Titanium-aluminum-silver-nitride nano composite coating and preparation method thereof

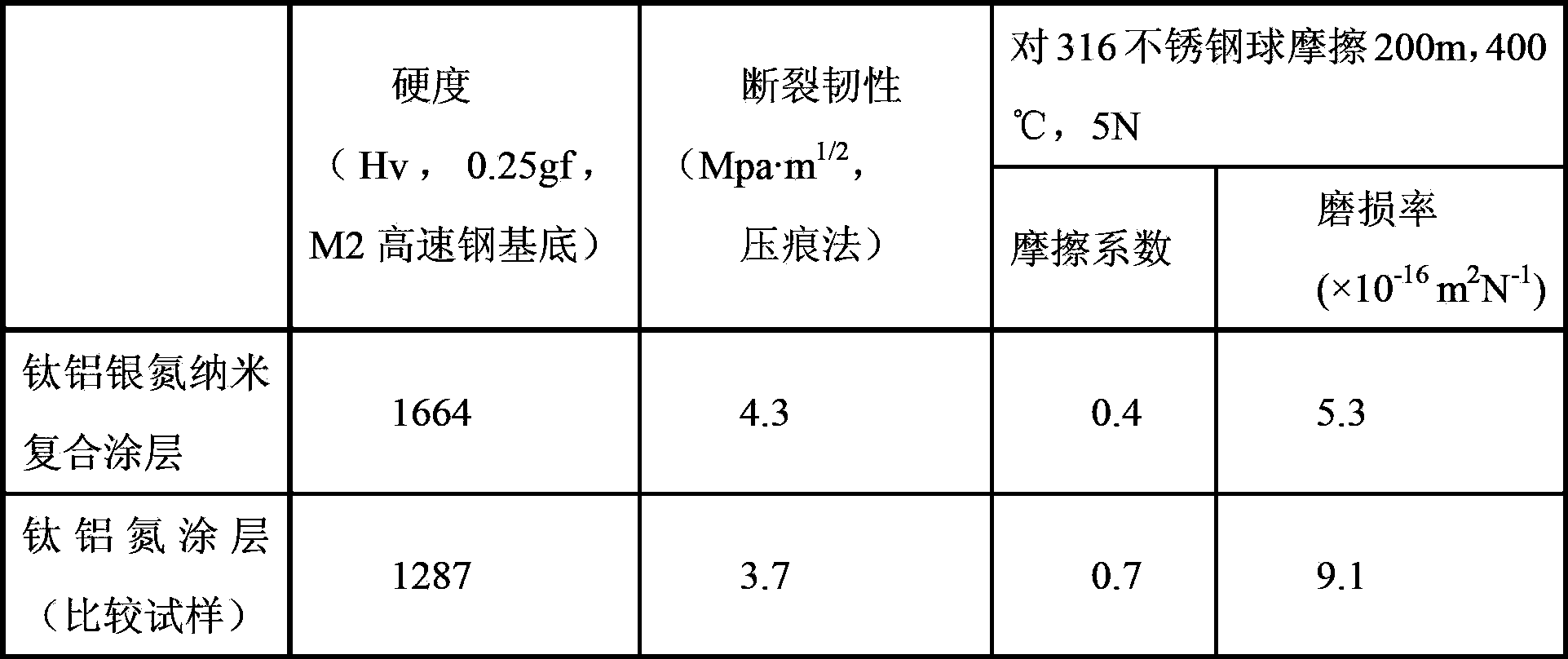

A nano-composite coating, titanium-aluminum-nitrogen technology, applied in the coating, metal material coating process, ion implantation plating and other directions, can solve the problem of interface modulation can not improve wear resistance, low, etc., to suppress excessive wear, Maintaining high hardness and relieving frictional heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

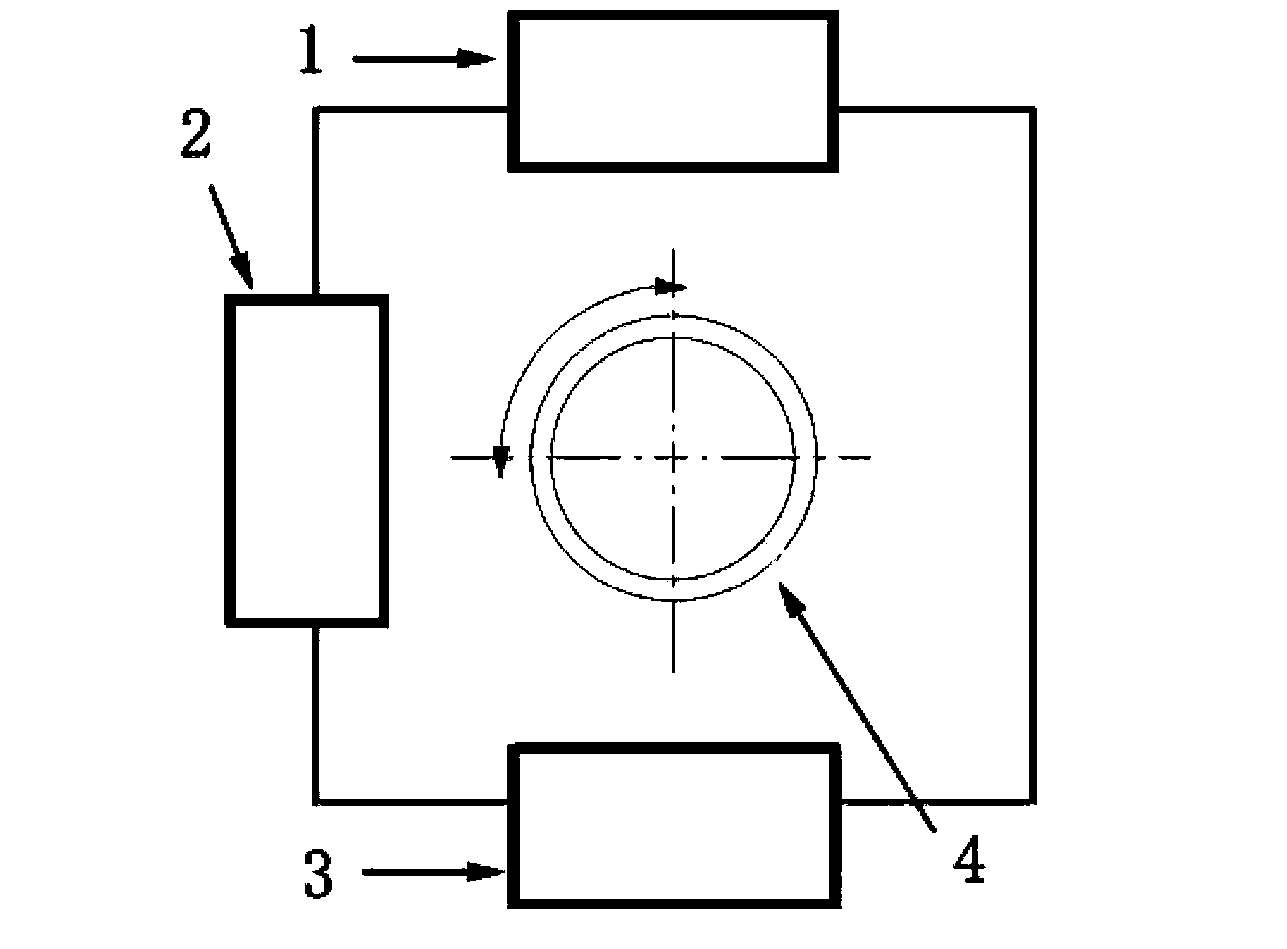

Method used

Image

Examples

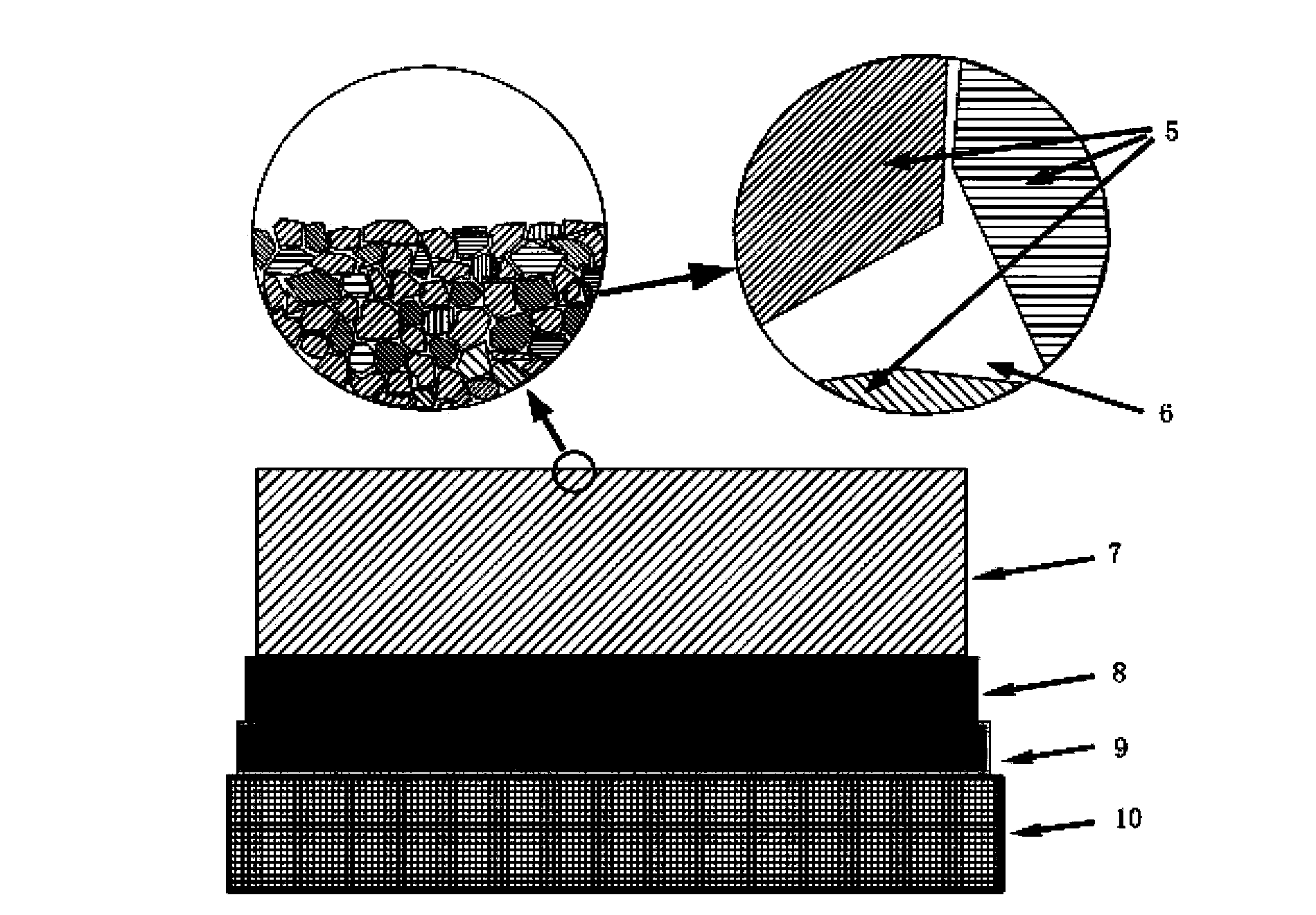

specific Embodiment 1

[0042] A titanium-aluminum-silver-nitrogen nanocomposite coating, which adopts a magnetron sputtering deposition method, includes the following implementation steps: step 1, put the metal or alloy substrate into the cavity of the coating equipment and then evacuate to 2.5×10 -3 Pa, then turn on the heating power supply to heat the metal or alloy substrate to 350°C and stabilize it, and then use a mass flow meter to controllably feed Ar (argon gas) into the vacuum chamber of the coating equipment to maintain a vacuum pressure of 0.25Pa; Step 2 , set the sample stage to start rotating at an angular speed of 5 rpm, and turn on the base bias voltage to 500V, then turn on the chromium target starter power supply at 0.03A / dm 2 The current density of sputtering for 30min; then within 5min, the bias voltage is linearly reduced to 45V according to time, and the current density of the chromium target is linearly increased to 2A / dm within 5min. 2 , and keep it for 10min; step 3, use a ma...

specific Embodiment 2

[0047] A titanium-aluminum-silver-nitrogen nanocomposite coating, which adopts a magnetron sputtering deposition method, includes the following implementation steps: step 1, put the metal or alloy substrate into the cavity of the coating equipment and then evacuate to 2.5×10 -3 Pa, then turn on the heating power supply to heat the metal or alloy substrate to 400°C and stabilize it, and then use a mass flow meter to controllably feed Ar (argon gas) into the vacuum chamber of the coating equipment to maintain a vacuum pressure of 0.25Pa; Step 2 , set the sample stage to start rotating at an angular speed of 5 rpm, and turn on the base bias voltage to 500V, then turn on the chromium target starter power supply at 0.03A / dm 2 The current density of sputtering for 30min; then within 5min, the bias voltage is linearly reduced to 45V according to time, and the current density of the chromium target is linearly increased to 2A / dm within 5min. 2 , and keep it for 20min; step 3, use a ma...

specific Embodiment 3

[0052] A titanium-aluminum-silver-nitrogen nanocomposite coating, which adopts a magnetron sputtering deposition method, includes the following implementation steps: step 1, put the metal or alloy substrate into the cavity of the coating equipment and then evacuate to 2.5×10 -3 Pa, then turn on the heating power supply to heat the metal or alloy substrate to 450°C and stabilize it, and then use a mass flow meter to controllably feed Ar (argon gas) into the vacuum chamber of the coating equipment to maintain a vacuum pressure of 0.25Pa; Step 2 , set the sample stage to start rotating at an angular speed of 5 rpm, and turn on the base bias voltage to 500V, then turn on the chromium target starter power supply at 0.03A / dm 2 The current density of sputtering for 30min; then within 5min, the bias voltage is linearly reduced to 45V according to time, and the current density of the chromium target is linearly increased to 2A / dm within 5min. 2 , and keep it for 20min; step 3, use a ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com