Thermoplastic resin composition and moldings thereof

A thermoplastic resin and composition technology, which is applied in the field of thermoplastic resin composition and its molded body, can solve the problems of impact resistance decline, vinyl chloride thermal decomposition, torque increase, etc., and achieve high impact resistance and good surface gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

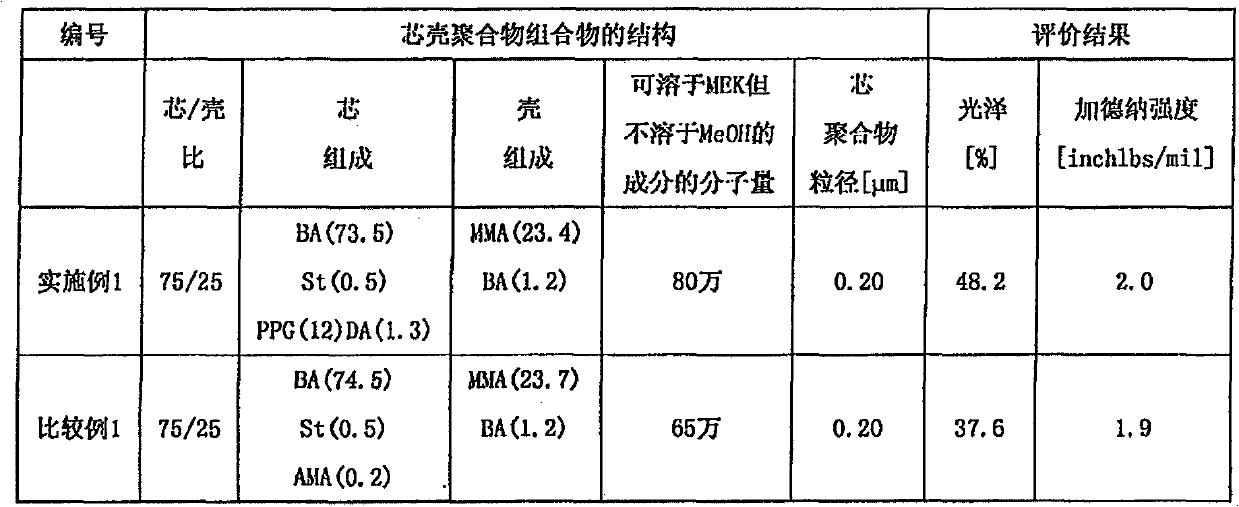

Embodiment 1

[0074] (Preparation of Core Shell Polymer Composition A-1)

[0075] In the glass reactor that has the adding device of thermometer, stirrer, reflux cooler, nitrogen flow inlet, monomer and emulsifier, add the sodium lauryl sulfate aqueous solution 60g of deionized water 2500g, 1.0% by weight concentration, under nitrogen While stirring in the stream, the temperature was raised to 50°C.

[0076] Then, an emulsified solution consisting of 10 g of butyl acrylate (hereinafter referred to as BA), 10 g of styrene (hereinafter referred to as St), 4 g of a 10% by weight aqueous solution of sodium lauryl sulfate, and 60 g of deionized water was added thereto. monomer mixture.

[0077] Then, 0.5 g of cumene hydroperoxide was added thereto, and after 10 minutes, a mixed solution obtained by dissolving 0.02 g of disodium edetate and 0.006 g of ferrous sulfate heptahydrate in 25 g of deionized water was added and 30 g of sodium formaldehyde sulfoxylate with a concentration of 5% by weigh...

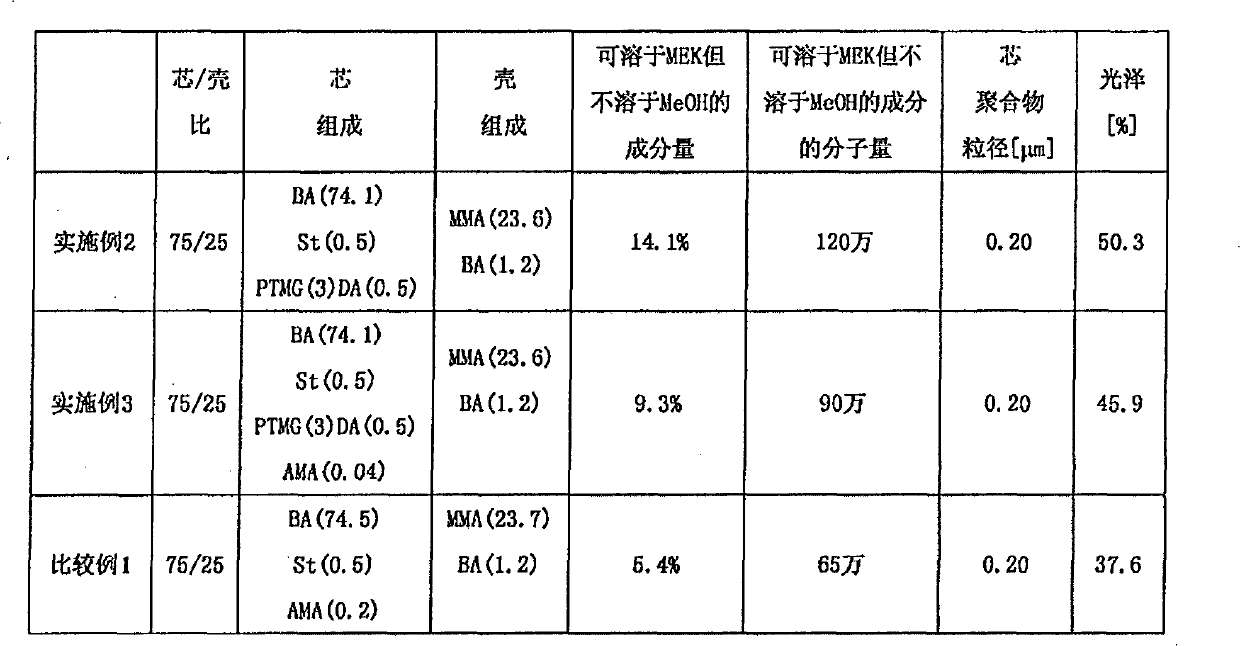

Embodiment 2

[0107] (Preparation of Core Shell Polymer Composition A-3)

[0108]In place of 26.6 g of PPG (12) DA, polytetramethylene glycol diacrylate (hereinafter referred to as PTMG (3) DA) whose main chain is a tetramethylene glycol chain with an average number of repeating units of 3 is used. ) except for 11.0 g, a core-shell polymer composition A-3 was prepared in the same manner as in Example 1. In addition, the volume average particle diameter of the acrylate polymer which is a core was 0.20 micrometers, and the polymerization conversion rate of the monomer component which forms an acrylate polymer was 99.6%. Through the above, the latex of the core-shell polymer composition A-3 composed of 75% by weight of the core component and 25% by weight of the shell component was obtained. In addition, the polymerization conversion rate of the total monomer component after completion|finish of polymerization was 99.9%.

[0109] (Preparation of White Resin Powder B-3 of Core Shell Polymer C...

Embodiment 3

[0118] (Preparation of Core Shell Polymer Composition A-4)

[0119] A core-shell polymer combination was prepared in the same manner as in Example 1, except that 11.0 g of PTMG (3) DA and 0.8 g of allyl methacrylate (hereinafter referred to as AMA) were used instead of 6.6 g of PPG (12) DA Object A-4. In addition, the volume average particle diameter of the acrylate polymer which is a core was 0.20 micrometers, and the polymerization conversion rate of the monomer component which forms an acrylate polymer was 99.6%. Through the above, the latex of the core-shell polymer composition A-4 composed of 75% by weight of the core component and 25% by weight of the shell component was obtained. Moreover, the polymerization conversion rate of the total monomer component after completion|finish of polymerization was 99.9%.

[0120] (Preparation of White Resin Powder B-4 of Core Shell Polymer Composition A-4)

[0121] Except having used the latex of the core-shell polymer composition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com