Waterborne polyethersulfone sizing agent for carbon fiber and preparation method of waterborne polyethersulfone sizing agent

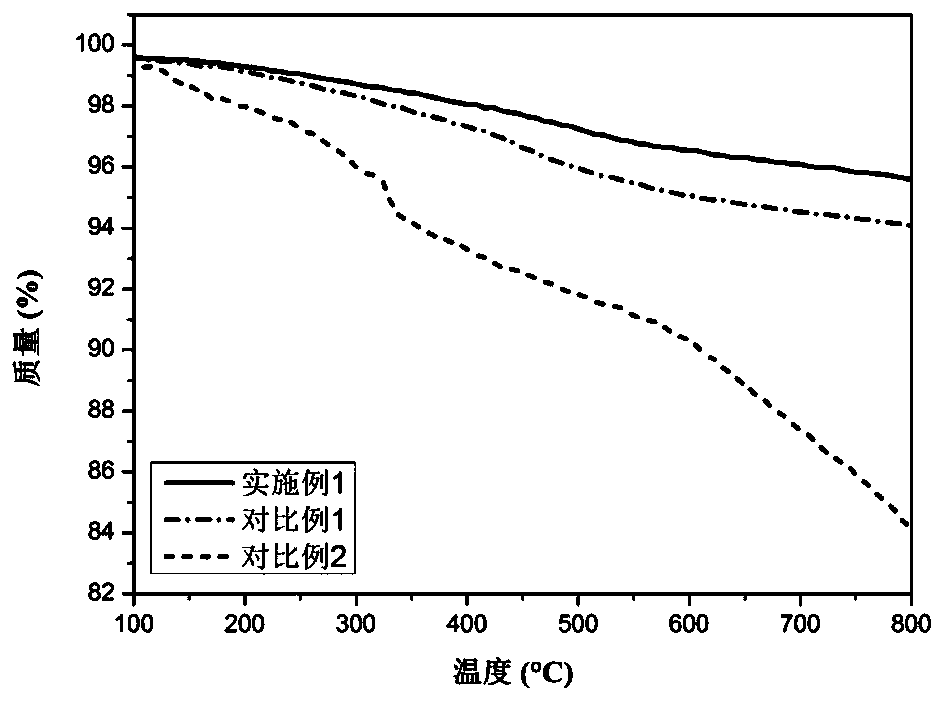

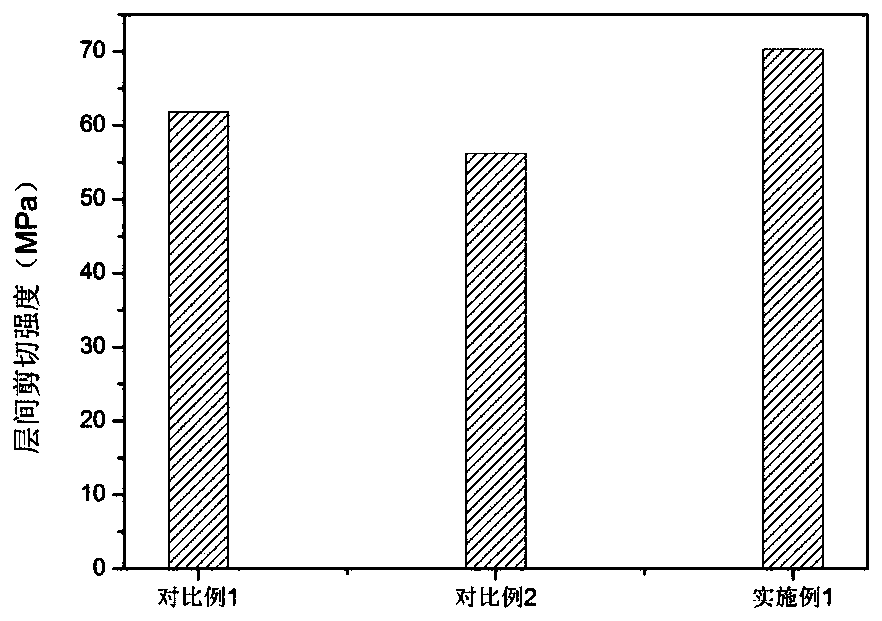

A water-based, polyethersulfone technology, applied in the direction of carbon fiber, fiber type, fiber treatment, etc., can solve the problems of poor heat resistance and compatibility, and achieve a simple and reliable preparation process, easy to repeat, and good industrialization prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides a method for preparing a water-based polyethersulfone sizing agent for carbon fibers, comprising:

[0039] Step 1: Dissolving the polyethersulfone resin in an organic solvent, fully stirring it to completely dissolve it to form a uniform resin solution; the organic solvent is preferably one of dichloromethane or chloroform;

[0040] Step 2: Add the surfactant into the deionized water, stir at 40-60°C for 30-60 minutes with a high-speed shear emulsification mixer, the speed is preferably 8000-12000 rpm, cool to room temperature, and obtain a solution;

[0041] Step 3: Slowly add the homogeneous resin solution obtained in Step 1 to the solution in Step 2 under high-speed stirring to obtain a mixed solution;

[0042] Step 4: Add the modified nano-carbon material to the mixed solution in Step 3, and add leveling agent, lubricant, adhesive and antistatic agent at the same time, and stir at a high speed for 30-60 minutes at a constant shear...

Embodiment 1

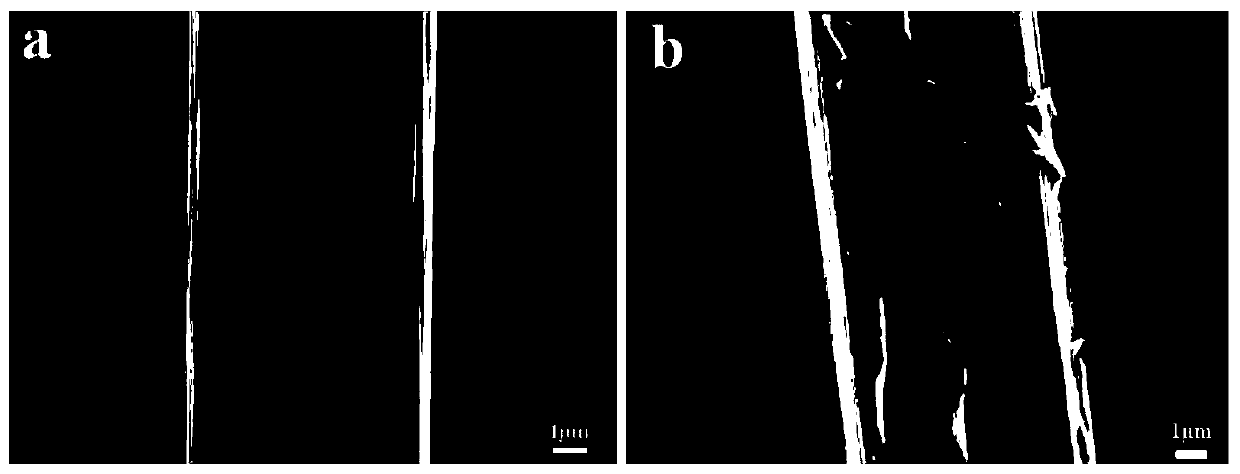

[0048] (1) Preparation of modified GO: First, add 0.1 g of GO and 2 g of 3,3'-diaminodiphenylsulfone to 100 mL of DMF, then add 5 g of dehydrating agent dicyclohexylcarbodiimide and 0.8 g of The catalyst 4-dimethylaminopyridine was stirred continuously at 40°C for 24 hours to react the amino functional group in the amino compound with the carboxyl functional group in GO. Then the reacted mixture was centrifuged three times, and washed with DMF to remove unreacted dicyclohexylcarbodiimide and 4-dimethylaminopyridine. Finally, the 3,3'-diaminodiphenylsulfone chemically grafted GO was obtained by vacuum drying at 80 °C.

[0049] (2) Dissolve 1 g of polyethersulfone resin in dichloromethane, stir well to completely dissolve it, and form a uniform solution.

[0050] (3) Add 0.5 g of sodium lauryl sulfate into 97.6 mL of deionized water, stir at 40° C. for 30 min with a high-speed shear emulsifying mixer, and cool to room temperature.

[0051] (4) The homogeneous resin solution ob...

Embodiment 2

[0060] (1) The nano-carbon material used in this example is carboxylated CNT, and the modifier, modification method and consumption are the same as in Example 1.

[0061] (2) Dissolve 2 g of polyethersulfone resin in dichloromethane, stir well to completely dissolve it, and form a uniform solution.

[0062] (3) Add 0.2 g of Tween-80 and 0.5 g of sodium lauryl sulfate into 96.3 mL of deionized water, stir at 50° C. for 30 min with a high-speed shear emulsifying mixer, and cool to room temperature.

[0063] (4) under water bath conditions, the uniform resin solution obtained in step (2) is slowly added dropwise to the solution in step (3) under high-speed stirring to obtain a mixed solution;

[0064] (5) In the mixed solution of step (4), add the CNT of 0.1g modification, add simultaneously 0.1g acrylic resin, 0.3g butyl stearate, 0.3g carboxymethyl cellulose and 0.2g polyether ester amide, Stir at high speed for 30 min at a constant shear rate.

[0065] (6) Stir the solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com