Corrosion resistance steel and production method thereof

A technology for corrosion-resistant steel and molten steel, which is applied in the field of alloy steel and can solve problems such as expensive alloying elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a preparation method for the above-mentioned corrosion-resistant steel, comprising the following steps:

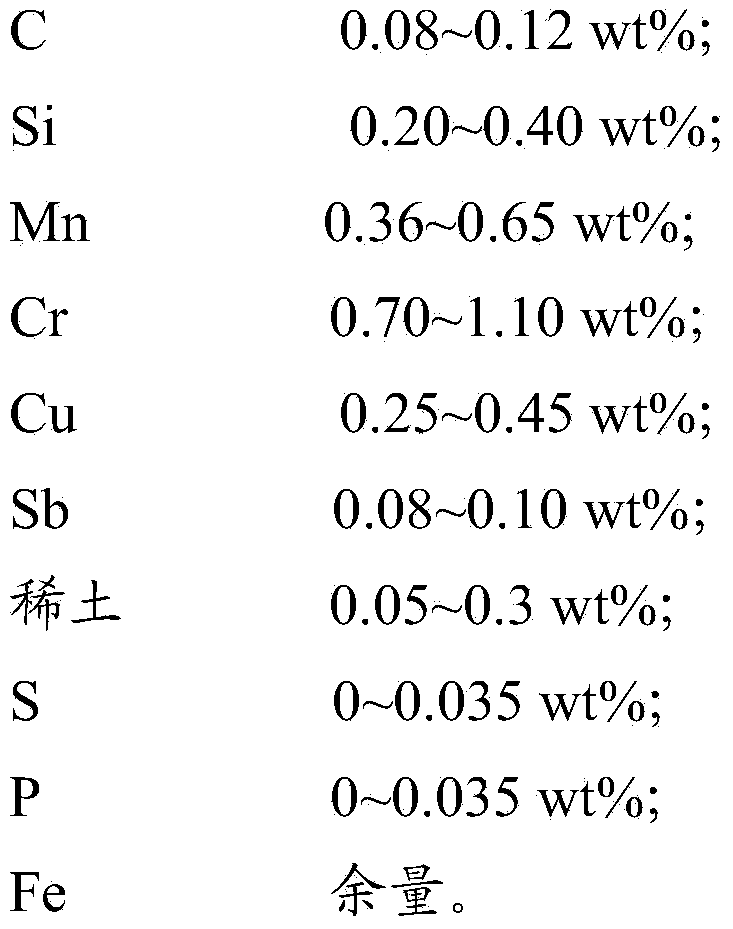

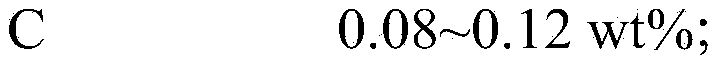

[0040]A) 0.08-0.12wt% of C, 0.20-0.40wt% of Si, 0.36-0.65wt% of Mn, 0.70-1.10 of Cr, 0.25-0.45wt% of Cu, 0-0.035wt% of S, 0 ~0.035wt% P and Fe are mixed and smelted to obtain molten steel;

[0041] B) Put 0.05-0.3wt% rare earth into the bottom of the ladle, pour the first volume part of molten steel, add 0.08-0.10wt% Sb, then pour the second volume part of molten steel, and stir to obtain the sample Sample;

[0042] C) heat-treating the sample to obtain corrosion-resistant steel;

[0043] The Fe is the balance.

[0044] The present invention has no special limitation on the sources of all raw materials, which can be commercially available, and it is preferable to select relevant metal materials or alloy materials according to the content of metal elements. Wherein, the contents of the metal elements are the same as those menti...

Embodiment 1

[0058] 1.1 According to the composition of raw material elements: 0.1wt% C, 0.3wt% Si, 0.45wt% Mn, 1.0wt% Cr, 0.4wt% Cu, 0.10wt% Sb, 0.05wt% Y, S≤ 0.035wt%, P≤0.035wt% and the balance of Fe. Weigh mineral raw materials 10# steel, low chromium cast iron, red copper, antimony and rare earth Y, with a total weight of 8kg; manually knock and crush the rare earth Y block to 2-3mm powder.

[0059] 1.2 Heat the 10# steel weighed in 1.1 to 1600°C in a 10kg medium-frequency induction furnace and melt it. After the molten steel is melted, add low-chromium cast iron and red copper in sequence, and heat it to 1650°C. After deoxidation and slag removal on the molten steel surface, the electric furnace was turned off and sedated for 2 minutes, and then the electric furnace was turned on again to raise the temperature to 1650°C, and the aluminum wire deoxidation treatment and slag removal treatment were performed again to obtain molten steel.

[0060] 1.3 Put 4g of the rare earth Y powder o...

Embodiment 2

[0065] 2.1 According to the composition of raw material elements: 0.1wt% C, 0.3wt% Si, 0.45wt% Mn, 1.0wt% Cr, 0.4wt% Cu, 0.10wt% Sb, 0.15wt% Y, S≤ 0.035wt%, P≤0.035wt% and the balance of Fe. Weigh mineral raw materials 10# steel, low chromium cast iron, red copper, antimony and rare earth Y, with a total weight of 8kg; manually knock and crush the rare earth Y block to 2-3mm powder.

[0066] 2.2 Heat the 10# steel weighed in 2.1 to 1600°C in a 10kg medium-frequency induction furnace to melt. After the molten steel is melted, add low-chromium cast iron and red copper in sequence, and heat it to 1650°C. After deoxidation and slag removal on the molten steel surface, the electric furnace was turned off and sedated for 2 minutes, and then the electric furnace was turned on again to raise the temperature to 1650°C, and the aluminum wire deoxidation treatment and slag removal treatment were performed again to obtain molten steel.

[0067] 2.3 Put 12g of the rare earth Y powder obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Self-corrosion current density | aaaaa | aaaaa |

| Self-corrosion current density | aaaaa | aaaaa |

| Self-corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com