A method for preparing ultrafine ultrahigh aspect ratio silver nanowires

A technology of silver nanowires and aspect ratio, applied in nanotechnology, metal processing equipment, transportation and packaging, etc., can solve the problems of high toxicity of reducing agents, low yield of silver nanowires, affecting the application of silver nanowires, etc., to achieve The effect of easy control of reaction conditions and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

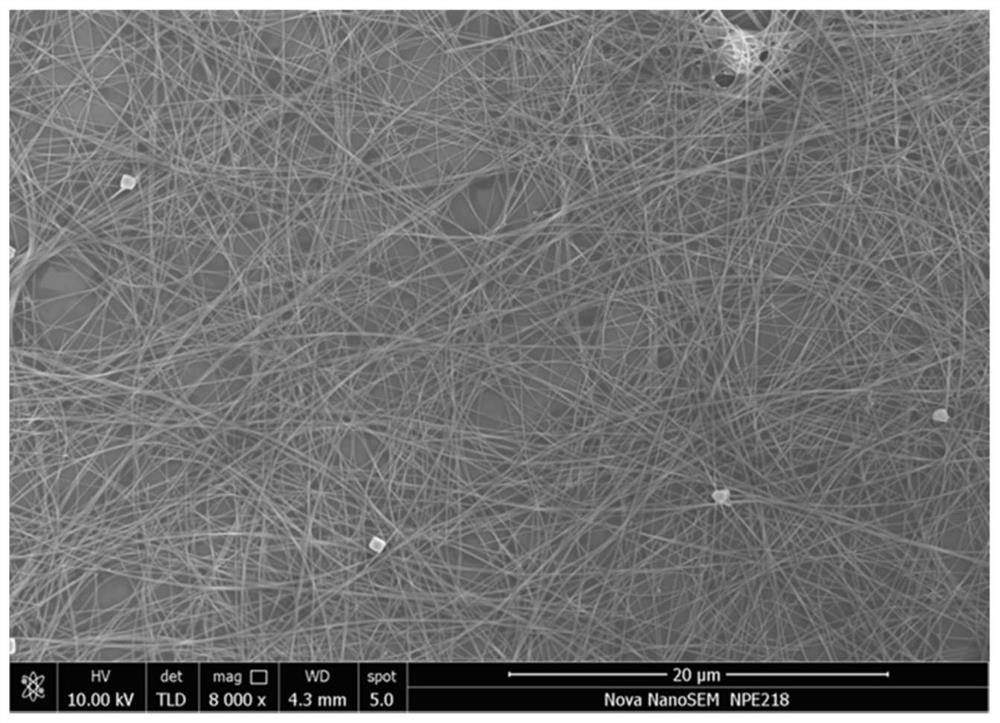

[0034] 2g glucose, 1ml 0.2mol / L NH 4 Br, 2mL 0.2mol / L NH 4Cl was added to a solution containing 40 mL of polyvinylpyrrolidone with a concentration of 0.025 g / mL (solvent being ethylene glycol) to obtain solution A; 0.4 g of silver nitrate was added to 20 ml of ethylene glycol solution to prepare 0.02 g / mL of solution B; Heat solution A to 160°C under nitrogen protection, then add solution B to solution A at a rate of 0.25 mL / min; adjust the stirring speed to 80 r / min. After reacting for 1 hour, stop the reaction, and cool it to room temperature, then add 200ml of ethanol for centrifugal washing, and the obtained silver nanowires have a length of about 56 microns, a diameter of about 16 nanometers, and an aspect ratio of about 3500. like figure 1 shown. The square resistance (R 0 ) is 268Ω / □, the light transmittance is 99.1%, and the rear resistance is 446Ω / □ after repeated bending 1000 times, R / R 0 <2, showing good flexibility.

Embodiment 2

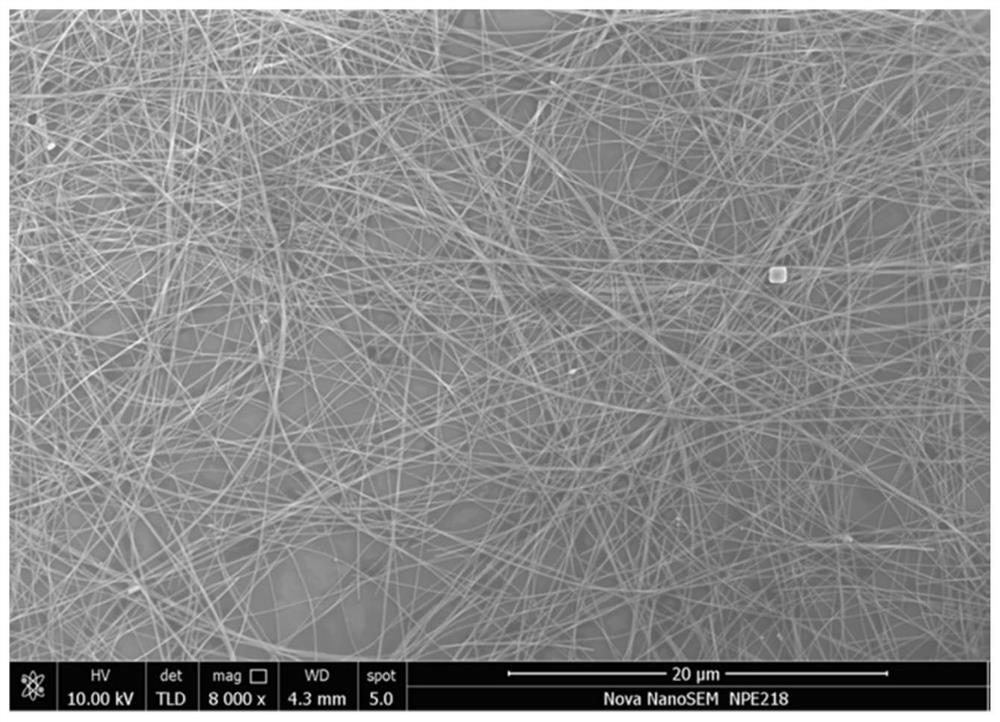

[0036] 2g glucose, 1ml 0.2mol / L NH 4 Br, 2mL 0.2mol / L NH 4 Cl was added to a solution containing 40 mL of polyvinylpyrrolidone with a concentration of 0.025 g / mL (solvent being ethylene glycol) to obtain solution A; 0.4 g of silver nitrate was added to 20 ml of ethylene glycol solution to prepare 0.02 g / mL of solution B; Heat solution A to 180°C under nitrogen protection, then add solution B to solution A at a rate of 0.25 mL / min; adjust the stirring speed to 80 r / min. After reacting for 1 hour, stop the reaction, and cool it to room temperature, then add 200ml of ethanol and wash it by centrifugation. The obtained silver nanowires have a length of about 68 microns, a diameter of about 20 nanometers, and an aspect ratio of about 3400. Its appearance is as follows: figure 2 shown. The square resistance (R 0 ) is 198Ω / □, the light transmittance is 97.6%, and the rear resistance is 235Ω / □ after repeated bending 1000 times, R 0 / R<2, with better flexibility.

Embodiment 3

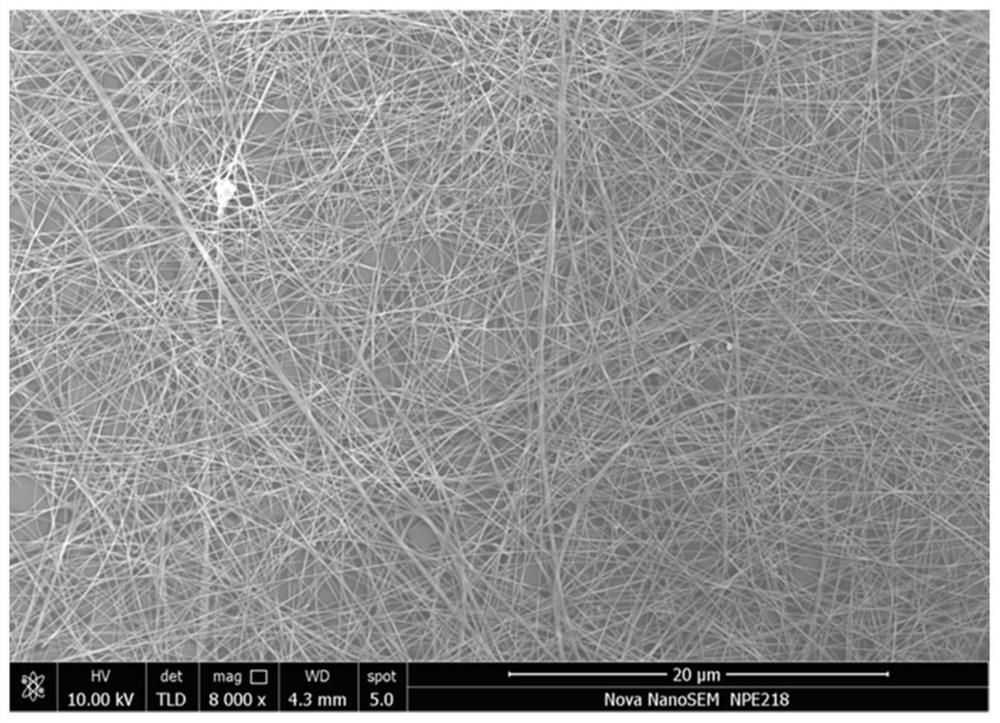

[0038] 3g glucose, 1ml 0.2mol / L NH 4 Br, 2mL 0.2mol / L NH 4 Cl was added to a solution containing 40 mL of polyvinylpyrrolidone with a concentration of 0.025 g / mL (solvent being ethylene glycol) to obtain solution A; 0.4 g of silver nitrate was added to 20 ml of ethylene glycol solution to prepare 0.02 g / mL of solution B; Heat solution A to 160°C under nitrogen protection, then add solution B to solution A at a rate of 0.25 mL / min; adjust the stirring speed to 80 r / min. After reacting for 2 hours, stop the reaction, and cool it to room temperature, then add 200ml of ethanol for centrifugal washing, the obtained silver nanowires have a length of about 80 microns, a diameter of about 23 nanometers, and an aspect ratio of 3480. Its appearance is as follows: image 3 shown. The square resistance (R 0 ) is 180Ω / □, the light transmittance is 96.9%, and the rear resistance (R) after bending 1000 times is 241Ω / □, R / R 0 <2, showing good flexibility.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com