A preparation method of high dielectric polyimide/copper calcium titanate nanowire composite material

A technology of calcium copper titanate and polyimide is applied in the field of preparation of high-dielectric polyimide/calcium copper titanate (CCTO) nanowire composite materials, which can solve the difficulty of macromolecular intercalation and reduce percolation. The problem of high threshold and aspect ratio can reduce the percolation threshold, save manpower, and improve the dielectric properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

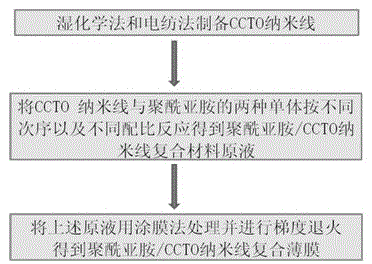

[0040] a) press figure 1 According to the procedure in , weigh 2.554 g of diaminodiphenyl ether (ODA) into a three-necked bottle containing 7.4 ml of N,N-dimethylacetamide (DMAC) solution.

[0041] b) Weigh 0.048 g of CCTO nanowire powder (mass fraction: 1%) and add it into the above mixture, and perform magnetic stirring while adding.

[0042] c) Put the solution obtained in b) into an ultrasonic disperser for 2 hours to mix the solution evenly.

[0043] d) Weigh 2.835 grams of pyromellitic dianhydride (PMDA) and add it to the mixed solution, stir magnetically while adding, and then react at room temperature for 4 hours in a nitrogen-protected environment to obtain polyimide / Stock solution of CCTO nanowire composites.

[0044] e) Pour the original solution of the composite material on the glass substrate, spread it flat, put it in a muffle furnace, anneal it in a vacuum environment, and keep it at 60°C, 100°C, 200°C and 300°C for 1 hour , and then cool down naturally, wi...

Embodiment 2

[0050] a) press figure 1 According to the procedure in , weigh 2.554 g of diaminodiphenyl ether (ODA) into a three-necked bottle containing 74 ml of N,N-dimethylacetamide (DMAC) solution.

[0051] b) Weigh 0.154 g of the prepared CCTO nanowire powder (mass fraction is 3%) and add it into the above mixture, and perform magnetic stirring while adding.

[0052] c) Put the solution obtained in b) into an ultrasonic disperser for 2 hours to mix the solution evenly.

[0053] d) Weigh 2.835 grams of pyromellitic dianhydride (PMDA) and add it to the mixture, stir it magnetically while adding, and then react at room temperature for 12 hours in a nitrogen-protected environment to obtain polyimide / Stock solution of CCTO nanowire composites.

[0054] e) Pour the original solution of the composite material on the glass substrate, spread it flat, put it in a muffle furnace, anneal it in a vacuum environment, and keep it at 60°C, 100°C, 200°C and 300°C for 1 hour , and then cool down na...

Embodiment 3

[0060] a) press figure 1 According to the procedure in , weigh 2.554 g of diaminodiphenyl ether (ODA) into a three-necked bottle containing 74 ml of N,N-dimethylacetamide (DMAC) solution.

[0061] b) Weigh 0.499 g of the prepared CCTO nanowire powder (mass fraction is 8%) and add it into the above mixture, and perform magnetic stirring while adding.

[0062] c) Put the solution obtained in b) into an ultrasonic disperser for 2 hours to mix the solution evenly.

[0063] d) Weigh 2.835 grams of pyromellitic acid dianhydride (PMDA) and add it to the mixed solution, stir magnetically while adding, and then react at room temperature for 8 hours in a nitrogen-protected environment to obtain polyimide / Stock solution of CCTO nanowire composites.

[0064] e) Pour the original solution of the composite material on the glass substrate, spread it flat, put it in a muffle furnace, anneal it in a vacuum environment, and keep it at 60°C, 100°C, 200°C and 300°C for 1 hour , and then cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com