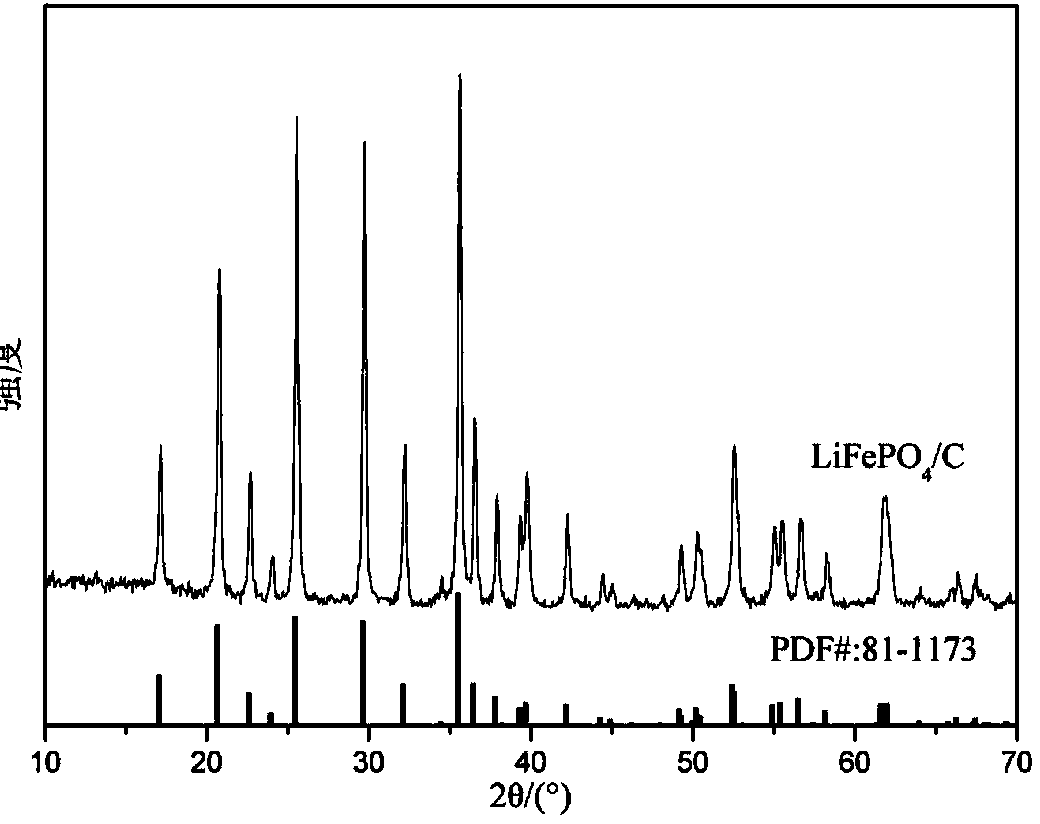

Preparation method of lithium ion phosphate/carbon composite material for high-rate-capability lithium ion battery

A technology of lithium-ion batteries and carbon composite materials, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of high-rate performance that have not been reported, and achieve good high-rate electrochemical performance, reduced energy consumption, and fine particles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the lithium iron phosphate / carbon composite material for the high-rate performance lithium-ion battery of the present embodiment is characterized in that: comprising the following steps:

[0030] a. Preparation of lithium iron phosphate precursor: mix ferrous phosphate powder into lithium source, phosphorus source and conductive additive according to the ratio of Li:Fe:P=1.02-1:0.98-1:1, then add liquid phase reducing agent and Heating to the boiling point of the reducing agent solvent and reflux at normal pressure, and finally separating the reducing agent from the liquid phase system (such as reducing the reducing agent by distillation under reduced pressure) to obtain a lithium iron phosphate precursor; the reaction process does not require high-temperature calcination and inert gas protection A lithium iron phosphate positive electrode material whose surface is covered with a layer of conductive agent is prepared.

[0031] Conductive additi...

Embodiment 1

[0044] 1) Adjust the pH value to 2 with sulfuric acid and react the ferrous sulfate solution with a molar concentration of 2 mol / L and 2 mol / L ammonium dihydrogen phosphate solution in a stoichiometric ratio of 3:2, adjust the pH value to 6.0 to obtain ferrous phosphate Precipitate, quickly filtered and washed to free of SO 4 2- , put the wet filter cake in the air at room temperature to air-dry, and measure the iron and phosphorus content for later use.

[0045] 2) Add lithium source, phosphorus source, and conductive additive to the ferrous phosphate powder obtained in 1) according to the stoichiometric ratio of lithium: iron: phosphorus = 1.00:0.98:1, and then add a liquid phase reducing agent; the mass of the conductive additive is 15% of the mass of the prepared lithium iron phosphate, the molar ratio of the liquid-phase reduction solvent to the prepared lithium iron phosphate is 10:1; transfer it to a three-necked bottle, heat it with a temperature-regulating electric h...

Embodiment 2

[0052] 1) React the ferrous sulfate solution with sulfuric acid to adjust the pH value to 2 and the molar concentration of 1.5 mol / L with 1.5 mol / L ammonium dihydrogen phosphate solution according to the stoichiometric ratio of 3:2, and adjust the pH value to 5.8 to obtain phosphoric acid Ferrous precipitation, quickly filtered and washed to no SO 4 2- , put the wet filter cake in the air at room temperature to air-dry, and measure the iron and phosphorus content for later use.

[0053] 2) Add lithium source, phosphorus source and conductive additive to the ferrous phosphate powder obtained in 1) according to the stoichiometric ratio of lithium: iron: phosphorus = 1.01:0.99:1, and then add a liquid phase reducing agent. The mass of the conductive additive is 5% of the obtained lithium iron phosphate mass; the molar ratio of the liquid-phase reduction solvent to the obtained lithium iron phosphate is 8:1; transferred to a three-necked bottle, heated with a temperature-regulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com