A nicralsi/ceo 2 Doped YSZ thermal barrier coating and preparation method thereof

A technology of thermal barrier coating and deposition layer, which is applied in the direction of coating, metal material coating process, vacuum evaporation plating, etc., can solve the expansion and peeling of bonding layer and ceramic layer, increase the growth rate of TGO layer, ceramic layer Problems such as the gap with the bonding layer, to prevent the peeling of the coating, to achieve the interdiffusion of elements, and to achieve the effect of a firm coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

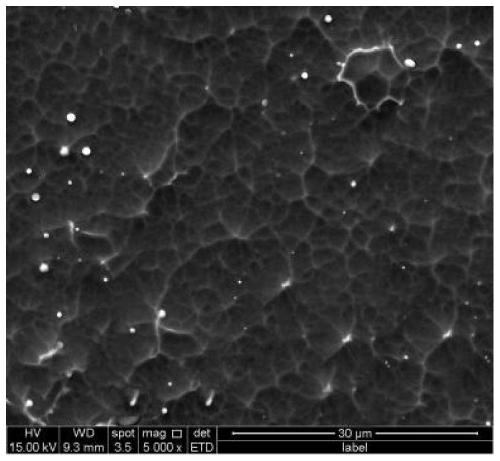

Image

Examples

Embodiment 1

[0029] In this embodiment, the mass percentage of each element in NiCrAlSi is: Cr 50wt%, Ni 20wt%, Al 5wt%, Si 25wt%. YSZ is Y 2 o 3 Stable ZrO 2 , where Y2 o 3 The mass percentage is 6%.

[0030] NiCrAlSi / CeO 2 Preparation method of doped YSZ thermal barrier coating:

[0031] (1) Before installing the NiCrAlSi target, polish it with 320-grit sandpaper to remove the oxide layer, ultrasonically clean it in absolute ethanol, and then dry it;

[0032] (2) The material of the matrix 4 is cast 7-TiAl-based intermetallic compound alloy. Using the wire electric discharge cutting technology, the matrix 4 is made into a sample with a size of 15mm×15mm×4mm, and then polished with 320-grit sandpaper. Polished with 2.5μm diamond abrasive paste, ultrasonically cleaned with acetone solution, and dried for later use;

[0033] (3) A plasma etching system is adopted, hydrogen and argon etching gases are selected, and the etching process parameters are as follows: power 2000W, hydrogen f...

Embodiment 2

[0047] In this embodiment, the mass percent of each element in NiCrAlSi is: Cr 70wt%, Ni 10wt%, Al 15wt%, Si 5wt%. YSZ is Y 2 o 3 Stable ZrO 2 , where Y 2 o 3 The mass percentage is 8%.

[0048] NiCrAlSi / CeO 2 Preparation method of doped YSZ thermal barrier coating:

[0049] (1) Before installing the NiCrAlSi target, polish it with 320-grit sandpaper to remove the oxide layer, ultrasonically clean it in absolute ethanol, and then dry it;

[0050] (2) The material of the matrix 4 is a cast γ-TiAl-based intermetallic compound alloy. The matrix 4 is made into a sample with a size of 15mm×15mm×4mm by using the wire electric discharge cutting technology, and then polished with 400-grit sandpaper. Polished with 2.5μm diamond abrasive paste, ultrasonically cleaned with acetone solution, and dried for later use;

[0051] (3) A plasma etching system is adopted, hydrogen and argon etching gases are selected, and the etching process parameters are as follows: power 2500W, hydroge...

Embodiment 3

[0064] In this embodiment, the mass percent of each element in NiCrAlSi is: Cr 60wt%, Ni 15wt%, Al 10wt%, Si 15wt%. YSZ is Y 2 o 3 Stable ZrO 2 , where Y 2 o 3 The mass percentage is 7%.

[0065] NiCrAlSi / CeO 2 Preparation method of doped YSZ thermal barrier coating:

[0066] (1) Before installing the NiCrAlSi target, polish it with 320-grit sandpaper to remove the oxide layer, ultrasonically clean it in absolute ethanol, and then dry it;

[0067] (2) The material of the matrix 4 is a cast γ-TiAl-based intermetallic compound alloy. The matrix 4 is made into a sample with a size of 15mm×15mm×4mm by using the wire electric discharge cutting technology, and then polished with 600-grit sandpaper. Polished with 2.5μm diamond abrasive paste, ultrasonically cleaned with acetone solution, and dried for later use;

[0068] (3) A plasma etching system is adopted, hydrogen and argon etching gases are selected, and the etching process parameters are as follows: power 2250W, hydrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com