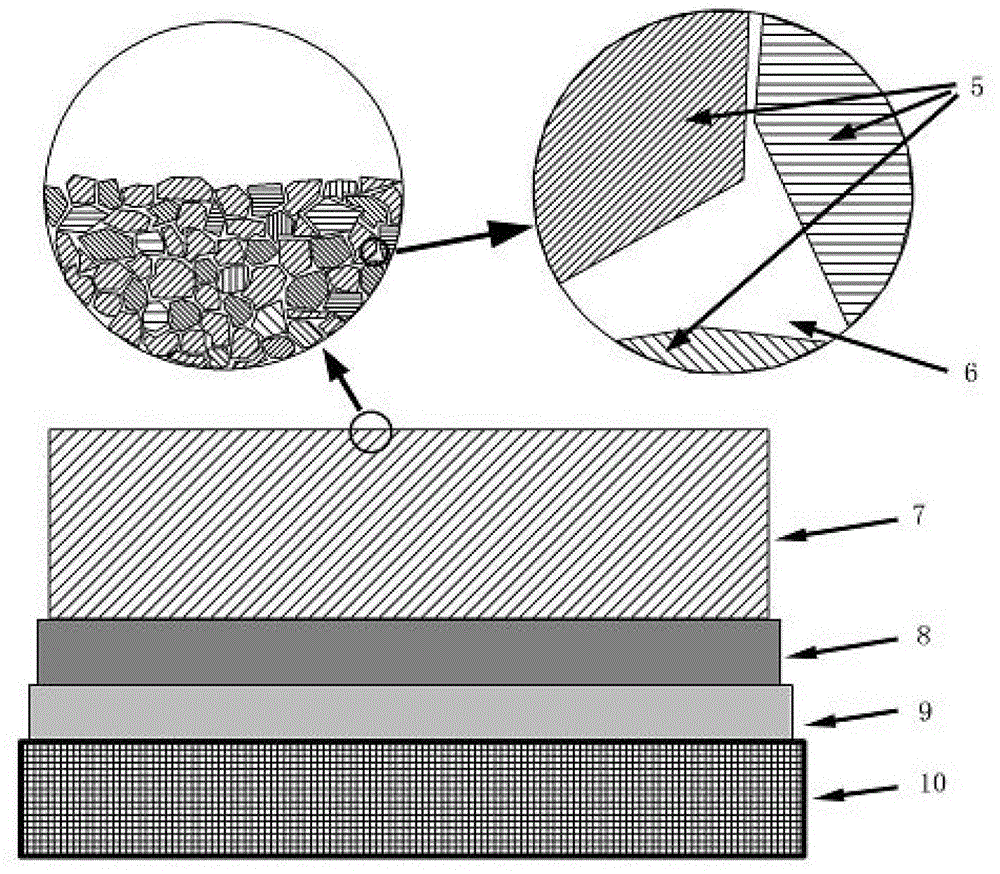

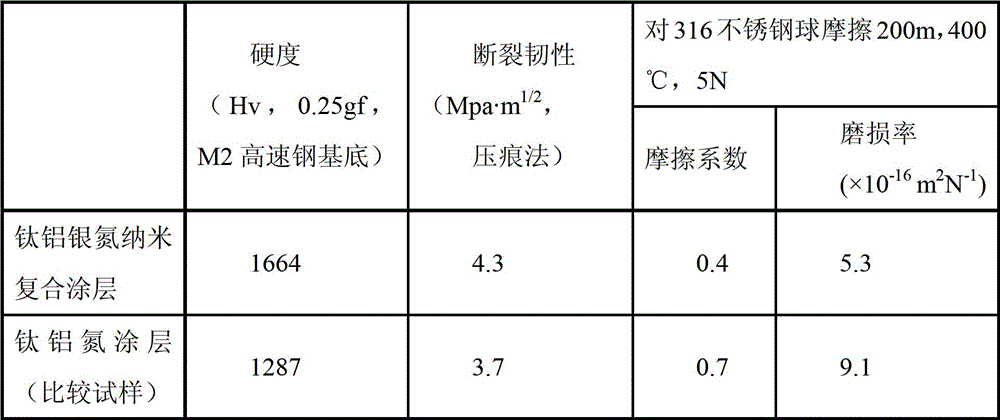

specific Embodiment 1

[0042] A titanium-aluminum-silver-nitrogen nanocomposite coating, which adopts a magnetron sputtering deposition method, includes the following implementation steps: step 1, put the metal or alloy substrate into the cavity of the coating equipment and then evacuate to 2.5×10 -3 Pa, then turn on the heating power supply to heat the metal or alloy substrate to 350°C and stabilize it, and then use a mass flow meter to controllably feed Ar (argon gas) into the vacuum chamber of the coating equipment to maintain a vacuum pressure of 0.25Pa; Step 2 , set the sample stage to start rotating at an angular speed of 5 rpm, and turn on the base bias voltage to 500V, then turn on the chromium target starter power supply at 0.03A / dm 2 The current density of sputtering for 30min; then within 5min, the bias voltage is linearly reduced to 45V according to time, and the current density of the chromium target is linearly increased to 2A / dm within 5min. 2 , and keep it for 10min; step 3, use a ma...

specific Embodiment 2

[0047] A titanium-aluminum-silver-nitrogen nanocomposite coating, which adopts a magnetron sputtering deposition method, includes the following implementation steps: step 1, put the metal or alloy substrate into the cavity of the coating equipment and then evacuate to 2.5×10 -3 Pa, then turn on the heating power supply to heat the metal or alloy substrate to 400°C and stabilize it, and then use a mass flow meter to controllably feed Ar (argon gas) into the vacuum chamber of the coating equipment to maintain a vacuum pressure of 0.25Pa; Step 2 , set the sample stage to start rotating at an angular speed of 5 rpm, and turn on the base bias voltage to 500V, then turn on the chromium target starter power supply at 0.03A / dm 2 The current density of sputtering for 30min; then within 5min, the bias voltage is linearly reduced to 45V according to time, and the current density of the chromium target is linearly increased to 2A / dm within 5min. 2 , and keep it for 20min; step 3, use a ma...

specific Embodiment 3

[0052] A titanium-aluminum-silver-nitrogen nanocomposite coating, which adopts a magnetron sputtering deposition method, includes the following implementation steps: step 1, put the metal or alloy substrate into the cavity of the coating equipment and then evacuate to 2.5×10 -3 Pa, then turn on the heating power supply to heat the metal or alloy substrate to 450°C and stabilize it, and then use a mass flow meter to controllably feed Ar (argon gas) into the vacuum chamber of the coating equipment to maintain a vacuum pressure of 0.25Pa; Step 2 , set the sample stage to start rotating at an angular speed of 5 rpm, and turn on the base bias voltage to 500V, then turn on the chromium target starter power supply at 0.03A / dm 2 The current density of sputtering for 30min; then within 5min, the bias voltage is linearly reduced to 45V according to time, and the current density of the chromium target is linearly increased to 2A / dm within 5min. 2 , and keep it for 20min; step 3, use a ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com