Polyamide acid aqueous sizing agent as well as preparation method and application thereof

A polyamic acid water-based, polyamic acid technology, used in textiles and papermaking, fiber processing, carbon fiber, etc., to achieve the effect of promoting contact, good particle size distribution uniformity, and good film-forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

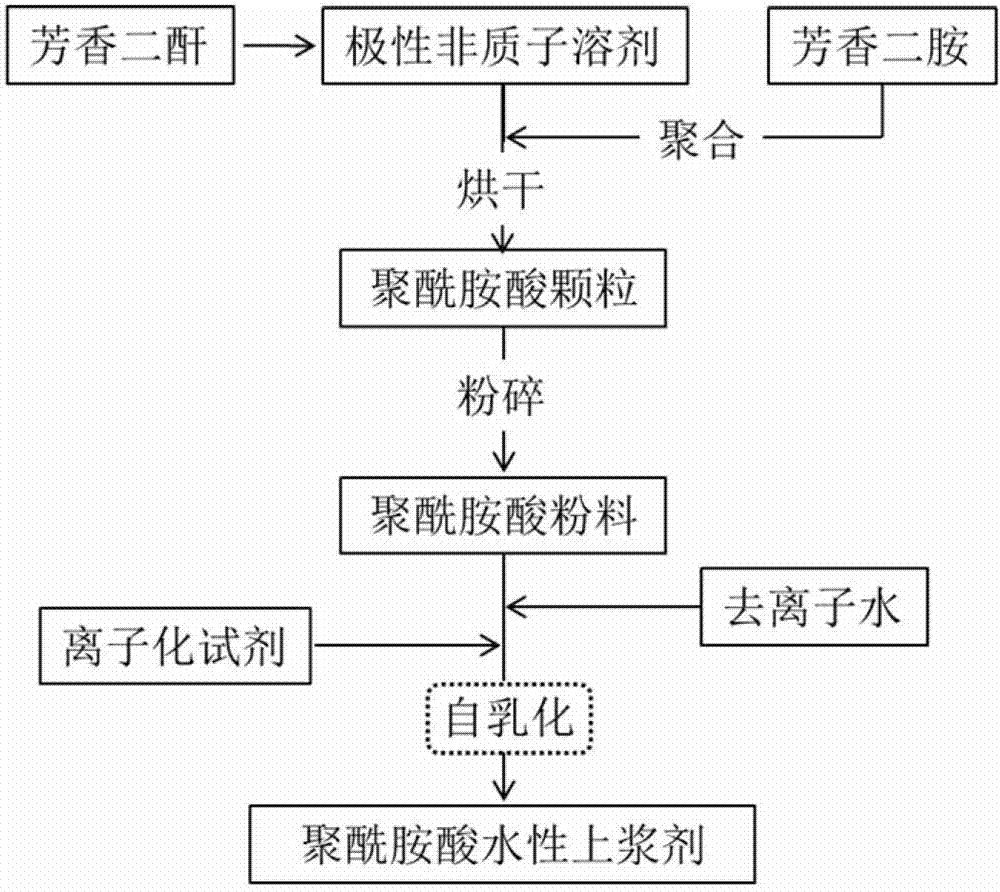

Method used

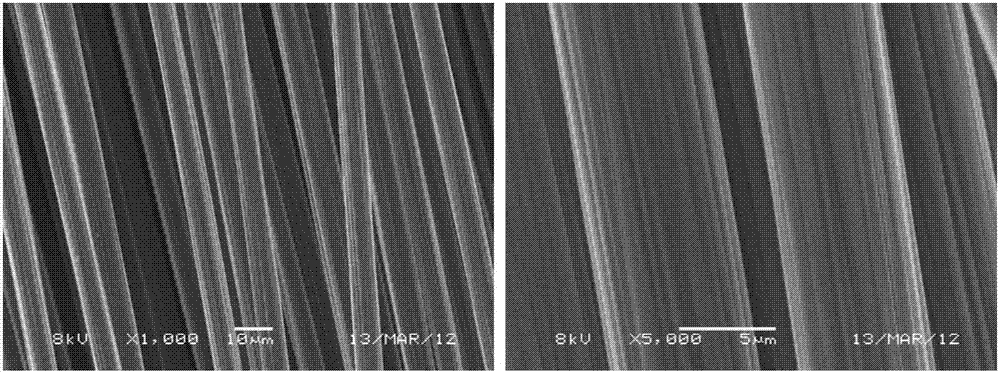

Image

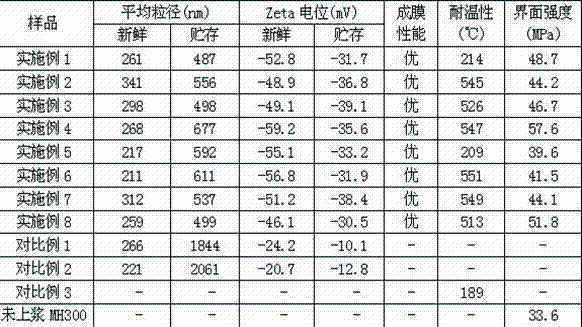

Examples

Embodiment 1

[0033] Under nitrogen protection, weigh 322.22g of 3,3',4,4'-benzophenonetetracarboxylic dianhydride, and add it to 1.66L of N,N'-dimethylformamide under stirring conditions, After all the solution was dissolved, 200.24 g of 4,4'-diaminodiphenyl ether was added, and the polycondensation reaction was continued for 2 hours at 0° C. under stirring to obtain a homogeneous and transparent polyamic acid solution. Next, vacuum-dry the polyamic acid solution at 40° C., and pulverize it to obtain polyamic acid powder. Then 50 g of polyamic acid powder was weighed and added to 1 L of deionized water, and 5 g of triethylamine was slowly added to the system under stirring. Continue to maintain the temperature and stir for 1 h after stopping the addition of the ionizing agent to obtain a polyamic acid water-based sizing agent.

[0034]Before sizing, add deionized water into the sizing agent under the condition of stirring, so that the final concentration is 0.5wt%. The prepared sizing...

Embodiment 2

[0036] Under the protection of argon, weigh 218.12g of pyromellitic dianhydride, add it into 1.77L of N,N'-dimethylacetamide under stirring conditions, and add 200.24g of 3, For 4'-diaminodiphenyl ether, the polycondensation reaction was continued for 24 hours at 25° C. under stirring conditions to obtain a homogeneous and transparent polyamic acid solution. Next, vacuum-dry the polyamic acid solution at 80° C., and pulverize it to obtain polyamic acid powder. Then weigh 50 g of polyamic acid powder and add it into 1 L of deionized water, and slowly add 20 g of tributylamine into the system under stirring until the polyamic acid is completely emulsified. After stopping the addition of the ionizing agent, continue to maintain the temperature and stir for 3 hours to obtain a polyamic acid water-based sizing agent.

[0037] Before sizing, add deionized water into the sizing agent under the condition of stirring, so that the final concentration is 1%. Pour the prepared siz...

Embodiment 3

[0039] Under the protection of nitrogen, take by weighing 520.49g of bisphenol A type dianhydride, join in the N-methylpyrrolidone of 1.84L under the condition of stirring, treat to add the m-phenylenediamine of 108.14g after all dissolving, polycondensation reaction is in Continue for 12 hours at 15° C. under stirring conditions to obtain a homogeneous and transparent polyamic acid solution. Next, vacuum-dry the polyamic acid solution at 60° C., and pulverize it to obtain polyamic acid powder. Then weigh 200 g of polyamic acid powder and add it to 1 L of deionized water, and slowly add 10 g of tripropylamine into the system under stirring until the polyamic acid is completely emulsified. After stopping the addition of the ionizing agent, continue to maintain the temperature and stir for 2 hours to obtain a polyamic acid water-based sizing agent.

[0040] Before sizing, add deionized water into the sizing agent under the condition of stirring, so that the final concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com