Photo-thermal double-curing conductive adhesive and preparation method thereof

A dual-curing, conductive adhesive technology, applied in the direction of conductive adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of batch production restrictions, long curing time, incomplete curing, etc., and achieve improved Efficiency, short curing time, and the effect of improving the degree of curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

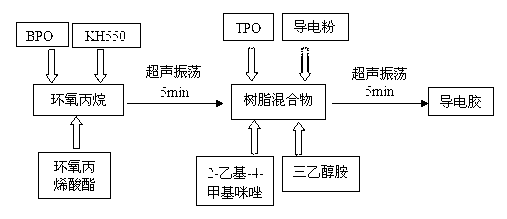

Image

Examples

Embodiment 1

[0030] Use 5 / 8 esterification rate epoxy acrylate to add diluent (propylene oxide) 20%, thermal initiator (BPO) 1.5%, silane coupling agent (KH550) 4%, photoinitiator (TPO) 3.0%, Thermal curing agent (triethanolamine) 10%, accelerator (2-ethyl-4-methylimidazole) 5%, conductive filler (Cu powder) 60%, according to figure 1 In the process shown, the conductive adhesive is prepared and cured, the curing time is 300s, the temperature is 120°C, the hardness after curing is 6H, and the resistivity is 4.6×10 -3 Ω·m, the tensile strength is 23.25MPa.

Embodiment 2

[0032] The difference between this example and Example 1 is that the diluent is propylene oxide, and its addition amount is 30%, and then a conductive adhesive is configured, and a photothermal dual curing method is adopted, and the ultraviolet light is irradiated for 300s, and the hardness after curing is 5H. , resistivity 3.6×10 -3 Ω·m, the tensile strength is 23.56MPa.

Embodiment 3

[0034] The difference between this embodiment and the second embodiment is that the ultraviolet light is irradiated for 600s, the conductive adhesive is configured, and the photothermal dual curing method is adopted. After curing, the hardness is 6H, and the resistivity is 3.5×10 -3 Ω·m, the tensile strength is 23.75MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com