Preparation method of three-dimensional dendritic TiO2 (titanium dioxide) array with rapid electronic transmission performance

A technology with three-dimensional dendrites and transmission properties, applied in the direction of titanium dioxide, titanium oxide/hydroxide, circuits, etc., can solve the problems of reducing electron transmission rate and difficult crystal growth, and achieve the effect of improving battery efficiency and short-circuit current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In a more typical embodiment of the present invention, the three-dimensional dendritic TiO with fast electron transport properties 2 The preparation method of the array may include the following steps:

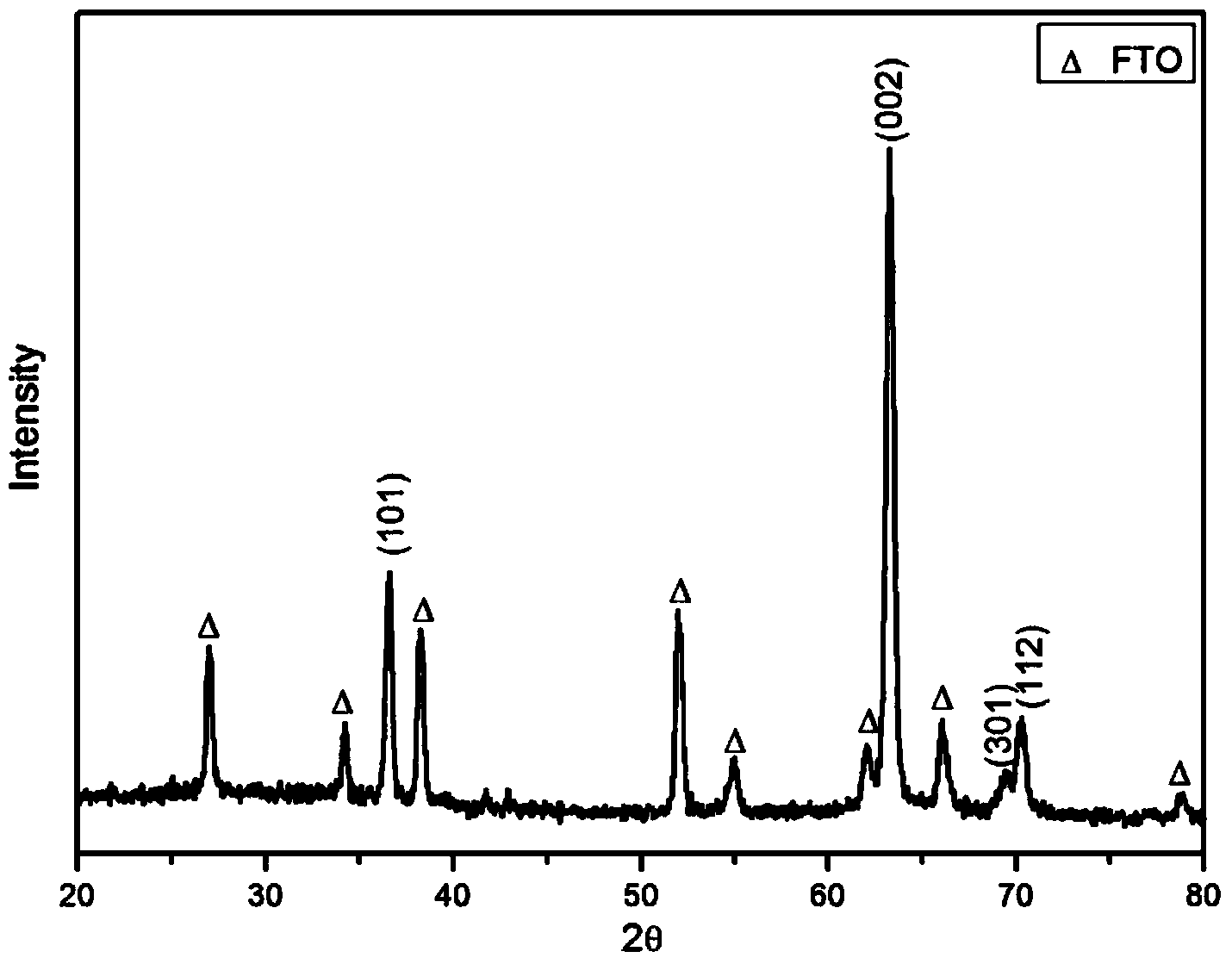

[0036] (1) Deposit TiO on the cleaned transparent conductive glass by dipping and pulling method 2 For the seed layer, the sol used is a tetrabutyl titanate ethanol solution with a concentration of 0.4 M, and then sintered in an air atmosphere.

[0037] Preferably, the transparent conductive glass used is fluorine-doped tin oxide (FTO) glass, the pulling rate is 100 mm / s, and the sintering temperature is 550o C, the sintering time is 30 min.

[0038] (2) Preparation of one-dimensional TiO by solvothermal method 2 array, put the cleaned transparent conductive glass deposited with the seed layer obtained in step (1) into a high-pressure reactor, and then add a certain proportion of Ti-containing reactants, hydrochloric acid and ketone solvents, and keep it at a certain ...

Embodiment 1

[0048] TiO will be deposited 2 The FTO glass of the seed layer was placed in an autoclave, and 6 mL of hydrochloric acid (37wt%), 6 mL of 2-butanone and 0.4 mL of tetrabutyl titanate were added, at 200 o C for 60 min, after cooling, the sample was taken out, rinsed with ethanol, soaked in a mixed solution of hydrogen peroxide and ammonia with a volume ratio of 10:1 for 10 min, and rinsed with deionized water. Put the processed sample into the reaction vessel, add 0.1 mL of titanium trichloride hydrochloric acid solution (20wt% titanium trichloride dissolved in 2M hydrochloric acid), 0.2 mL of hydrochloric acid (37wt%) and 10 mL of deionized water, at 80 o C for 90 min, after cooling, the samples were taken out, rinsed with deionized water, and then processed in an oxygen plasma cleaner with an oxygen flow rate of 0.6 L / min, with a power of 50 W and a processing time of 10 min. Finally, the sample was placed in an oxygen atmosphere with an oxygen flow rate of 0.5 L / min for 45...

Embodiment 2

[0051] TiO will be deposited 2 The FTO glass of the seed layer was placed in an autoclave, and 6 mL of hydrochloric acid (37wt%), 6 mL of pentanone, and 0.6 mL of tetrabutyl titanate were added to the autoclave at 200 o C for 50 min, after cooling, the sample was taken out, rinsed with ethanol, soaked in a mixed solution of hydrogen peroxide and ammonia at a volume ratio of 10:1 for 10 min, and rinsed with deionized water. Put the processed sample into the reaction vessel, add 0.05 mL of titanium trichloride hydrochloric acid solution (20wt% titanium trichloride dissolved in 2M hydrochloric acid), 0.1 mL of hydrochloric acid (37wt%), and 10 mL of deionized water, at 100 o C for 120 min, after cooling, the samples were taken out, rinsed with deionized water, and then processed in an oxygen plasma cleaner with an oxygen flow rate of 1 L / min, with a power of 50 W and a processing time of 10 min. Finally, the sample was placed in an oxygen atmosphere with an oxygen flow rate of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com