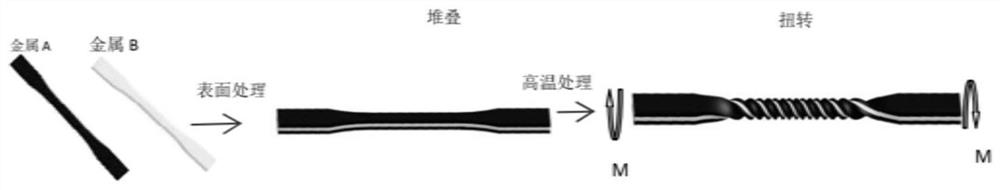

A method for preparing multi-layer metal composite materials by high temperature torsion

A composite material and multi-layer metal technology, which is applied in the high-temperature torsion preparation of multi-layer metal composite materials and new multi-layer metal material composite technology, can solve the problems of deformation instability, uneven deformation of metal composite materials, and short deformation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

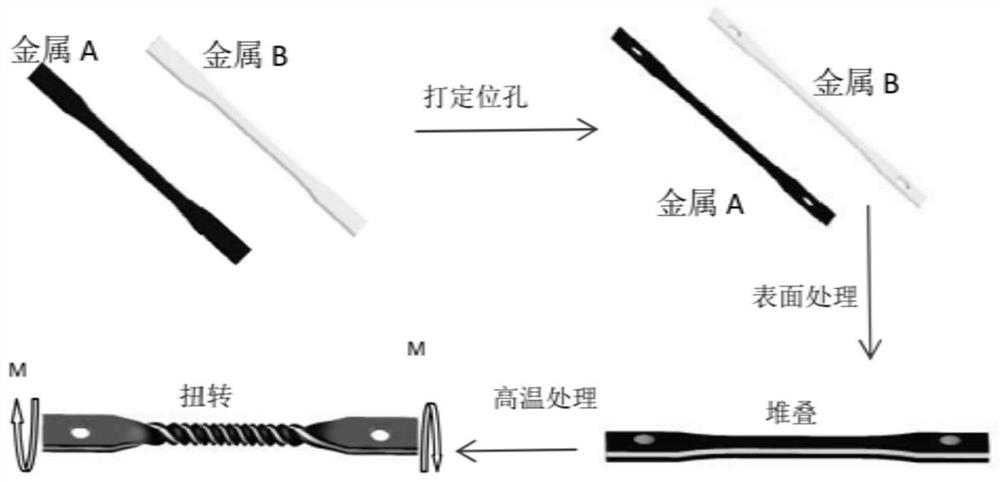

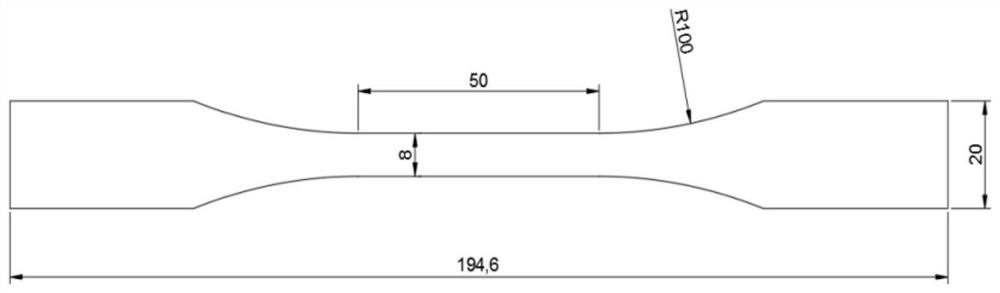

[0064] 1. Cut the 1060 aluminum alloy plate and the 304 stainless steel plate with a thickness of 3mm into torsion samples in the shape of Figure 2(a) by wire cutting;

[0065] 2. Place the cut sample on the grinder to remove the oxide layer on the surface, exposing the smooth metal layer, and then clean the polished plate with alcohol and dry it;

[0066] 3. Alternately stack two 1060 aluminum alloy plates and one 304 stainless steel plate of 3mm after surface treatment, and place the 304 stainless steel plate on the center layer;

[0067] 4. Fix the stacked sample into the fixture, and then install the fixture with the sample on the torsion testing machine (such as Figure 4b ), and then install the heating furnace (such as Figure 4c ), heat the sample, and when the temperature of the heating furnace reaches the specified temperature of 500°C, carry out the heat preservation treatment for 5 minutes;

[0068] 5. The stacked samples after heat preservation treatment were tw...

example 2

[0081] 1. Cut the 1060 aluminum alloy plate and the 304 stainless steel plate with a thickness of 3 mm into the sample in the shape of Figure 2 (a) by wire cutting;

[0082] 2. Place the cut sample on the grinder to remove the oxide layer on the surface, exposing the smooth metal layer, and then clean the polished plate with alcohol and dry it;

[0083] 3. Alternately stack two 1060 aluminum alloy plates and one 304 stainless steel plate of 3mm after surface treatment, and place the 304 stainless steel plate on the center layer;

[0084] 4. Fix the stacked sample into the fixture, then install the fixture with the sample on the torsion testing machine (as shown in Figure 4(b)), and then install the heating furnace (as shown in Figure 4(c)), and test the sample Carry out heat treatment, when the temperature of the heating furnace reaches the specified temperature of 200°C, 300°C, and 500°C respectively, carry out heat preservation treatment for 5 minutes;

[0085] 5. Conduct t...

Embodiment 3

[0091] 1. Process the 1060 aluminum alloy plate and 304 stainless steel plate with a thickness of 1.5mm into a sample in the shape of Figure 2(a);

[0092] 2. Place the cut sample on a belt grinder to remove the oxide layer on the surface, exposing the smooth metal layer, and then clean the polished plate with alcohol;

[0093] 3. Stack the surface-treated 1060 aluminum alloy plates and 304 stainless steel plates alternately;

[0094] 4. Fix the stacked sample into the fixture, and then install the fixture with the sample on the torsion testing machine (such as Figure 4b ), and then install the heating furnace (such as Figure 4c ), heat treatment is performed on the sample, and when the temperature of the heating furnace reaches the specified temperature of 500°C, heat preservation treatment is carried out for 5 minutes;

[0095] 5. The stacked samples after heat preservation treatment were twisted 1080° and 1440° respectively at a speed of 60r / min to obtain a 1060 aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com