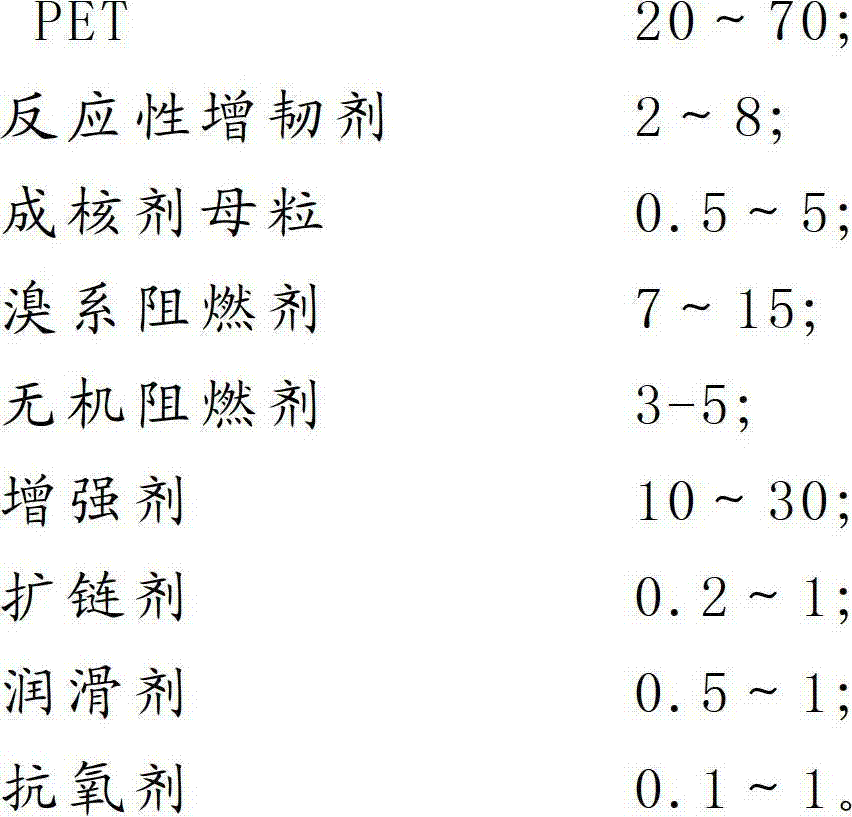

High heat-resistant fire-retardant reinforced polyethylene terephthalate (PET) composition and preparation method thereof

A composition, high heat resistance technology, applied in the field of engineering plastic modification, can solve problems such as effective utilization rate and poor heat resistance, and achieve the effects of excellent comprehensive performance, high thermal deformation temperature and short molding cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

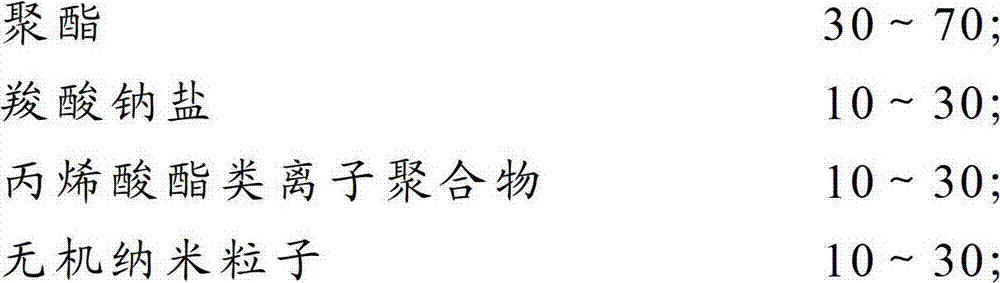

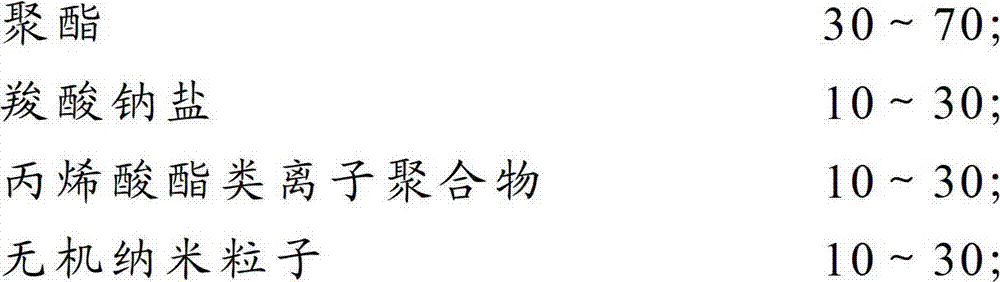

[0038] Preparation of nucleating agent masterbatch: take 50 parts of polyethylene terephthalate as carrier, add 10 parts of sodium benzoate, 30 parts of ethylene-acrylic acid copolymer sodium salt, and 10 parts of nano-calcium carbonate, and co-extrude through twin-screw Prepare the nucleating agent masterbatch by granulation, and dry the pellets at 120°C for 6 hours for later use;

[0039] Extrusion molding: 50 parts of polyethylene terephthalate ([η]=0.67, Tm=250°C), 1 part of the above-mentioned nucleating agent masterbatch, ethylene-methyl acrylate-glycidyl methacrylate 5 parts of copolymer, 10 parts of decabromodiphenylethane, 4 parts of antimony trioxide, 0.5 parts of lubricant ethylene bisstearamide, 0.2 parts of chain extender acrylic polymer, 0.5 parts of antioxidant (1010:168 =2:3) After mixing in proportion, put it into a high-speed mixer and stir for 3-5 minutes; put the mixed material into a twin-screw extruder, and then add 30 parts of glass fiber reinforcing age...

Embodiment 2

[0042] Preparation of nucleating agent masterbatch: take 60 parts of polyethylene terephthalate as carrier, add 10 parts of sodium stearate, 20 parts of ethylene-acrylic acid copolymer sodium salt, and 10 parts of nano-calcium carbonate. Prepare nucleating agent masterbatch by mixed extrusion granulation, and dry the pellets at 120°C for 6 hours for later use;

[0043]Extrusion molding: 50 parts of polyethylene terephthalate ([η]=0.67, Tm=250°C), 2 parts of the above-mentioned nucleating agent masterbatch, ethylene-methyl acrylate-glycidyl methacrylate 5 parts of copolymer, 10 parts of brominated polystyrene, 4 parts of antimony trioxide, 0.5 parts of lubricant ethylene bis stearamide, 0.2 parts of chain extender acrylic polymer, and 0.5 parts of antioxidant (1010:168 =2:3) After mixing in proportion, put it into a high-speed mixer and stir for 3-5 minutes; put the mixed material into a twin-screw extruder, and then add 30 parts of glass fiber reinforcing agent continuously, m...

Embodiment 3

[0046] Preparation of nucleating agent masterbatch: take 40 parts of polyethylene terephthalate as the carrier, add 20 parts of sodium benzoate, 30 parts of ethylene-acrylic acid copolymer sodium salt, and 10 parts of talcum powder, and extrude through twin-screw blending Prepare nucleating agent masterbatch by granulation, and dry the pellets at 120°C for 6 hours for later use;

[0047] Extrusion molding: 52 parts of polyethylene terephthalate ([η]=0.67, Tm=250°C), 3 parts of the above-mentioned nucleating agent masterbatch, ethylene-methyl acrylate-glycidyl methacrylate 4 parts of copolymer, 10 parts of decabromodiphenylethane, 3 parts of antimony trioxide, 0.5 parts of lubricant ethylene bisstearamide, 0.2 parts of chain extender acrylic polymer, and 0.5 parts of antioxidant (1010: 168=2:3) After mixing in proportion, put it into a high-speed mixer and stir for 3-5 minutes; add the mixed material into a twin-screw extruder, and then continuously add 30 parts of glass fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com