Polyformaldehyde product and preparation method thereof

A technology of polyoxymethylene and products, applied in the coating and other directions, can solve the problems of poor adhesion on the surface of polyoxymethylene, and achieve the effects of improving the characteristics that are not easy to spray, improving adhesion and easy spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

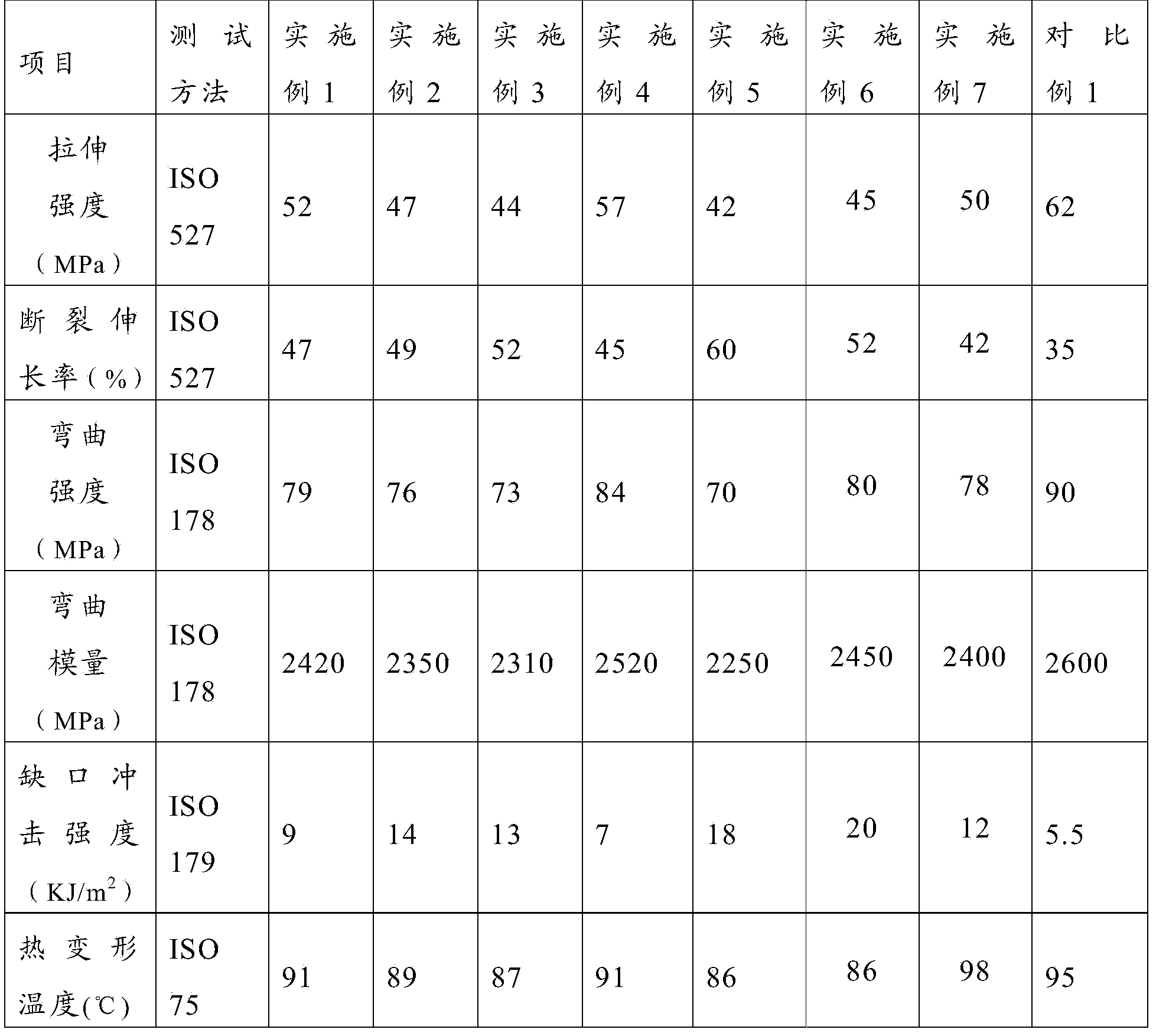

Examples

preparation example Construction

[0025] The embodiment of the present invention discloses a preparation method of a polyoxymethylene product, comprising the following steps:

[0026] (A) Mix 60-88wt% polyoxymethylene powder, 10-38wt% soluble material, 1-5wt% compatibilizer, 0.1-0.8wt% lubricant and 0.1-0.8wt% antioxidant, melt mix Refined, then extruded and granulated to obtain pellets;

[0027] (B) Injection molding the pellets to obtain a molded product;

[0028] (C) soaking the molded product in a solvent to obtain a polyoxymethylene product;

[0029] The soluble material is nanoscale ABS resin or nanoscale polyurethane, and the solvent is one or more of cyclohexane, benzene, acetone, butanone, toluene and tetrahydrofuran; or,

[0030] The soluble material is titanium dioxide, and the solvent is one or more of concentrated sulfuric acid and hydrofluoric acid.

[0031] According to the invention, polyoxymethylene products are prepared from polyoxymethylene, soluble materials, compatibilizers, lubricants ...

Embodiment 1

[0048] Add 76.7% by weight of polyoxymethylene, 20% of nano-level ABS and 2.6% of methyl acrylate-butadiene-styrene copolymer to a high-speed mixer and mix evenly, then add 0.5% of glycerol monostearate and four [ b-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester 0.2% mixed, after mixing evenly, the material was added to the hopper of the vented twin-screw extruder, After melting and kneading, extruding and granulating. The processing technology is as follows: extruder barrel temperature 150°C-200°C, screw speed 100r / min, and drying at 80°C for 3 hours to obtain pellets uniformly dispersed with nano ABS resin. Then the above granules are injection molded, the molding process is barrel 190°C, injection pressure 50MPa, injection time 50s, mold temperature 70°C, to obtain a molded product uniformly dispersed with nano-sized ABS resin. Finally, the above molded product is soaked in a container Put it in a special treatment tank with cyclohexane solvent, ta...

Embodiment 2

[0050] Add 66.8% by weight of polyoxymethylene, 28% of nano-sized ABS and 4.4% of ethylene-vinyl acetate copolymer to a high-speed mixer and mix evenly, then add 0.2% of pentaerythritol tristearate and bis[3-(3- tert-butyl-5-methyl-4-hydroxyphenyl) triethylene glycol propionate 0.6% is mixed, and after being mixed evenly, material is joined in the feed hopper of exhaust type twin-screw extruder, After melting and kneading, extruding and granulating. The processing technology is as follows: extruder barrel temperature 160°C, screw speed 180r / min, and drying at 85°C for 4 hours to obtain pellets uniformly dispersed with nano ABS resin. Then the above granules are injection molded, the molding process is cylinder 200°C, injection pressure 55MPa, injection time 40s, mold temperature 80°C, to obtain molded products uniformly dispersed with nano-sized ABS resin. Finally, soak the above molded product in a special treatment tank equipped with cyclohexane solvent, take it out after 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com