Preparation method of low-cost high-corrosion-resistance Monel metal coating

An alloy coating and corrosion-resistant technology, applied in the field of preparing Monel alloy coating, can solve the problem of high cost and achieve the effects of low cost, reduced self-corrosion current density and excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

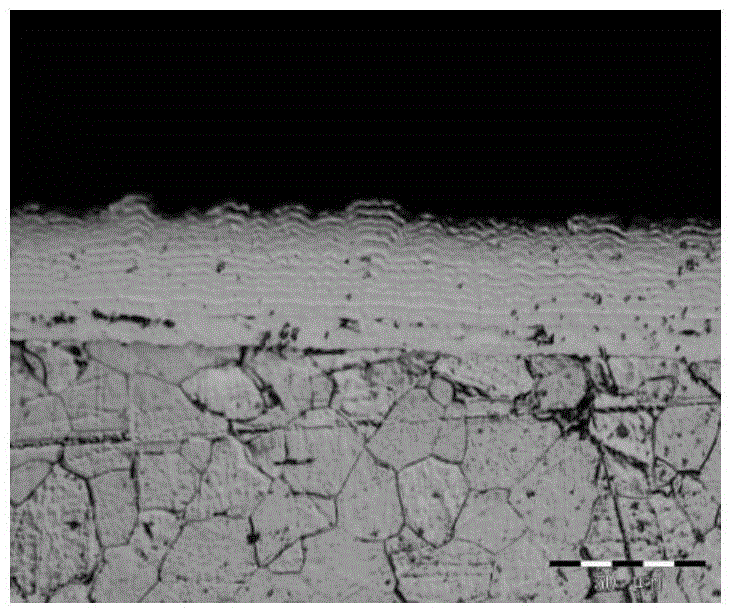

[0016] Embodiment 1: In this embodiment, the preparation method of Monel alloy coating on the surface of steel with low cost and high corrosion resistance is realized according to the following steps: 1. The steel surface is subjected to mechanical pretreatment. Roughly grind the steel surface with 800# sandpaper, then scrub with acetone to remove oil and rust. 2. Pre-treat the steel surface before plating. (1) The test piece is connected to a positive voltage of 10-20V, and the surface is brushed with an electric cleaning solution (alkaline) for 10-30s, and then rinsed with water; (2) The test piece is connected to a reverse voltage. Connect to 10-20V, brush the surface with No. 2 activation solution (acid) for 10-30s, and then rinse with water; (3) The test piece is connected to the voltage reversely connected to 10-20V, and the surface is brushed with No. 3 activation solution (acid) for 10-30s, Rinse with water. 3. Conduct electric brush plating on the surface of the work...

specific Embodiment approach 2

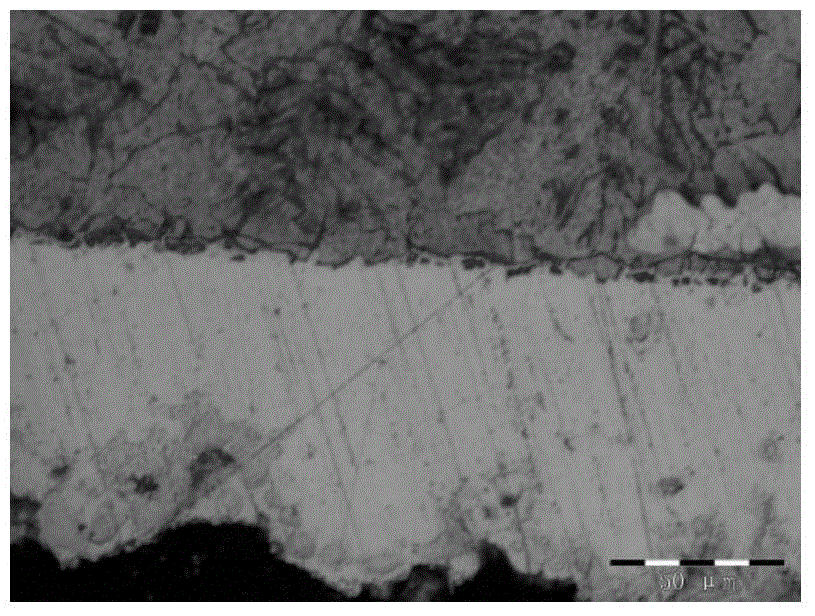

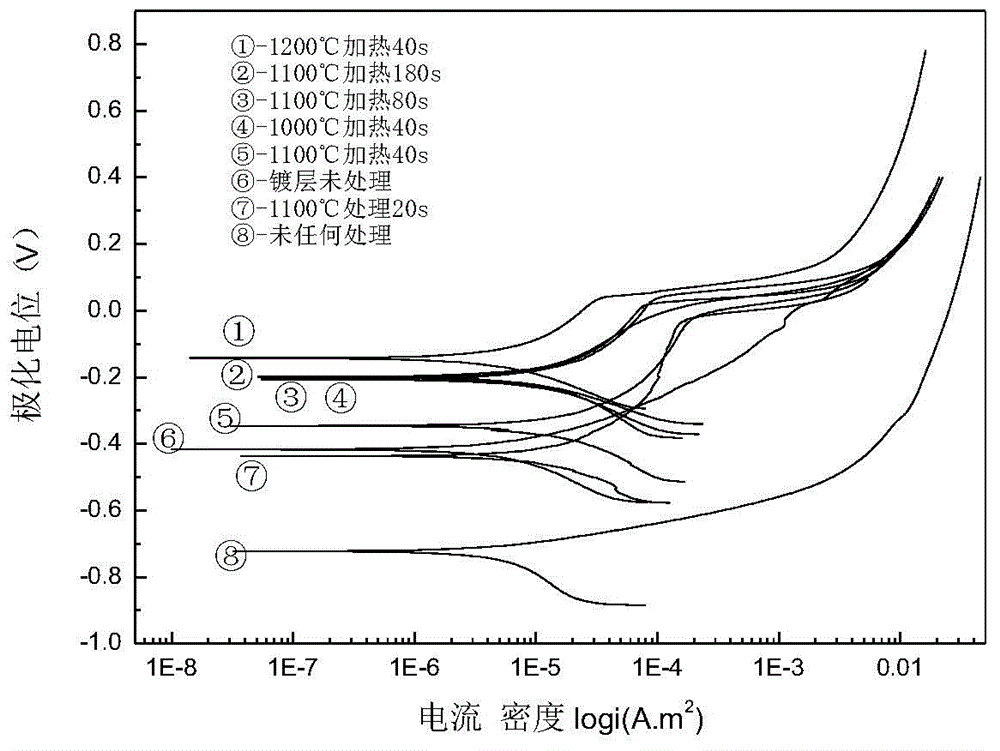

[0034] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 4, a high-temperature heat treatment furnace is used for long-term heat treatment, the heating temperature is 200°C-1200°C, and the holding time is 2min-20h. At this time, the self-corrosion potential is about -0.2, and the self-corrosion current density is significantly lower than that in the first method.

[0035] Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com